Factory best selling Hot Rolled Hexagon Bar - Stainless Steel Pipe Polished – Saky Steel

Factory best selling Hot Rolled Hexagon Bar - Stainless Steel Pipe Polished – Saky Steel Detail:

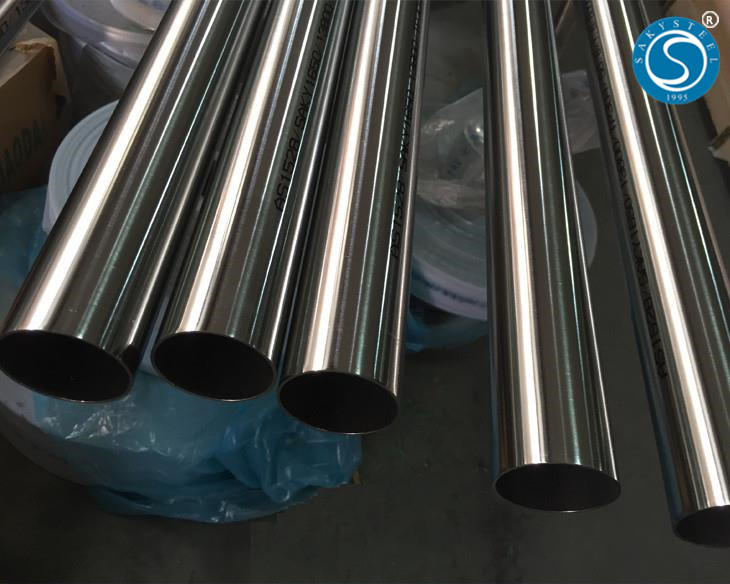

Specifications of stainless steel pipe polished

| 1. Product | Stainless Steel Welded Pipe |

| 2. Material | 201,202,301,302,304,309,310S,316L,321,347,410,430,409Letc. |

| 3. Standard | ASTM, ASME, DIN, EN, ISO,JIS, GOST, etc. |

| 4. Size range | OD: from 6mm to 1219mm (NPS from 1/8” to 40”) |

| WT: from 0.7mm to 38mm (Schedule from 5S to XXS) | |

| Length: fix length or un-fix length, Max 30meters | |

| 5. Produce process | welded,hot bending;resistance welding;Thermal expansion etc. |

| 6. Surface | 2B,Pickled,180G, 320G, Satin, Hairline,400G, 500G, 600G |

| ,800G, Mirror finish | |

| 7. Marking | SAKY, GRADE, Seamless, Standard, Size, Heat NO. |

| 8. Package | Bundles with waterproof cloth outside. |

| or plywood box. | |

| 9. Length | 5.8m,6m,12m or as required |

| Typical mechanical properties for 304 stainless steel alloys | |||||

| Grade | Tensile Strength (MPa) | Compression Strength (MPa) | Proof Stress 0.2% (MPa) | Elongation A5 (%) | Hardness Rockwell B |

| 304 | 520-720 | 210 | 210 | 45 Min | 92 |

| 304L | 500-670 | 200 | 45 Min | ||

| 304H | 520-720 | 210 | 45Min | ||

Grades of stainless steel pipe polished:

| Type | Grade | Grade | Chemical Component % | ||||

| Austenitic stainless steel | C | Cr | Ni | Mn | |||

| 201 | 1Cr17Mn6Ni5N | =0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ||

| 201L | 03Cr17Mn6Ni5N | =0.030 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ||

