Competitive Price for Scrap Iron Cutting Machine - Stainless Steel T Section – Saky Steel

Competitive Price for Scrap Iron Cutting Machine - Stainless Steel T Section – Saky Steel Detail:

Stainless steel T bar,T section or Tee profile with grade 201,303,304,304L,316,316L,316TI,321,310S,410,430

Specifications of Stainless steel T bar:

| Standard | ASTM A276, A484, A479, A580, A582, JIS G4303, JIS G4311,DIN 1654-5,DIN 17440,KS D3706,GB/T 1220 |

| Material | 201,202,205,XM-19 etc. 301,303,304,304L,304H,309S,310S,314,316,316L,316Ti,317,321,321H,329,330,348 etc. 409,410,416,420,430,430F,431,440 2205,2507,S31803,2209,630,631,15-5PH,17-4PH,17-7PH,904L,F51,F55,253MA etc. |

| Surface | Bright,Polishing,Pickled,Peeled,Black,Grinding,Mill,Mirror,Hairline etc |

| Technology | Cold Drawn,Hot Rolled,Forged |

| Specifications | as required |

| Tolerance | H9, H11, H13, K9, K11, K13 or as required |

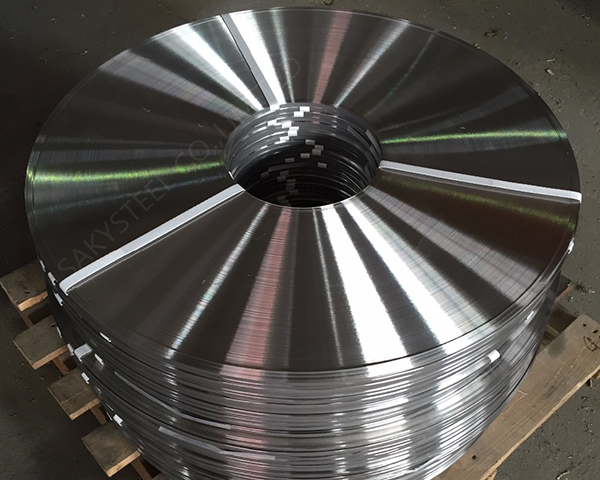

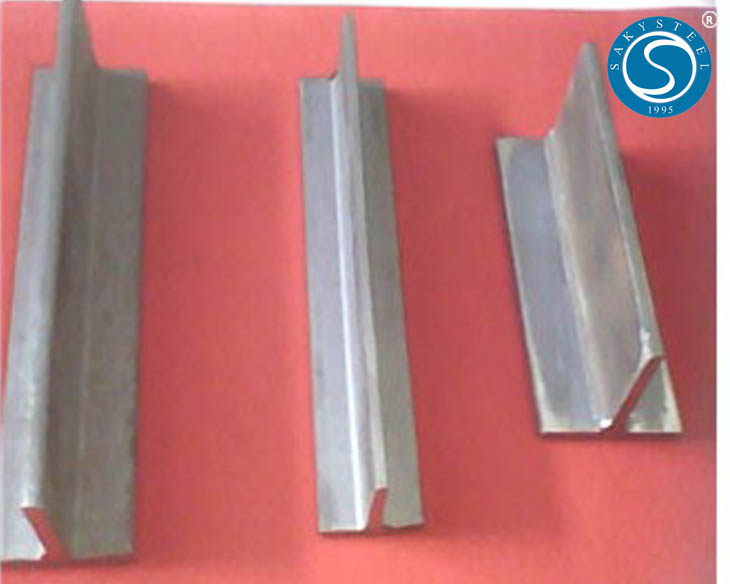

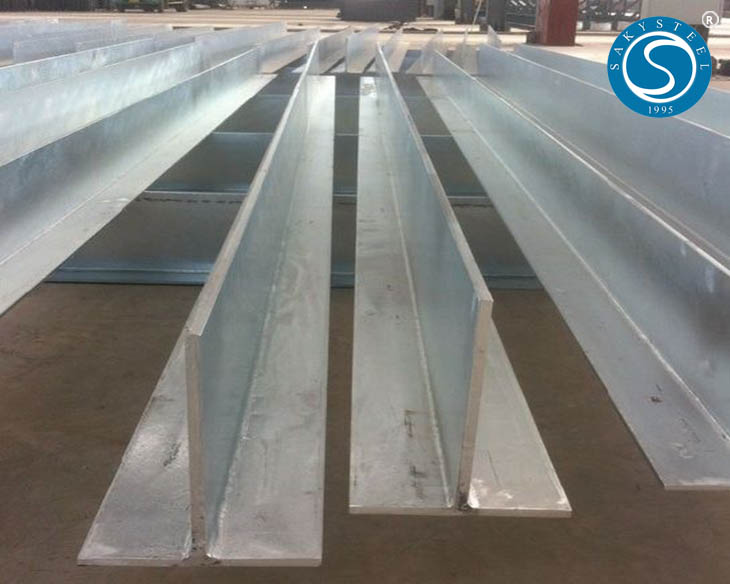

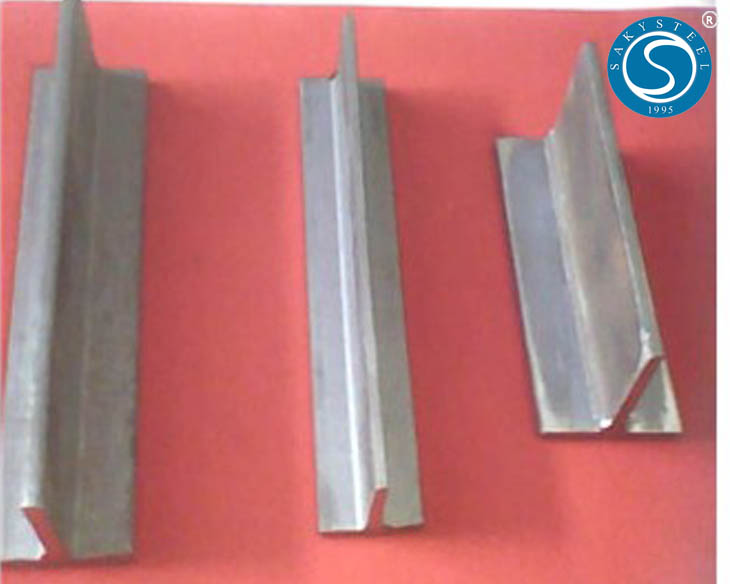

Stainless Steel T Section products from Sakysteel:

Stainless Steel T Section manufacturers Stainless Steel T Section manufacturers |

Stainless Steel T Section suppliers Stainless Steel T Section suppliers |

Weight of Stainless steel T bar

| Model | Weight | Model | Weight |

