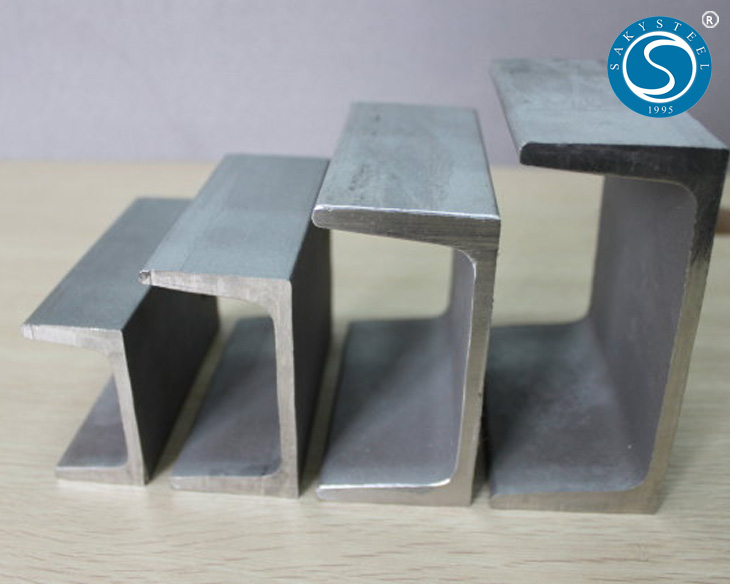

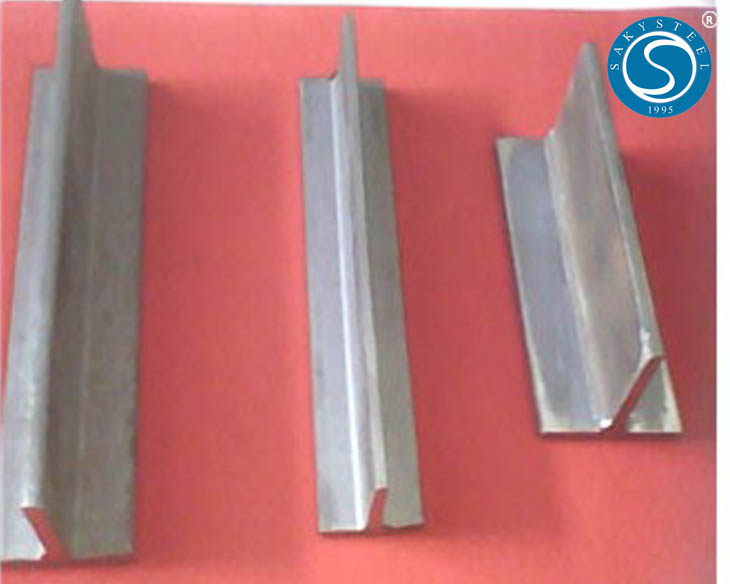

Factory Free sample Shower Support Bar - Stainless Steel T Section – Saky Steel

Factory Free sample Shower Support Bar - Stainless Steel T Section – Saky Steel Detail:

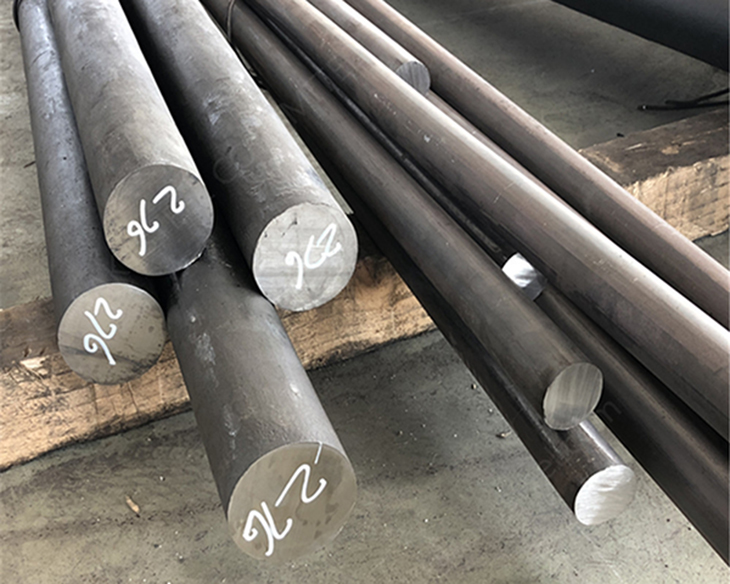

Stainless steel T bar,T section or Tee profile with grade 201,303,304,304L,316,316L,316TI,321,310S,410,430

