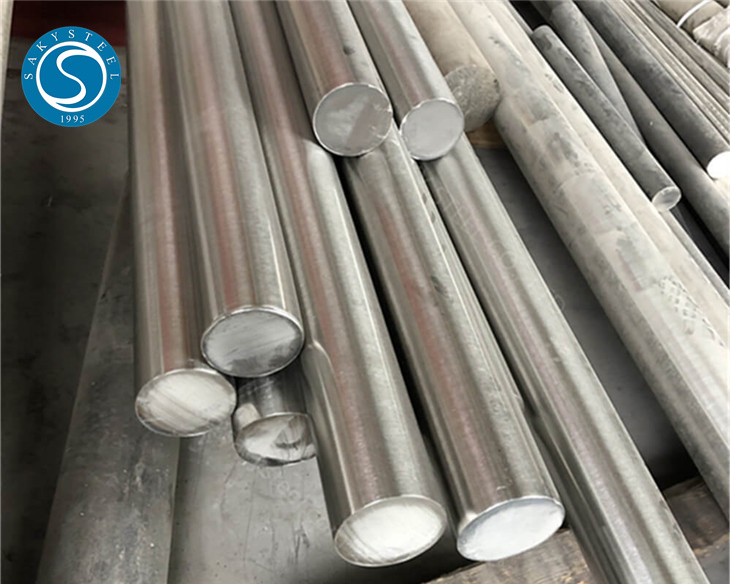

Custom S45000 450 Stainless Steel Bar

Short Description:

Custom 450 Bar (UNS S45000) offers excellent corrosion resistance and high strength. Ideal for aerospace, industrial, and marine applications.

Custom 450 Bars:

Custom 450 Bars are high-strength, martensitic stainless steel alloys known for their excellent corrosion resistance and moderate toughness. They offer a unique combination of strength and corrosion resistance, making them ideal for demanding applications in aerospace, chemical processing, and marine environments. Custom 450 Bars can be heat treated to achieve various mechanical properties and are well-suited for applications requiring high performance in harsh conditions. With their ease of fabrication and reliable performance, these bars are widely used in structural components, fasteners, and other critical parts.

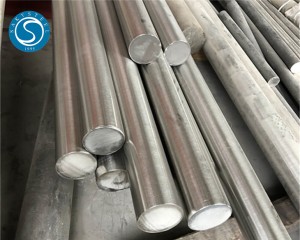

Specifications Of Custom 450 Stainless Steel Bar:

| Grade | 450,455,465,etc. |

| Standard | ASTM A564 |

| Surface | Bright, Polish & Black |

| Condition | Polished, Hot Rolled Pickled, Hairline, Sand BlastingFinished, Cold Drawn |

| Length | 1 to 12 Meters |

| Type | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

| Mill Test Certificate | EN 10204 3.1 or EN 10204 3.2 |

AMS 5773 Custom 450 Bars Equivalent Grades:

| STANDARD | UNS | Miscellaneous |

| Custom 450 | S45000 | XM-25 |

UNS S45000 Custom 450 Bars Chemical Composition:

| Grade | C | Mn | P | S | Si | Cr | Ni | Mo | Co |

| S45000 | 0.05 | 1.0 | 0.03 | 0.03 | 1.0 | 14.0-16.0 | 5.0-7.0 | 0.5-1.0 | 1.25-1.75 |

Mechanical Properties of Custom S45000 Round Bars

| Element | Density | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Custom 450 | 7.8 g/cm3 | Psi – 143000, MPa – 986 | Psi – 118000, MPa – 814 | 13.30 % |

Custom 450 Bars Application

Custom 450 Bars are widely used in industries that require high strength, corrosion resistance, and reliable performance under demanding conditions.

1.Aerospace: Structural components, fasteners, and other critical parts in aircraft that require high strength and durability.

2.Marine: Components exposed to saltwater environments, such as shafts, valves, and pumps, due to the alloy's excellent corrosion resistance.

3.Chemical Processing: Equipment and parts like tanks, fittings, and fasteners used in chemical plants, where resistance to corrosive substances is crucial.

4.Energy and Power Generation: Used in turbines, heat exchangers, and other equipment that operates in high-temperature or high-stress conditions.

5.Medical Devices: Custom 450 Bars are sometimes used in surgical instruments and medical equipment due to their combination of strength and corrosion resistance.

6.Oil & Gas: Components like valves and shafts in offshore and onshore drilling equipment, where exposure to harsh environments requires robust materials.

Why Choose us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS TUV report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.

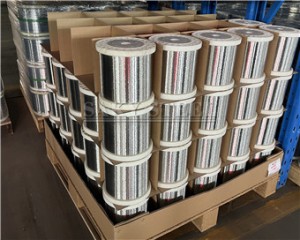

Custom 450 Stainless Bar Packing:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,