| 202 | 1Cr18Mn8Ni5N | =0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ||

| 204 | 03Cr16Mn8Ni2N | =0.030 | 15.00-17.00 | 1.50-3.50 | 7.00-9.00 | ||

| 1Cr18Mn10Ni5Mo3N | =0.10 | 17.00-19.00 | 4.00-6.00 | 8.50-12.00 | |||

| 2Cr13Mn9Ni4 | 0.15-0.25 | 12.00-14.00 | 3.70-5.00 | 8.00-10.00 | |||

| 2Cr15Mn15Ni2N | 0.15-0.25 | 14.00-16.00 | 1.50-3.00 | 14.00-16.00 | |||

| 1Cr18Mn10Ni5Mo3N | =0.15 | 17.00-19.00 | 4.00-6.00 | 8.50-12.00 | |||

| 301 | 1Cr17Ni7 | =0.15 | 16.00-18.00 | 6.00-8.00 | =2.00 | ||

| 302 | 1Cr18Ni9 | =0.15 | 17.00-19.00 | 8.00-10.00 | =2.00 | ||

| 303 | Y1Cr18Ni9 | =0.15 | 17.00-19.00 | 8.00-10.00 | =2.00 | ||

| 303se | Y1Cr18Ni9Se | =0.15 | 17.00-19.00 | 8.00-10.00 | =2.00 | ||

| 304 | 0Cr18Ni9 | =0.07 | 17.00-19.00 | 8.00-10.00 | =2.00 | ||

| 304L | 00Cr19Ni10 | =0.030 | 18.00-20.00 | 8.00-10.00 | =2.00 | ||

| 304N1 | 0Cr19Ni9N | =0.08 | 18.00-20.00 | 7.00-10.50 | =2.00 | ||

| 304N2 | 0Cr18Ni10NbN | =0.08 | 18.00-20.00 | 7.50-10.50 | =2.00 | ||

| 304LN | 00Cr18Ni10N | =0.030 | 17.00-19.00 | 8.50-11.50 | =2.00 | ||

| 305 | 1Cr18Ni12 | =0.12 | 17.00-19.00 | 10.50-13.00 | =2.00 | ||

| 309S | 0Cr23Ni13 | =0.08 | 22.00-24.00 | 12.00-15.00 | =2.00 | ||

| 310S | 0Cr25Ni20 | =0.08 | 24.00-26.00 | 19.00-22.00 | =2.00 | ||

| 316 | 0Cr17Ni12Mo2 | =0.08 | 16.00-18.50 | 10.00-14.00 | =2.00 | ||

| 1Cr18Ni12Mo2Ti6) | =0.12 | 16.00-19.00 | 11.00-14.00 | =2.00 | |||

| 0Cr18Ni12Mo2Ti | =0.08 | 16.00-19.00 | 11.00-14.00 | =2.00 | |||

| 316L | 00Cr17Ni14Mo2 | =0.030 | 16.00-18.00 | 12.00-15.00 | =2.00 | ||

| 316N | 0Cr17Ni12Mo2N | =0.08 | 16.00-18.00 | 10.00-14.00 | =2.00 | ||

| 316N | 00Cr17Ni13Mo2N | =0.030 | 16.00-18.50 | 10.50-14.50 | =2.00 | ||

| 316J1 | 0Cr18Ni12Mo2Cu2 | =0.08 | 17.00-19.00 | 10.00-14.50 | =2.00 | ||

| 316J1L | 00Cr18Ni14Mo2Cu2 | =0.030 | 17.00-19.00 | 12.00-16.00 | =2.00 | ||

| 317 | 0Cr19Ni13Mo3 | =0.12 | 18.00-20.00 | 11.00-15.00 | =2.00 | ||

| 317L | 00Cr19Ni13Mo3 | =0.08 | 18.00-20.00 | 11.00-15.00 | =2.00 | ||

| 1Cr18Ni12Mo3Ti6 | =0.12 | 16.00-19.00 | 11.00-14.00 | =2.00 | |||

| 0Cr18Ni12Mo3Ti | =0.08 | 16.00-19.00 | 11.00-14.00 | =2.00 | |||

| 317J1 | 0Cr18Ni16Mo5 | =0.040 | 16.00-19.00 | 15.00-17.00 | =2.00 | ||

| 321 | 1Cr18Ni9Ti6 | =0.12 | 17.00-19.00 | 8.00-11.00 | =2.00 | ||