Specifications of Stainless steel T bar:

| Standard | ASTM A276, A484, A479, A580, A582, JIS G4303, JIS G4311,DIN 1654-5,DIN 17440,KS D3706,GB/T 1220 |

| Material | 201,202,205,XM-19 etc. 301,303,304,304L,304H,309S,310S,314,316,316L,316Ti,317,321,321H,329,330,348 etc. 409,410,416,420,430,430F,431,440 2205,2507,S31803,2209,630,631,15-5PH,17-4PH,17-7PH,904L,F51,F55,253MA etc. |

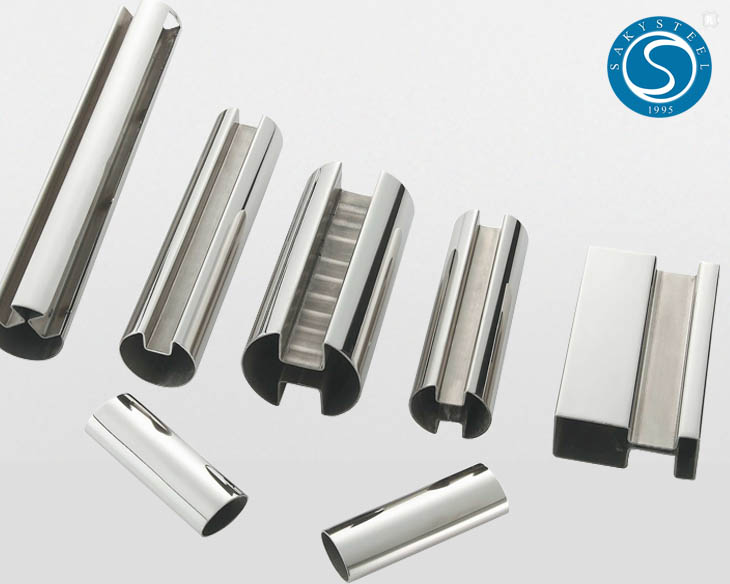

| Surface | Bright,Polishing,Pickled,Peeled,Black,Grinding,Mill,Mirror,Hairline etc |

