EHS WIRE Galvanized steel Wire Rope

Short Description:

EHS (Extra High Strength) galvanized steel wire rope is a robust and durable type of wire rope used in various applications that require high tensile strength and corrosion resistance.

EHS Galvanized Steel wire rope:

Using high-quality carbon steel, the steel wire istwisted into a rope after hot-dip galvanizing andelectro-galvanizing. The product has no burrs, nobreaking rope, and consistent color, It has goodcorrosion resistance, good tensile performanceand oxidation resistance. Able to work normally.in harsh environments.The galvanization process involves coating the wire with a layer of zinc, which provides excellent corrosion resistance, making it suitable for outdoor and marine environments.The combination of high tensile strength and corrosion resistance makes EHS wire rope highly durable.Despite its high strength, it maintains a level of flexibility that allows for ease of use in various applications.The enhanced strength and durability contribute to higher safety margins in critical applications.

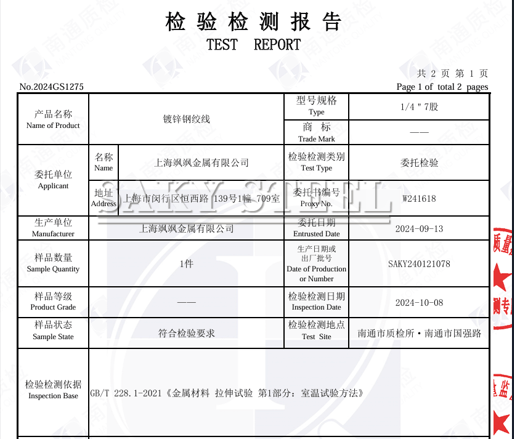

Specifications Of Galvanized steel Strand:

| Grade | 45#,65#,70#etc. |

| Specifications | YB/T 5004 |

| Diameter Range | 0.15 mm to 50.0mm. |

| Tolerance | ±0.01mm |

| Construction | 1×7, 1×19, 6×7, 6×19, 6×37, 7×7, 7×19, 7×37 |

| Galvanization | Electro-galvanized or hot-dip galvanized |

| Tensile Strength | Typically between 1770 MPa to 2160 MPa, varies with specification and steel grade |

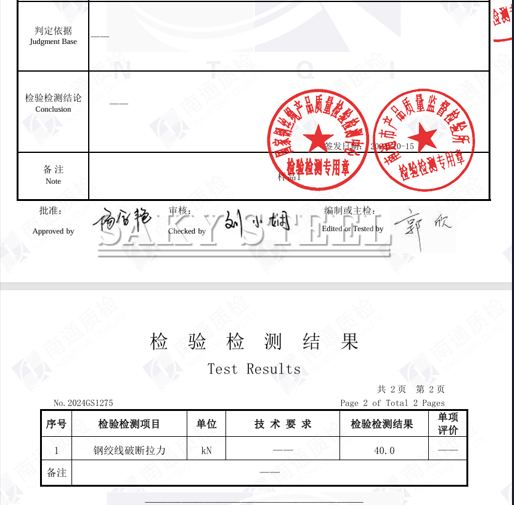

| Breaking Load | Varies with diameter and construction; e.g., approximately 30kN for 6mm diameter, 70kN for 10mm diameter |

| Length | 100m / reel, 200m / reel 250m / reel, 305m / reel, 1000m / reel |

| Core | FC, SC, IWRC, PP |

| Surface | Bright |

| Raw Materail | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

EHS Wire rope Production Process:

After drawing and galvanizing, the galvanized steel wire is made. Before galvanizing, the steel wire needs to pass through a pool to make the steel wire smooth and ensure the quality of galvanizing.

① Raw material: steel wire rod

② Drawing process

③ Galvanizing process

④ Bright wire coils

⑤ Twist process

⑥ EHS WIRE Galvanized steel Wire Rope

Galvanized Steel Strand Breaking Force

Things to note when choosing High-strength wire rope

1. Strength grade: Select the appropriate strength grade according to the application requirements to ensure safety and performance.

2. Galvanizing layer quality: Ensure that the galvanizing layer is uniform and defect-free to provide the best corrosion protection.

3. Size and structure: Select the appropriate wire rope diameter and structure according to the specific application.

4. Use environment: Consider the corrosiveness and working conditions of the use environment and select a wire rope that adapts to these environments.

5. Regular inspection and maintenance: Regularly check the wear and corrosion of the wire rope and replace the damaged wire rope in time to ensure safety.

Product Section view

Galvanized Steel Strand

Galvanized steel strand is a steel product made bytwisting multiple galvanized steel wires. The galvanizedlayer can effectively prevent corrosion of steel strands inharsh environments and extend their service life. Due toits high strength, corrosion resistance, and good stability,it is widely used in fields such as power, communication,agriculture, construction, and engineering.Such as messenger wire, guy wire, trength member, andcan also be used as grounding wires for overhead powertransmission, barrier cable on sides of highways, or structurecable in building.