| 100*50*5*7 | 9.54 | 344*354*16*16 | 131 |

| 100*100*6*8 | 17.2 | 346*174*6*9 | 41.8 |

| 125*60*6*8 | 13.3 | 350*175*7*11 | 50 |

| 125*125*6.5*9 | 23.8 | 344*348*10*16 | 115 |

| 148*100*6*9 | 21.4 | 350*350*12*19 | 137 |

| 150*75*5*7 | 14.3 | 388*402*15*15 | 141 |

| 150*150*7*10 | 31.9 | 390*300*10*16 | 107 |

| 175*90*5*8 | 18.2 | 394*398*11*18 | 147 |

| 175*175*7.5*11 | 40.3 | 400*150*8*13 | 55.8 |

| 194*150*6*9 | 31.2 | 396*199*7*11 | 56.7 |

| 198*99*4.5*7 | 18.5 | 400*200*8*13 | 66 |

| 200*100*5.5*8 | 21.7 | 400*400*13*21 | 172 |

| 200*200*8*12 | 50.5 | 400*408*21*21 | 197 |

| 200*204*12*12 | 72.28 | 414*405*18*28 | 233 |

| 244*175*7*11 | 44.1 | 440*300*11*18 | 124 |

| 244*252*11*11 | 64.4 | 446*199*7*11 | 66.7 |

| 248*124*5*8 | 25.8 | 450*200*9-14 | 76.5 |

| 250*125*6*9 | 29.7 | 482*300*11*15 | 115 |

| 250*250*9*14 | 72.4 | 488*300*11*18 | 129 |

| 250*255*14*14 | 82.2 | 496*199*9*14 | 79.5 |

| 294*200*8*12 | 57.3 | 500*200*10*16 | 89.6 |

| 300*150*6.5*9 | 37.3 | 582*300*12*17 | 137 |

| 294*302*12*12 | 85 | 588*300*12*20 | 151 |

| 300*300*10*15 | 94.5 | 596*199*10*15 | 95.1 |

| 300*305*15*15 | 106 | 600*200*11*17 | 106 |

| 338*351*13*13 | 106 | 700*300*13*24 | 185 |

| 340*250*9*14 | 79.7 |

More grade of Stainless steel T bar

<td

| Type | Grade | Grade | Chemical Component % | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Other | |||