| Technology | Cold Drawn,Hot Rolled,Forged |

| Specifications | as required |

| Tolerance | H9, H11, H13, K9, K11, K13 or as required |

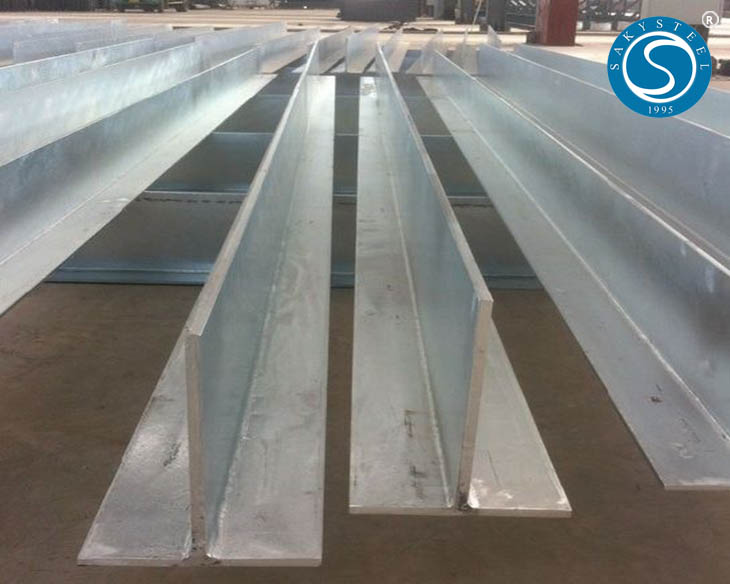

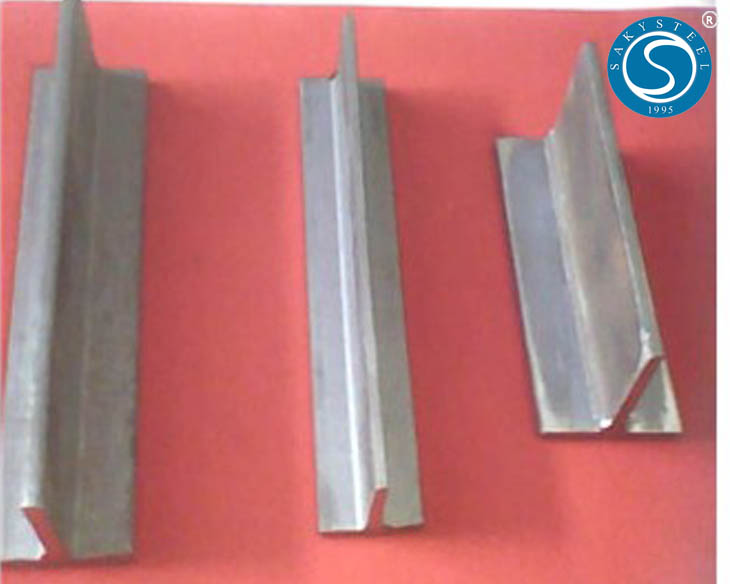

Stainless Steel T Section products from Sakysteel:

Stainless Steel T Section manufacturers Stainless Steel T Section manufacturers |

Stainless Steel T Section suppliers Stainless Steel T Section suppliers |

Weight of Stainless steel T bar

| Model | Weight | Model | Weight |

| 100*50*5*7 | 9.54 | 344*354*16*16 | 131 |

| 100*100*6*8 | 17.2 | 346*174*6*9 | 41.8 |

| 125*60*6*8 | 13.3 | 350*175*7*11 | 50 |

| 125*125*6.5*9 | 23.8 | 344*348*10*16 | 115 |

| 148*100*6*9 | 21.4 | 350*350*12*19 | 137 |

| 150*75*5*7 | 14.3 | 388*402*15*15 | 141 |

| 150*150*7*10 | 31.9 | 390*300*10*16 | 107 |

| 175*90*5*8 | 18.2 | 394*398*11*18 | 147 |

| 175*175*7.5*11 | 40.3 | 400*150*8*13 | 55.8 |

| 194*150*6*9 | 31.2 | 396*199*7*11 | 56.7 |

| 198*99*4.5*7 | 18.5 | 400*200*8*13 | 66 |

| 200*100*5.5*8 | 21.7 | 400*400*13*21 | 172 |

| 200*200*8*12 | 50.5 | 400*408*21*21 | 197 |

| 200*204*12*12 | 72.28 | 414*405*18*28 | 233 |

| 244*175*7*11 | 44.1 | 440*300*11*18 | 124 |

| 244*252*11*11 | 64.4 | 446*199*7*11 | 66.7 |

| 248*124*5*8 | 25.8 | 450*200*9-14 | 76.5 |

| 250*125*6*9 | 29.7 | 482*300*11*15 | 115 |

| 250*250*9*14 | 72.4 | 488*300*11*18 | 129 |

| 250*255*14*14 | 82.2 | 496*199*9*14 | 79.5 |

| 294*200*8*12 | 57.3 | 500*200*10*16 | 89.6 |

| 300*150*6.5*9 | 37.3 | 582*300*12*17 | 137 |

| 294*302*12*12 | 85 | 588*300*12*20 | 151 |

| 300*300*10*15 | 94.5 | 596*199*10*15 | 95.1 |

| 300*305*15*15 | 106 | 600*200*11*17 | 106 |

| 338*351*13*13 | 106 | 700*300*13*24 | 185 |

| 340*250*9*14 | 79.7 |

More grade of Stainless steel T bar

<td

| Type | Grade | Grade | Chemical Component % | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Other | |||

| Austenitic stainless steel | 201 | 1Cr17Mn6Ni5N | =0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | =0.060 | =0.030 | - | =1.00 | - | =0.25 | - |

| 201L | 03Cr17Mn6Ni5N | =0.030 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | =0.060 | =0.030 | =1.00 | =0.25 | ||||

