Chinese wholesale Stainless Steel Flexible Braided Tubes - Stainless Steel Flange – Saky Steel

Chinese wholesale Stainless Steel Flexible Braided Tubes - Stainless Steel Flange – Saky Steel Detail:

304 stainless steel flange

| Grade | C% | Si% | Mn% | P% | S% | Cr% | Ni% | Mo% | Cu% |

| 304 | =0.08 | =1.0 | =2.0 | =0.045 | =0.03 | 18.0-20.0 | 8.0-10.0 | - | – |

| T*S | Y*S | Hardness | Elongation | |

| (Mpa) | (Mpa) | HRB | HB | (%) |

| =520 | =205 | – | – | =40 |

Specifications of stainless steel flange

| 1 | Material: | Stainless Steel:such as 304,304L,316,316L,321 ,310S,904L,S31803,F51and so on. |

| 2 | Standard: | GB,JIS,BS,DIN.ANSI and Non standard, |

| 3 | ANSI Class: | 150.300.400.600.900.1500.3000 |

| 4 | Size: | 1/2′-60′ |

| 5 | Type: | Slip-on flanges, Blind flanges, Lap joint flanges, Welding neck flanges,Plate flange,Socket welding flanges and Treaded flanges |

| 6 | Pressure ratings: | class:150 300 400 600 900 1500 and 2500, pn :6 10 16 25 40 64 and 160 ,5K-40K and so on for stainless steel Blind flange |

| 7 | Sealing surface: | FF ,RF, LJ, FM ,R.T.J ,R.J and so on . |

| 8 | Production process: | raw material–cutting–heating–forging–heat treatment–maching–inspection. |

| 9 | Mill ceitificate: | 3.1B |

| 10 | Certificates: | IS09001:2008and CE |

| 11 | manufature license: | manufacture license of special equipment of P.R.C |

| 12 | Marking: | according to client’s requirement. |

| 13 | QC staff : | 10-15 . |

| 14 | Inspection: | in-house and the third party. |

| 15 | Application: | petroleum,chemical,power,gas,water,linepipe, heat exchanger,shipbuilding,construction,etc. |

| 16 | Tolerance: | not less than +_8% of normal wall thickness. |

| 17 | Our objective: | Survival by quality and development by credibility. |

| Size | 1/2′ ‘ (DN15) to 48′ ‘ (DN1200) |

| Standard | ANSI, API, DIN, GOST, BS, AS, JIS, JPI |

| Material | Carbon Steel: A105(N) C22.8 ST-37.2 S400 S440 SQ235(CS20#) A106B A53 Q345Stainless Steel: 304, 304L, 316, 316L, A350 LF2, 321, 347, 347H Alloy Steel: ASTM A182 F1, F5a, F9, F11, F12, F22, F91 |

| Pressure | Class150, 300, 600, 900 1500 and 2500 PN6, PN10, PN16, PN25, PN40 and PN64 JIS 5K, 10K, 16K and 20K |

| Type | Slip-On, Welding Neck, Blind, Socket Welding, Threaded, Lap Joint , Plate, etc |

| Facing | RF, FF, FM-M, T-G, RJ, etc. |

| Finish | Transparent oil, rust-proof oil, hot galvanizing |

| Connection | Butt Weld & Socket Weld & Thread |

| Marking | standard or as customer’ s need |

| Inspection | in-house or the third party |

| Application | chemical industry, petroleum industry, construction industry, and so on |

| Delivery Time | usually within 25-30 days after we have confirmed your order |

| MOQ | 10 pieces |

| Packing | wooden cases or wooden pallets or as per customer’ s requirement |

| Productivity | 300000 tons per year |

More grades of stainless steel flange

| Type | Grade | Grade | Chemical Component % | ||||

| Austenitic stainless steel | C | Cr | Ni | Mn | |||

| 201 | 1Cr17Mn6Ni5N | 0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ||

| 201L | 03Cr17Mn6Ni5N | 0.030 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ||