| Austenitic stainless steel | 201 | 1Cr17Mn6Ni5N | =0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | =0.060 | =0.030 | - | =1.00 | - | =0.25 | - |

| 201L | 03Cr17Mn6Ni5N | =0.030 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | =0.060 | =0.030 | =1.00 | =0.25 | ||||

| 202 | 1Cr18Mn8Ni5N | =0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | =0.060 | =0.030 | =1.00 | - | =0.25 | - | ||

| 204 | 03Cr16Mn8Ni2N | =0.030 | 15.00-17.00 | 1.50-3.50 | 7.00-9.00 | 0.15-0.30 | |||||||

| 1Cr18Mn10Ni5Mo3N | =0.10 | 17.00-19.00 | 4.00-6.00 | 8.50-12.00 | 2.80-3.50 | 0.20-0.30 | |||||||

| 2Cr13Mn9Ni4 | 0.15-0.25 | 12.00-14.00 | 3.70-5.00 | 8.00-10.00 | |||||||||

| 2Cr15Mn15Ni2N | 0.15-0.25 | 14.00-16.00 | 1.50-3.00 | 14.00-16.00 | 0.15-0.30 | ||||||||

| 1Cr18Mn10Ni5Mo3N | =0.15 | 17.00-19.00 | 4.00-6.00 | 8.50-12.00 | =0.060 | =0.030 | 2.8-3.5 | =1.00 | - | 0.20-0.30 | - | ||

| 301 | 1Cr17Ni7 | =0.15 | 16.00-18.00 | 6.00-8.00 | =2.00 | =0.065 | =0.030 | - | =1.00 | - | - | - | |

| 302 | 1Cr18Ni9 | =0.15 | 17.00-19.00 | 8.00-10.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 303 | Y1Cr18Ni9 | =0.15 | 17.00-19.00 | 8.00-10.00 | =2.00 | =0.20 | =0.030 | 1) | =1.00 | - | - | - | |

| 303se | Y1Cr18Ni9Se | =0.15 | 17.00-19.00 | 8.00-10.00 | =2.00 | =0.20 | =0.030 | - | =1.00 | - | - | Se=0.15 | |

| 304 | 0Cr18Ni9 | =0.07 | 17.00-19.00 | 8.00-10.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 304L | 00Cr19Ni10 | =0.030 | 18.00-20.00 | 8.00-10.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 304N1 | 0Cr19Ni9N | =0.08 | 18.00-20.00 | 7.00-10.50 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | 0.10-0.25 | - | |

| 304N2 | 0Cr18Ni10NbN | =0.08 | 18.00-20.00 | 7.50-10.50 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | 0.15-0.30 | Nb=0.15 | |

| 304LN | 00Cr18Ni10N | =0.030 | 17.00-19.00 | 8.50-11.50 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | 0.12-0.22 | - | |

| 305 | 1Cr18Ni12 | =0.12 | 17.00-19.00 | 10.50-13.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 309S | 0Cr23Ni13 | =0.08 | 22.00-24.00 | 12.00-15.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 310S | 0Cr25Ni20 | =0.08 | 24.00-26.00 | 19.00-22.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 316 | 0Cr17Ni12Mo2 | =0.08 | 16.00-18.50 | 10.00-14.00 | =2.00 | =0.035 | =0.030 | 2.00-3.00 | =1.00 | - | - | - | |

| 1Cr18Ni12Mo2Ti6) | =0.12 | 16.00-19.00 | 11.00-14.00 | =2.00 | =0.035 | =0.030 | 1.80-2.50 | =1.00 | - | - | Ti5(C%-0.02)~0.08 | ||

| 0Cr18Ni12Mo2Ti | =0.08 | 16.00-19.00 | 11.00-14.00 | =2.00 | =0.035 | =0.030 | 1.80-2.50 | =1.00 | - | - | Ti5*C%-0.70 | ||

| 316L | 00Cr17Ni14Mo2 | =0.030 | 16.00-18.00 | 12.00-15.00 | =2.00 | =0.035 | =0.030 | 2.00-3.00 | =1.00 | - | - | - | |

| 316N | 0Cr17Ni12Mo2N | =0.08 | 16.00-18.00 | 10.00-14.00 | =2.00 | =0.035 | =0.030 | 2.00-3.00 | =1.00 | - | 0.10-0.22 | - | |