Galvanized Steel Strand Optical Fiber Cable

Galvanized steel strand is specially designed as a strength member for optical fiber cables. It is made of high-quality carbon steel wires that are uniformly galvanized to provide excellent corrosion resistance and long service life. With smooth surface, tight stranding, and high tensile strength, the strand ensures stable mechanical performance and reliable support for overhead optical fiber cables. It is widely used in telecommunication, power transmission lines, and other aerial cable applications.

GJ Type Galvanized Steel Strand

GJ type galvanized steel strand is mainly used as a supporting and reinforcing core for optical fiber cables. It is manufactured from high-strength carbon steel wires that are hot-dip galvanized to ensure excellent corrosion resistance, uniform coating, and long-term durability. With precise stranding, smooth surface, and stable tensile performance, GJ type galvanized steel strand provides reliable mechanical support for aerial optical fiber cables, power transmission lines, and telecommunication projects.

Galvanized steel Strand Structure

Galvanized Steel Strand Display

Galvanized steel Wire Rope Application

EHS (Extra High Strength) galvanized steel wire rope is widely used in construction, marine engineering, mining, power communication, industrial manufacturing, agriculture, entertainment facilities, transportation and logistics due to its high strength and corrosion resistance. It provides reliable support in lifting equipment, bridge cables, mooring systems, mine hoisting, cable support, fence construction, cable car zip lines and cargo lashing, ensuring safety and stability. Regular inspection and proper maintenance are the key to ensure its long service life and performance.

PC Steel Strand

PC steel strand is a steel cable made up of multiplehigh-strength steel wires twisted together. After stress relieftreatment, it is used in prestressed concrete structures toenhance bearing capacity and reduce deformation.It is usually made up of 2, 3, 7 or 19 steel wires twisted together.and the surface can be treated with anti-corrosion such asgalvanizing and epoxy resin coating, forming a compactcross-section through spiral twisting. The main characteristicsare high strength and good relaxation performance, and it is alsorelatively straight when unfolded. The common tensile strengthgrade is 1860 MPa. Mainly used for large-span structures such asbridges, buildings, and water conservancy, it enhances thecompressive performance of concrete through prestressingtechnology and is commonly used in post tensioning construction.

PC Steel Strand Standards

Our company can manufacture according to customer requirements and international standards, including Chinese Standard GB/T 5224-2014, American Standard ASTM A416, British Standard BS5896, and Japanese Standard JIS G3536. Detailed specifications are as follows:

EHS WIRE Galvanized steel Wire Rope Feature

EHS (Extra High Strength) Galvanized Steel Wire Rope is known for its superior strength and durability, making it ideal for demanding applications. Here are some key features:

1.High Tensile Strength: EHS wire rope is designed to withstand high loads, providing excellent performance in heavy-duty applications such as construction, lifting, and rigging.

2.Corrosion Resistance: The galvanization process coats the steel wire with a layer of zinc, which provides significant resistance to corrosion and rust. This makes it suitable for use in harsh environments, including marine and industrial settings.

3.Durability: The combination of high strength and corrosion resistance results in a highly durable wire rope that can endure frequent use and exposure to the elements without significant wear and tear.

4.Flexibility: Despite its high strength, EHS wire rope maintains a degree of flexibility, which allows it to be used in applications requiring bending and coiling.

5.Abrasion Resistance: The galvanized coating not only protects against corrosion but also adds a layer of abrasion resistance, further extending the wire rope’s lifespan.

6.Safety: EHS wire ropes are designed to meet stringent safety standards, ensuring reliable performance in critical applications such as cranes, elevators, and safety harnesses.

7.Versatility: Available in various diameters and configurations (e.g., different strand and core constructions), EHS galvanized steel wire rope can be customized to meet specific needs and applications.

8.Cost-Effectiveness: While it may be more expensive upfront compared to non-galvanized wire rope, the extended lifespan and reduced maintenance costs make EHS galvanized wire rope a cost-effective solution in the long run.

EHS WIRE Galvanized steel Wire Rope Testing Equipment

The inspection items for galvanized steel strands include appearance inspection, dimensional measurement, galvanized layer thickness measurement, mechanical performance tests (tensile strength, yield strength, elongation), fatigue testing, corrosion testing, relaxation testing, torsion testing, and zinc coating mass determination. These inspections ensure the quality and performance of galvanized steel strands, guaranteeing their safety and reliability in use.

Why Choose us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS, TUV, BV 3.2 report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.

Galvanized Steel Wire Rope Packing:

1. The weight of each package is 300KG-310KG. The packaging is usually in the form of shafts, discs, etc., and can be packed with moisture-proof paper, linen and other materials.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,