| 0Cr18Ni10Ti | =0.08 | 17.00-19.00 | 9.00-12.00 | =2.00 | |||

| 347 | 0Cr18Ni11Nb | =0.08 | 17.00-19.00 | 9.00-13.00 | =2.00 | ||

| XM7 | 0Cr18Ni9Cu3 | =0.08 | 17.00-19.00 | 8.50-10.50 | =2.00 | ||

| XM15J1 | 0Cr18Ni13Si4 | =0.08 | 15.00-20.00 | 11.50-15.00 | =2.00 | ||

| Austenite Ferrite Stainless Steel |

329J1 | 0Cr26Ni5Mo2 | =0.08 | 23.00-28.00 | 3.00-6.00 | =1.50 | =0.035 | =0.030 | 1.00-3.00 | =1.00 | - | - | 2) |

| 1Cr18Ni11Si4AlTi | 0.10-0.18 | 17.50-19.50 | 10.–120.. | =0.80 | =0.035 | =0.030 | - | 3.40-4.00 | - | - | Al 0.10-0.30; Ti 0.40-0.70 | ||

| 00Cr18Ni5MoSi2 | =0.030 | 18.00-19.50 | 4.50-5.50 | 1.00-2.00 | =0.035 | =0.030 | 2.50-3.00 | 1.30-2.00 | - | - | - | ||

| Ferrite Stainless Steel | 405 | 0Cr13Al | =0.08 | 11.50-14.50 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | Al 0.10-0.30 |

| 410L | 00Cr12 | =0.030 | 11.00-13.00 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 430 | 1Cr17 | =0.12 | 16.00-18.00 | 3) | =1.25 | =0.035 | =0.030 | - | =0.75 | - | - | - | |

| 430F | Y1Cr17 | =0.12 | 16.00-18.00 | 3) | =1.00 | =0.035 | =0.15 | 1) | =1.00 | - | - | - | |

| 434 | 1Cr17Mo | =0.12 | 16.00-18.00 | 3) | =1.00 | =0.035 | =0.030 | 0.75-1.25 | =1.00 | - | - | - | |

| 447J1 | 00Cr30Mo2 | =0.010 | 28.50-32.00 | - | =0.40 | =0.035 | =0.030 | 1.50-2.50 | =0.40 | - | =0.015 | - | |

| XM27 | 00Cr27Mo | =0.010 | 25.00-27.50 | - | =0.40 | =0.035 | =0.030 | 0.75-1.50 | =0.40 | - | =0.015 | - |

| Martensite stainless steel | 403 | 1Cr12 | =0.15 | 11.50-13.00 | 3) | =1.00 | =0.035 | =0.030 | - | =0.50 | - | - | - |

| 410 | 1Cr13 | =0.15 | 11.50-13.50 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 405 | 0Cr13 | =0.08 | 11.50-13.50 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 416 | Y1Cr13 | =0.15 | 12.00-14.00 | 3) | =1.25 | =0.035 | =0.15 | 1) | =1.00 | - | - | - | |

| 410J1 | 1Cr13Mo | =0.08-0.18 | 11.50-14.00 | 3) | =1.00 | =0.035 | =0.030 | 0.30-0.60 | =0.60 | - | - | - | |

| 420J1 | 2Cr13 | 0.16-0.25 | 12.00-14.00 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 420J2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 420F | Y3Cr13 | 0.26-0.40 | 12.00-14.00 | 3) | =1.25 | =0.035 | =0.15 | 1) | =1.00 | - | - | - | |

| 3Cr13Mo | 0.28-0.35 | 12.00-14.00 | 3) | =1.00 | =0.035 | =0.030 | 0.50-1.00 | =0.80 | - | - | - | ||