| 316N | 00Cr17Ni13Mo2N | =0.030 | 16.00-18.50 | 10.50-14.50 | =2.00 | =0.035 | =0.030 | 2.00-3.00 | =1.00 | - | 0.12-0.22 | - | |

| 316J1 | 0Cr18Ni12Mo2Cu2 | =0.08 | 17.00-19.00 | 10.00-14.50 | =2.00 | =0.035 | =0.030 | 1.20-2.75 | =1.00 | 1.00-2.50 | - | - | |

| 316J1L | 00Cr18Ni14Mo2Cu2 | =0.030 | 17.00-19.00 | 12.00-16.00 | =2.00 | =0.035 | =0.030 | 1.20-2.75 | =1.00 | 1.00-2.50 | - | - | |

| 317 | 0Cr19Ni13Mo3 | =0.12 | 18.00-20.00 | 11.00-15.00 | =2.00 | =0.035 | =0.030 | 3.00-4.00 | =1.00 | - | - | - | |

| 317L | 00Cr19Ni13Mo3 | =0.08 | 18.00-20.00 | 11.00-15.00 | =2.00 | =0.035 | =0.030 | 3.00-4.00 | =1.00 | - | - | - | |

| 1Cr18Ni12Mo3Ti6 | =0.12 | 16.00-19.00 | 11.00-14.00 | =2.00 | =0.035 | =0.030 | 2.50-3.50 | =1.00 | - | - | Ti5(C%-0.02)~0.08 | ||

| 0Cr18Ni12Mo3Ti | =0.08 | 16.00-19.00 | 11.00-14.00 | =2.00 | =0.035 | =0.030 | 2.50-3.50 | =1.00 | - | - | Ti5*C%-0.70 | ||

| 317J1 | 0Cr18Ni16Mo5 | =0.040 | 16.00-19.00 | 15.00-17.00 | =2.00 | =0.035 | =0.030 | 4.00-6.00 | =1.00 | - | - | - | |

| 321 | 1Cr18Ni9Ti6 | =0.12 | 17.00-19.00 | 8.00-11.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | Ti5(C%-0.02)~0.08 | |

| 0Cr18Ni10Ti | =0.08 | 17.00-19.00 | 9.00-12.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | Ti=5*C% | ||

| 347 | 0Cr18Ni11Nb | =0.08 | 17.00-19.00 | 9.00-13.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | Nb=10*C% | |

| XM7 | 0Cr18Ni9Cu3 | =0.08 | 17.00-19.00 | 8.50-10.50 | =2.00 | =0.035 | =0.030 | - | =1.00 | 3.00-4.00 | - | - | |

| XM15J1 | 0Cr18Ni13Si4 | =0.08 | 15.00-20.00 | 11.50-15.00 | =2.00 | =0.035 | =0.030 | - | 3.00-5.00 | - | - | 2) | |

| Austenite | 329J1 | 0Cr26Ni5Mo2 | =0.08 | 23.00-28.00 | 3.00-6.00 | =1.50 | =0.035 | =0.030 | 1.00-3.00 | =1.00 | - | - | 2) |

| | | 1Cr18Ni11Si4AlTi | 0.10-0.18 | 17.50-19.50 | 10.–120.. | =0.80 | =0.035 | =0.030 | - | 3.40-4.00 | - | - | Al 0.10-0.30; Ti 0.40-0.70 | |

| Ferrite Stainless Steel | 00Cr18Ni5MoSi2 | =0.030 | 18.00-19.50 | 4.50-5.50 | 1.00-2.00 | =0.035 | =0.030 | 2.50-3.00 | 1.30-2.00 | - | - | - | |

| Ferrite Stainless Steel | 405 | 0Cr13Al | =0.08 | 11.50-14.50 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | Al 0.10-0.30 |

| 410L | 00Cr12 | =0.030 | 11.00-13.00 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 430 | 1Cr17 | =0.12 | 16.00-18.00 | 3) | =1.25 | =0.035 | =0.030 | - | =0.75 | - | - | - | |

| 430F | Y1Cr17 | =0.12 | 16.00-18.00 | 3) | =1.00 | =0.035 | =0.15 | 1) | =1.00 | - | - | - | |

| 434 | 1Cr17Mo | =0.12 | 16.00-18.00 | 3) | =1.00 | =0.035 | =0.030 | 0.75-1.25 | =1.00 | - | - | - | |

