factory Outlets for Stainless Steel Cable 7×7 - Precision 304 Stainless Steel Strips – Saky Steel

factory Outlets for Stainless Steel Cable 7×7 - Precision 304 Stainless Steel Strips – Saky Steel Detail:

Specifications:AISI 304/304L,ASTM A240, AMS 5513/5511

·Finishes: 2B Mill (dull), #4 Brushed (appliances), #8 Mirror

·Applications: sanitary dairy, beverage and food product handling and processing, hospital equipment, marine hardware, kitchen appliances, back splashes, etc.

·Workability:Easy to Weld, Cut, Form and Machine with proper equipment

·Mechanical Properties: Nonmagnetic,Tensile = 85,000 +/-, Yield = 34,000 +/-, Brinell = 170

·How is it Measured thickness X width X length

·Available Stock Sizes:1ft x 4ft, 2ft x 2ft, 2ft x 4ft, 4ft x 4ft, 4ft x 8ft, 4ft x 10ft or Cut to Size

| C% | Si% | Mn% | P% | S% | Cr% | Ni% | N% | Mo% | Cu% |

| =0.08 | =1.0 | =2.0 | =0.045 | =0.03 | 18.0-20.0 | 8.0-10.0 | – | - | – |

| T*S | Y*S | Hardness | Elongation | |

| (Mpa) | (Mpa) | HRB | HB | (%) |

| =520 | =205 | – | – | =40 |

Stainless Steel Strip products from Sakysteel:

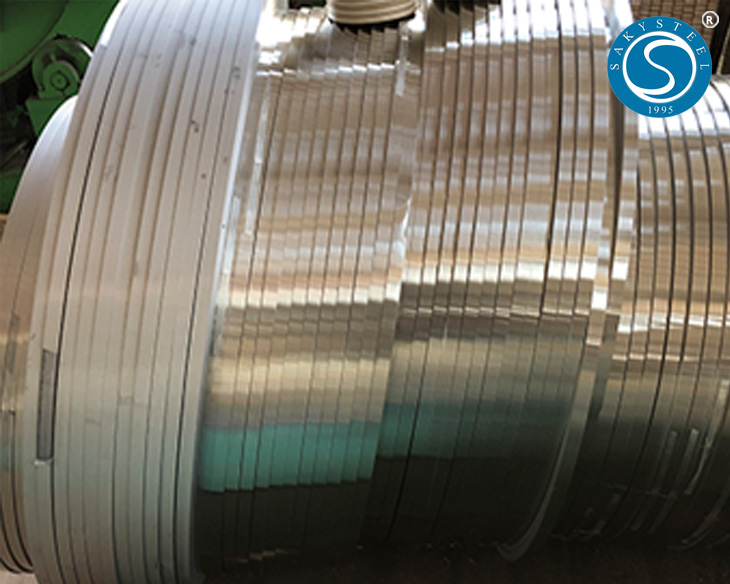

304 stainless steel strip manufacturers 304 stainless steel strip manufacturers |

304 stainless steel strip suppliers 304 stainless steel strip suppliers |

304 stainless steel strip price 304 stainless steel strip price |

304 stainless steel strip for sale 304 stainless steel strip for sale |

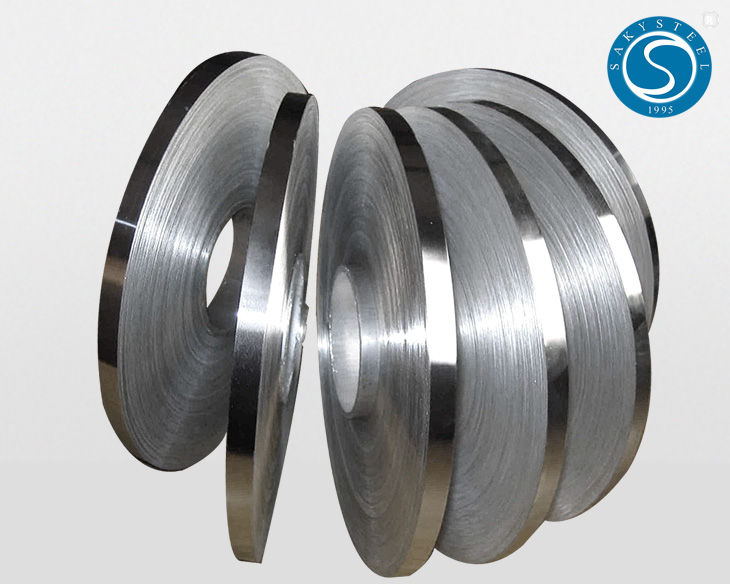

Description of 304 Stainless Steel strip

| Product | Stainless Steel Strip soft hardness 1/2 3/4 |

| Material Type | stainless steel, nonmagnetic. |

| Material Origin | Sakysteel,TISCO, BAOSTEEL, JISCO,POSCO |

| Grade | 200series,300series,400series |

| Technology | Cold Rolling & Hot Rolling |

| Thickness | 0.1mm to 100mm |

| Width | 3mm to 600mm |

| Length | customized size |

| Surface | BA, 2B, 2D, 4K, 6K, 8K, NO.4, HL, SB, Embossed |

| Edge | Mill Edge, Slit Edge |

| Other Choices | Leveling: improve flatness, esp. for items with high flatness request. |