| 4Cr13 | 0.36-0.45 | 12.00-14.00 | 3) | =0.80 | =0.035 | =0.030 | - | =0.60 | - | - | - | ||

| 431 | 1Cr17Ni2 | 0.11-0.17 | 16.00-18.00 | 1.50-2.50 | =0.80 | =0.035 | =0.030 | - | =0.80 | - | - | - | |

| 440A | 7Cr17 | 0.60-0.75 | 16.00-18.00 | 3) | =1.00 | =0.035 |

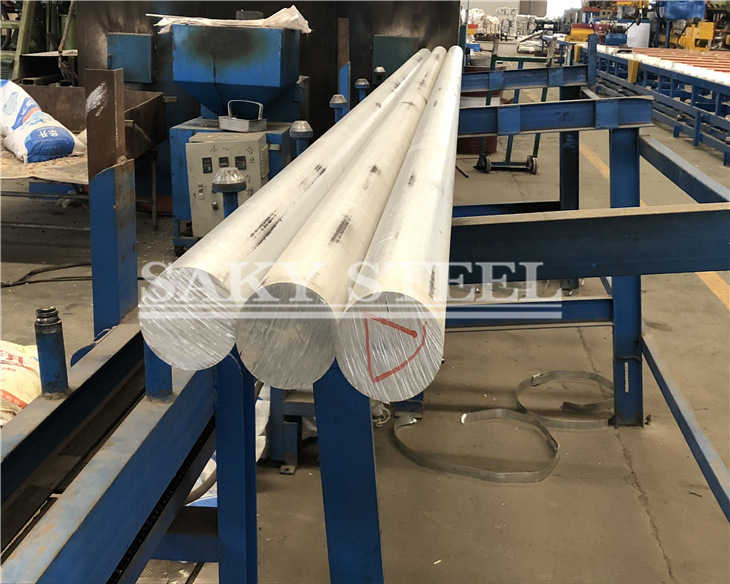

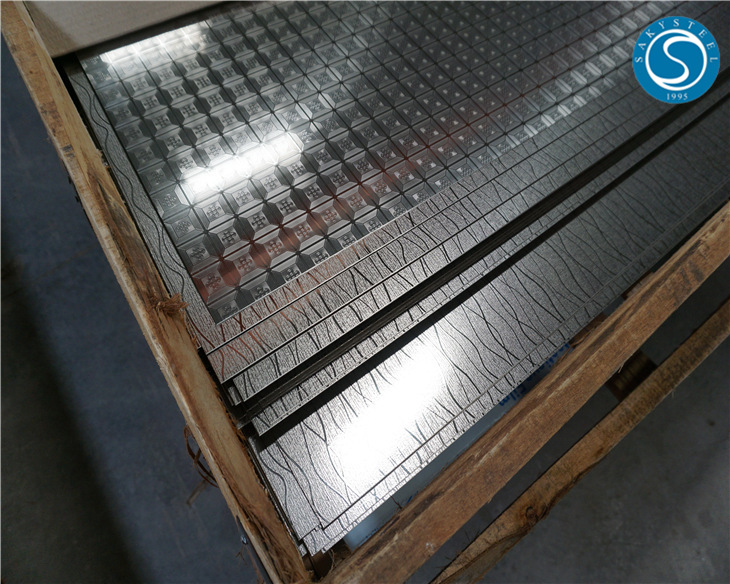

Product detail pictures:

Related Product Guide:

Stainless Steel Bars – Production, Importance, and Uses

How to Save Time and Cost With a 316 Stainless Steel Bar

We aim to find out high quality disfigurement in the generation and provide the most effective services to domestic and abroad clients wholeheartedly for Factory best selling Hot Rolled Hexagon Bar - Stainless Steel Pipe Polished – Saky Steel, The product will supply to all over the world, such as: Cape Town , Hungary , Algeria , They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a should for you of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we are going to possess a vibrant prospect and to be distributed all over the world within the years to come.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.