| 447J1 | 00Cr30Mo2 | =0.010 | 28.50-32.00 | - | =0.40 | =0.035 | =0.030 | 1.50-2.50 | =0.40 | - | =0.015 | - | |

| XM27 | 00Cr27Mo | =0.010 | 25.00-27.50 | - | =0.40 | =0.035 | =0.030 | 0.75-1.50 | =0.40 | - | =0.015 | - | |

| Martensite stainless steel | 403 | 1Cr12 | =0.15 | 11.50-13.00 | 3) | =1.00 | =0.035 | =0.030 | - | =0.50 | - | - | - |

| 410 | 1Cr13 | =0.15 | 11.50-13.50 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 405 | 0Cr13 | =0.08 | 11.50-13.50 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 416 | Y1Cr13 | =0.15 | 12.00-14.00 | 3) | =1.25 | =0.035 | =0.15 | 1) | =1.00 | - | - | - | |

| 410J1 | 1Cr13Mo | =0.08-0.18 | 11.50-14.00 | 3) | =1.00 | =0.035 | =0.030 | 0.30-0.60 | =0.60 | - | - | - | |

| 420J1 | 2Cr13 | 0.16-0.25 | 12.00-14.00 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 420J2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 420F | Y3Cr13 | 0.26-0.40 | 12.00-14.00 | 3) | =1.25 | =0.035 | =0.15 | 1) | =1.00 | - | - | - | |

| 3Cr13Mo | 0.28-0.35 | 12.00-14.00 | 3) | =1.00 | =0.035 | =0.030 | 0.50-1.00 | =0.80 | - | - | - | ||

| 4Cr13 | 0.36-0.45 | 12.00-14.00 | 3) | =0.80 | =0.035 | =0.030 | - | =0.60 | - | - | - | ||

| 431 | 1Cr17Ni2 | 0.11-0.17 | 16.00-18.00 | 1.50-2.50 | =0.80 | =0.035 | =0.030 | - | =0.80 | - | - | - | |

| 440A | 7Cr17 | 0.60-0.75 | 16.00-18.00 | 3) | =1.00 | =0.035 | =0.030 | 4) | =1.00 | - | - | - | |

| 440B | 8Cr17 | 0.75-0.95 | 16.00-18.00 | 3) | =1.00 | =0.035 | =0.030 | 4) | =1.00 | - | - | - | |

| 9Cr18 | 0.90-1.00 | 17.00-19.00 | 3) | =0.80 | =0.035 | =0.030 | 4) | =0.80 | - | - | - | ||

| 440C | 11Cr17 | 0.95-1.20 | 16.00-18.00 | 3) | =1.00 | =0.035 | =0.030 | 4) | =1.00 | - | - | - | |

| 440F | Y11Cr17 | 0.95-1.20 | 16.00-18.00 | 3) | =1.25 | =0.035 | =0.15 | 4) | =1.00 | - | - | - | |

| 9Cr18Mo | 0.95-1.10 | 16.00-18.00 | 3) | =0.80 | =0.035 | =0.030 | 0.40-0.70 | =0.80 | - | - | - | ||

| 9Cr18MoV | 0.85-0.95 | 17.00-19.00 | 3) | =0.80 | =0.035 | =0.030 | 1.00-1.30 | =0.80 | - | - | V0.07-0.12 | ||

| PH Stainless Steel | 630 | 0Cr17Ni4Cu4Nb | =0.07 | 15.50-17.50 | 6.50-7.50 | =1.00 | =0.035 | =0.030 | - | =1.00 | 3.00-5.00 | - | Nb 0.15-0.45 |

| 631 | 0Cr17Ni7Al | =0.09 | 16.00-18.00 | 6.50-7.50 | =1.00 | =0.035 | =0.030 | - | =1.00 | =0.50 | - | Al 0.75-1.50 | |

Product detail pictures:

Related Product Guide:

How to Save Time and Cost With a 316 Stainless Steel Bar

Stainless Steel in Modern Pubs and Bars

We aim to find out quality disfigurement from the production and supply the best service to domestic and overseas customers wholeheartedly for Competitive Price for Scrap Iron Cutting Machine - Stainless Steel T Section – Saky Steel, The product will supply to all over the world, such as: Jordan , Belgium , Egypt , After 13 years of researching and developing products, our brand can represent wide range of products with outstanding quality in world market. We have completed big contracts from many countries such as Germany, Israel, Ukraine, United Kingdom, Italy, Argentina, France, Brazil, and so on. You probably feel secure and satisfy when copperate with us.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.