| 202 | 1Cr18Mn8Ni5N | =0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | =0.060 | =0.030 | =1.00 | - | =0.25 | - | ||

| 204 | 03Cr16Mn8Ni2N | =0.030 | 15.00-17.00 | 1.50-3.50 | 7.00-9.00 | 0.15-0.30 | |||||||

| 1Cr18Mn10Ni5Mo3N | =0.10 | 17.00-19.00 | 4.00-6.00 | 8.50-12.00 | 2.80-3.50 | 0.20-0.30 | |||||||

| 2Cr13Mn9Ni4 | 0.15-0.25 | 12.00-14.00 | 3.70-5.00 | 8.00-10.00 | |||||||||

| 2Cr15Mn15Ni2N | 0.15-0.25 | 14.00-16.00 | 1.50-3.00 | 14.00-16.00 | 0.15-0.30 | ||||||||

| 1Cr18Mn10Ni5Mo3N | =0.15 | 17.00-19.00 | 4.00-6.00 | 8.50-12.00 | =0.060 | =0.030 | 2.8-3.5 | =1.00 | - | 0.20-0.30 | - | ||

| 301 | 1Cr17Ni7 | =0.15 | 16.00-18.00 | 6.00-8.00 | =2.00 | =0.065 | =0.030 | - | =1.00 | - | - | - | |

| 302 | 1Cr18Ni9 | =0.15 | 17.00-19.00 | 8.00-10.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 303 | Y1Cr18Ni9 | =0.15 | 17.00-19.00 | 8.00-10.00 | =2.00 | =0.20 | =0.030 | 1) | =1.00 | - | - | - | |

| 303se | Y1Cr18Ni9Se | =0.15 | 17.00-19.00 | 8.00-10.00 | =2.00 | =0.20 | =0.030 | - | =1.00 | - | - | Se=0.15 | |

| 304 | 0Cr18Ni9 | =0.07 | 17.00-19.00 | 8.00-10.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 304L | 00Cr19Ni10 | =0.030 | 18.00-20.00 | 8.00-10.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 304N1 | 0Cr19Ni9N | =0.08 | 18.00-20.00 | 7.00-10.50 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | 0.10-0.25 | - | |

| 304N2 | 0Cr18Ni10NbN | =0.08 | 18.00-20.00 | 7.50-10.50 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | 0.15-0.30 | Nb=0.15 | |

| 304LN | 00Cr18Ni10N | =0.030 | 17.00-19.00 | 8.50-11.50 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | 0.12-0.22 | - | |

| 305 | 1Cr18Ni12 | =0.12 | 17.00-19.00 | 10.50-13.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 309S | 0Cr23Ni13 | =0.08 | 22.00-24.00 | 12.00-15.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 310S | 0Cr25Ni20 | =0.08 | 24.00-26.00 | 19.00-22.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 316 | 0Cr17Ni12Mo2 | =0.08 | 16.00-18.50 | 10.00-14.00 | =2.00 | =0.035 | =0.030 | 2.00-3.00 | =1.00 | - | - | - | |

| 1Cr18Ni12Mo2Ti6) | =0.12 | 16.00-19.00 | 11.00-14.00 | =2.00 | =0.035 | =0.030 | 1.80-2.50 | =1.00 | - | - | Ti5(C%-0.02)~0.08 | ||

| 0Cr18Ni12Mo2Ti | =0.08 | 16.00-19.00 | 11.00-14.00 | =2.00 | =0.035 | =0.030 | 1.80-2.50 | =1.00 | - | - | Ti5*C%-0.70 | ||

| 316L | 00Cr17Ni14Mo2 | =0.030 | 16.00-18.00 | 12.00-15.00 | =2.00 | =0.035 | =0.030 | 2.00-3.00 | =1.00 | - | - | - | |

| 316N | 0Cr17Ni12Mo2N | =0.08 | 16.00-18.00 | 10.00-14.00 | =2.00 | =0.035 | =0.030 | 2.00-3.00 | =1.00 | - | 0.10-0.22 | - | |

| 316N | 00Cr17Ni13Mo2N | =0.030 | 16.00-18.50 | 10.50-14.50 | =2.00 | =0.035 | =0.030 | 2.00-3.00 | =1.00 | - | 0.12-0.22 | - | |