| Skin-Pass: improve flatness, higher brightness | |

| Strip Slitting: any width from 10mm to 200mm | |

| Sheets Cutting: Square Sheets, Retangle Sheets, Circles, Other Shapes | |

| Protection | 1. Inter paper available |

| 2. PVC protecting film available | |

| Packing | Water-proof paper + Edge Protection + Wooden Pallets |

| Production Time | 20-45 days depending on processing requirement & business season |

| Payment Term | T/T, Irrevocable L/C at sight |

Surface of SS 304 strip

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

More grades of Stainless strip

| Type | Grade | Grade | Chemical Component % | ||||

| Austenitic stainless steel | C | Cr | Ni | Mn | |||

| 201 | 1Cr17Mn6Ni5N | =0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ||

| 201L | 03Cr17Mn6Ni5N | =0.030 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ||

| 202 | 1Cr18Mn8Ni5N | =0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ||

| 204 | 03Cr16Mn8Ni2N | =0.030 | 15.00-17.00 | 1.50-3.50 | 7.00-9.00 | ||

| 1Cr18Mn10Ni5Mo3N | =0.10 | 17.00-19.00 | 4.00-6.00 | 8.50-12.00 | |||

| 2Cr13Mn9Ni4 | 0.15-0.25 | 12.00-14.00 | 3.70-5.00 | 8.00-10.00 | |||

| 2Cr15Mn15Ni2N | 0.15-0.25 | 14.00-16.00 | 1.50-3.00 | 14.00-16.00 | |||

| 1Cr18Mn10Ni5Mo3N | =0.15 | 17.00-19.00 | 4.00-6.00 | 8.50-12.00 | |||

| 301 | 1Cr17Ni7 | =0.15 | 16.00-18.00 | 6.00-8.00 | =2.00 | ||

| 302 | 1Cr18Ni9 | =0.15 | 17.00-19.00 | 8.00-10.00 | =2.00 | ||

| 303 | Y1Cr18Ni9 | =0.15 | 17.00-19.00 | 8.00-10.00 | =2.00 | ||

| 303se | Y1Cr18Ni9Se | =0.15 | 17.00-19.00 | 8.00-10.00 | =2.00 | ||

| 304 | 0Cr18Ni9 | =0.07 | 17.00-19.00 | 8.00-10.00 | =2.00 | ||

| 304L | 00Cr19Ni10 | =0.030 | 18.00-20.00 | 8.00-10.00 | =2.00 | ||

| 304N1 | 0Cr19Ni9N | =0.08 | 18.00-20.00 | 7.00-10.50 | =2.00 | ||

| 304N2 | 0Cr18Ni10NbN | =0.08 | 18.00-20.00 | 7.50-10.50 | =2.00 | ||

| 304LN | 00Cr18Ni10N | =0.030 | 17.00-19.00 | 8.50-11.50 | =2.00 | ||

| 305 | 1Cr18Ni12 | =0.12 | 17.00-19.00 | 10.50-13.00 | =2.00 | ||

| 309S | 0Cr23Ni13 | =0.08 | 22.00-24.00 | 12.00-15.00 | =2.00 | ||

| 310S | 0Cr25Ni20 | =0.08 | 24.00-26.00 | 19.00-22.00 | =2.00 | ||

| 316 | 0Cr17Ni12Mo2 | =0.08 | 16.00-18.50 | 10.00-14.00 | =2.00 | ||

| 1Cr18Ni12Mo2Ti6) | =0.12 | 16.00-19.00 | 11.00-14.00 | =2.00 | |||

| 0Cr18Ni12Mo2Ti | =0.08 | 16.00-19.00 | 11.00-14.00 | =2.00 | |||

| 316L | 00Cr17Ni14Mo2 | =0.030 | 16.00-18.00 | 12.00-15.00 | =2.00 | ||

| 316N | 0Cr17Ni12Mo2N | =0.08 | 16.00-18.00 | 10.00-14.00 | =2.00 | ||

| 316N | 00Cr17Ni13Mo2N | =0.030 | 16.00-18.50 | 10.50-14.50 | =2.00 | ||

| 316J1 | 0Cr18Ni12Mo2Cu2 | =0.08 | 17.00-19.00 | 10.00-14.50 | =2.00 | ||

| 316J1L | 00Cr18Ni14Mo2Cu2 | =0.030 | 17.00-19.00 | 12.00-16.00 | =2.00 | ||

| 317 | 0Cr19Ni13Mo3 | =0.12 | 18.00-20.00 | 11.00-15.00 | =2.00 | ||

| 317L | 00Cr19Ni13Mo3 | =0.08 | 18.00-20.00 | 11.00-15.00 | =2.00 | ||

| 1Cr18Ni12Mo3Ti6 | =0.12 | 16.00-19.00 | 11.00-14.00 | =2.00 | |||