| 316J1 | 0Cr18Ni12Mo2Cu2 | =0.08 | 17.00-19.00 | 10.00-14.50 | =2.00 | =0.035 | =0.030 | 1.20-2.75 | =1.00 | 1.00-2.50 | - | - | |

| 316J1L | 00Cr18Ni14Mo2Cu2 | =0.030 | 17.00-19.00 | 12.00-16.00 | =2.00 | =0.035 | =0.030 | 1.20-2.75 | =1.00 | 1.00-2.50 | - | - | |

| 317 | 0Cr19Ni13Mo3 | =0.12 | 18.00-20.00 | 11.00-15.00 | =2.00 | =0.035 | =0.030 | 3.00-4.00 | =1.00 | - | - | - | |

| 317L | 00Cr19Ni13Mo3 | =0.08 | 18.00-20.00 | 11.00-15.00 | =2.00 | =0.035 | =0.030 | 3.00-4.00 | =1.00 | - | - | - | |

| 1Cr18Ni12Mo3Ti6 | =0.12 | 16.00-19.00 | 11.00-14.00 | =2.00 | =0.035 | =0.030 | 2.50-3.50 | =1.00 | - | - | Ti5(C%-0.02)~0.08 | ||

| 0Cr18Ni12Mo3Ti | =0.08 | 16.00-19.00 | 11.00-14.00 | =2.00 | =0.035 | =0.030 | 2.50-3.50 | =1.00 | - | - | Ti5*C%-0.70 | ||

| 317J1 | 0Cr18Ni16Mo5 | =0.040 | 16.00-19.00 | 15.00-17.00 | =2.00 | =0.035 | =0.030 | 4.00-6.00 | =1.00 | - | - | - | |

| 321 | 1Cr18Ni9Ti6 | =0.12 | 17.00-19.00 | 8.00-11.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | Ti5(C%-0.02)~0.08 | |

| 0Cr18Ni10Ti | =0.08 | 17.00-19.00 | 9.00-12.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | Ti=5*C% | ||

| 347 | 0Cr18Ni11Nb | =0.08 | 17.00-19.00 | 9.00-13.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | Nb=10*C% | |

| XM7 | 0Cr18Ni9Cu3 | =0.08 | 17.00-19.00 | 8.50-10.50 | =2.00 | =0.035 | =0.030 | - | =1.00 | 3.00-4.00 | - | - | |

| XM15J1 | 0Cr18Ni13Si4 | =0.08 | 15.00-20.00 | 11.50-15.00 | =2.00 | =0.035 | =0.030 | - | 3.00-5.00 | - | - | 2) | |

| Austenite | 329J1 | 0Cr26Ni5Mo2 | =0.08 | 23.00-28.00 | 3.00-6.00 | =1.50 | =0.035 | =0.030 | 1.00-3.00 | =1.00 | - | - | 2) |

| | | 1Cr18Ni11Si4AlTi | 0.10-0.18 | 17.50-19.50 | 10.–120.. | =0.80 | =0.035 | =0.030 | - | 3.40-4.00 | - | - | Al 0.10-0.30; Ti 0.40-0.70 | |

| Ferrite Stainless Steel | 00Cr18Ni5MoSi2 | =0.030 | 18.00-19.50 | 4.50-5.50 | 1.00-2.00 | =0.035 | =0.030 | 2.50-3.00 | 1.30-2.00 | - | - | - | |

| Ferrite Stainless Steel | 405 | 0Cr13Al | =0.08 | 11.50-14.50 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | Al 0.10-0.30 |

| 410L | 00Cr12 | =0.030 | 11.00-13.00 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 430 | 1Cr17 | =0.12 | 16.00-18.00 | 3) | =1.25 | =0.035 | =0.030 | - | =0.75 | - | - | - | |

| 430F | Y1Cr17 | =0.12 | 16.00-18.00 | 3) | =1.00 | =0.035 | =0.15 | 1) | =1.00 | - | - | - | |

| 434 | 1Cr17Mo | =0.12 | 16.00-18.00 | 3) | =1.00 | =0.035 | =0.030 | 0.75-1.25 | =1.00 | - | - | - | |

| 447J1 | 00Cr30Mo2 | =0.010 | 28.50-32.00 | - | =0.40 | =0.035 | =0.030 | 1.50-2.50 | =0.40 | - | =0.015 | - | |

| XM27 | 00Cr27Mo | =0.010 | 25.00-27.50 | - | =0.40 | =0.035 | =0.030 | 0.75-1.50 | =0.40 | - | =0.015 | - | |

| Martensite stainless steel | 403 | 1Cr12 | =0.15 | 11.50-13.00 | 3) | =1.00 | =0.035 | =0.030 | - | =0.50 | - | - | - |

| 410 | 1Cr13 | =0.15 | 11.50-13.50 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 405 | 0Cr13 | =0.08 | 11.50-13.50 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 416 | Y1Cr13 | =0.15 | 12.00-14.00 | 3) | =1.25 | =0.035 | =0.15 | 1) | =1.00 | - | - | - | |

| 410J1 | 1Cr13Mo | =0.08-0.18 | 11.50-14.00 | 3) | =1.00 | =0.035 | =0.030 | 0.30-0.60 | =0.60 | - | - | - | |

| 420J1 | 2Cr13 | 0.16-0.25 | 12.00-14.00 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 420J2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 420F | Y3Cr13 | 0.26-0.40 | 12.00-14.00 | 3) | =1.25 | =0.035 | =0.15 | 1) | =1.00 | - | - | - | |

| 3Cr13Mo | 0.28-0.35 | 12.00-14.00 | 3) | =1.00 | =0.035 | =0.030 | 0.50-1.00 | =0.80 | - | - | - | ||

| 4Cr13 | 0.36-0.45 | 12.00-14.00 | 3) | =0.80 | =0.035 | =0.030 | - | =0.60 | - | - | - | ||

| 431 | 1Cr17Ni2 | 0.11-0.17 | 16.00-18.00 | 1.50-2.50 | =0.80 | =0.035 | =0.030 | - | =0.80 | - | - | - | |

| 440A | 7Cr17 | 0.60-0.75 | 16.00-18.00 | 3) | =1.00 | =0.035 | =0.030 | 4) | =1.00 | - | - | - | |

| 440B | 8Cr17 | 0.75-0.95 | 16.00-18.00 | 3) | =1.00 | =0.035 | =0.030 | 4) | =1.00 | - | - | - | |

| 9Cr18 | 0.90-1.00 | 17.00-19.00 | 3) | =0.80 | =0.035 | =0.030 | 4) | =0.80 | - | - | - | ||

| 440C | 11Cr17 | 0.95-1.20 | 16.00-18.00 | 3) | =1.00 | =0.035 | =0.030 | 4) | =1.00 | - | - | - | |

| 440F | Y11Cr17 | 0.95-1.20 | 16.00-18.00 | 3) | =1.25 | =0.035 | =0.15 | 4) | =1.00 | - | - | - | |

| 9Cr18Mo | 0.95-1.10 | 16.00-18.00 | 3) | =0.80 | =0.035 | =0.030 | 0.40-0.70 | =0.80 | - | - | - | ||

| 9Cr18MoV | 0.85-0.95 | 17.00-19.00 | 3) | =0.80 | =0.035 | =0.030 | 1.00-1.30 | =0.80 | - | - | V0.07-0.12 | ||

| PH Stainless Steel | 630 | 0Cr17Ni4Cu4Nb | =0.07 | 15.50-17.50 | 6.50-7.50 | =1.00 | =0.035 | =0.030 | - | =1.00 | 3.00-5.00 | - | Nb 0.15-0.45 |

| 631 | 0Cr17Ni7Al | =0.09 | 16.00-18.00 | 6.50-7.50 | =1.00 | =0.035 | =0.030 | - | =1.00 | =0.50 | - | Al 0.75-1.50 | |

Product detail pictures:

Related Product Guide:

Stainless Steel in Modern Pubs and Bars

Stainless Steel Bars – Production, Importance, and Uses

We have been experienced manufacturer. Wining the majority of the crucial certifications of its market for Factory Free sample Shower Support Bar - Stainless Steel T Section – Saky Steel, The product will supply to all over the world, such as: United States , Indonesia , Nicaragua , We have a dedicated and aggressive sales team, and many branches, catering to our customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.