| 0Cr18Ni12Mo3Ti | =0.08 | 16.00-19.00 | 11.00-14.00 | =2.00 | |||

| 317J1 | 0Cr18Ni16Mo5 | =0.040 | 16.00-19.00 | 15.00-17.00 | =2.00 | ||

| 321 | 1Cr18Ni9Ti6 | =0.12 | 17.00-19.00 | 8.00-11.00 | =2.00 | ||

| 0Cr18Ni10Ti | =0.08 | 17.00-19.00 | 9.00-12.00 | =2.00 | |||

| 347 | 0Cr18Ni11Nb | =0.08 | 17.00-19.00 | 9.00-13.00 | =2.00 | ||

| XM7 | 0Cr18Ni9Cu3 | =0.08 | 17.00-19.00 | 8.50-10.50 | =2.00 | ||

| XM15J1 | 0Cr18Ni13Si4 | =0.08 | 15.00-20.00 | 11.50-15.00 | =2.00 | ||

| Austenite Ferrite Stainless Steel |

329J1 | 0Cr26Ni5Mo2 | =0.08 | 23.00-28.00 | 3.00-6.00 | =1.50 | =0.035 | =0.030 | 1.00-3.00 | =1.00 | - | - | 2) |

| 1Cr18Ni11Si4AlTi | 0.10-0.18 | 17.50-19.50 | 10.–120.. | =0.80 | =0.035 | =0.030 | - | 3.40-4.00 | - | - | Al 0.10-0.30; Ti 0.40-0.70 | ||

| 00Cr18Ni5MoSi2 | =0.030 | 18.00-19.50 | 4.50-5.50 | 1.00-2.00 | =0.035 | =0.030 | 2.50-3.00 | 1.30-2.00 | - | - | - |

| Ferrite Stainless Steel | 405 | 0Cr13Al | =0.08 | 11.50-14.50 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | Al 0.10-0.30 |

| 410L | 00Cr12 | =0.030 | 11.00-13.00 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 430 | 1Cr17 | =0.12 | 16.00-18.00 | 3) | =1.25 | =0.035 | =0.030 | - | =0.75 | - | - | - | |

| 430F | Y1Cr17 | =0.12 | 16.00-18.00 | 3) | =1.00 | =0.035 | =0.15 | 1) | =1.00 | - | - | - | |

| 434 | 1Cr17Mo | =0.12 | 16.00-18.00 | 3) | =1.00 | =0.035 | =0.030 | 0.75-1.25 | =1.00 | - | - | - | |

| 447J1 | 00Cr30Mo2 | =0.010 | 28.50-32.00 | - | =0.40 | =0.035 | =0.030 | 1.50-2.50 | =0.40 | - | =0.015 | - | |

| XM27 | 00Cr27Mo | =0.010 | 25.00-27.50 | - | =0.40 | =0.035 | =0.030 | 0.75-1.50 | =0.40 | - | =0.015 | - | |

| Martensite stainless steel | 403 | 1Cr12 | =0.15 | 11.50-13.00 | 3) | =1.00 | =0.035 | =0.030 | - | =0.50 | - | - | - |

| 410 | 1Cr13 | =0.15 | 11.50-13.50 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 405 | 0Cr13 | =0.08 | 11.50-13.50 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 416 | Y1Cr13 | =0.15 | 12.00-14.00 | 3) | =1.25 | =0.035 | =0.15 | 1) | =1.00 |

Product detail pictures:

Related Product Guide:

Stainless Steel in Modern Pubs and Bars

How to Save Time and Cost With a 316 Stainless Steel Bar

As a way to provide you advantage and enlarge our organization, we even have inspectors in QC Crew and guarantee you our greatest assistance and product or service for factory Outlets for Stainless Steel Cable 7×7 - Precision 304 Stainless Steel Strips – Saky Steel, The product will supply to all over the world, such as: United Kingdom , Latvia , Dubai , With the technology as the core, develop and produce high-quality products according to the diverse needs of the market. With this concept,the company will continue to develop products with high added values and continuously improve products,and will provide many customers with the best products and services!

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.