| 202 | 1Cr18Mn8Ni5N | 0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ||

| 204 | 03Cr16Mn8Ni2N | 0.030 | 15.00-17.00 | 1.50-3.50 | 7.00-9.00 | ||

| 1Cr18Mn10Ni5Mo3N | 0.10 | 17.00-19.00 | 4.00-6.00 | 8.50-12.00 | |||

| 2Cr13Mn9Ni4 | 0.15-0.25 | 12.00-14.00 | 3.70-5.00 | 8.00-10.00 | |||

| 2Cr15Mn15Ni2N | 0.15-0.25 | 14.00-16.00 | 1.50-3.00 | 14.00-16.00 | |||

| 1Cr18Mn10Ni5Mo3N | 0.15 | 17.00-19.00 | 4.00-6.00 | 8.50-12.00 | |||

| 301 | 1Cr17Ni7 | 0.15 | 16.00-18.00 | 6.00-8.00 | 2.00 | ||

| 302 | 1Cr18Ni9 | 0.15 | 17.00-19.00 | 8.00-10.00 | 2.00 | ||

| 303 | Y1Cr18Ni9 | 0.15 | 17.00-19.00 | 8.00-10.00 | 2.00 | ||

| 303se | Y1Cr18Ni9Se | 0.15 | 17.00-19.00 | 8.00-10.00 | 2.00 | ||

| 304 | 0Cr18Ni9 | 0.07 | 17.00-19.00 | 8.00-10.00 | 2.00 | ||

| 304L | 00Cr19Ni10 | 0.030 | 18.00-20.00 | 8.00-10.00 | 2.00 | ||

| 304N1 | 0Cr19Ni9N | 0.08 | 18.00-20.00 | 7.00-10.50 | 2.00 | ||

| 304N2 | 0Cr18Ni10NbN | 0.08 | 18.00-20.00 | 7.50-10.50 | 2.00 | ||

| 304LN | 00Cr18Ni10N | 0.030 | 17.00-19.00 | 8.50-11.50 | 2.00 | ||

| 305 | 1Cr18Ni12 | 0.12 | 17.00-19.00 | 10.50-13.00 | 2.00 | ||

| 309S | 0Cr23Ni13 | 0.08 | 22.00-24.00 | 12.00-15.00 | 2.00 | ||

| 310S | 0Cr25Ni20 | 0.08 | 24.00-26.00 | 19.00-22.00 | 2.00 | ||

| 316 | 0Cr17Ni12Mo2 | 0.08 | 16.00-18.50 | 10.00-14.00 | 2.00 | ||

| 1Cr18Ni12Mo2Ti6) | 0.12 | 16.00-19.00 | 11.00-14.00 | 2.00 | |||

| 0Cr18Ni12Mo2Ti | 0.08 | 16.00-19.00 | 11.00-14.00 | 2.00 | |||

| 316L | 00Cr17Ni14Mo2 | 0.030 | 16.00-18.00 | 12.00-15.00 | 2.00 | ||

| 316N | 0Cr17Ni12Mo2N | 0.08 | 16.00-18.00 | 10.00-14.00 | 2.00 | ||

| 316N | 00Cr17Ni13Mo2N | 0.030 | 16.00-18.50 | 10.50-14.50 | 2.00 | ||

| 316J1 | 0Cr18Ni12Mo2Cu2 | 0.08 | 17.00-19.00 | 10.00-14.50 | 2.00 | ||

| 316J1L | 00Cr18Ni14Mo2Cu2 | 0.030 | 17.00-19.00 | 12.00-16.00 | 2.00 | ||

| 317 | 0Cr19Ni13Mo3 | 0.12 | 18.00-20.00 | 11.00-15.00 | 2.00 | ||

| 317L | 00Cr19Ni13Mo3 | 0.08 | 18.00-20.00 | 11.00-15.00 | 2.00 | ||

| 1Cr18Ni12Mo3Ti6 | 0.12 | 16.00-19.00 | 11.00-14.00 | 2.00 | |||

| 0Cr18Ni12Mo3Ti | 0.08 | 16.00-19.00 | 11.00-14.00 | 2.00 | |||

| 317J1 | 0Cr18Ni16Mo5 | 0.040 | 16.00-19.00 | 15.00-17.00 | 2.00 | ||

| 321 | 1Cr18Ni9Ti6 | 0.12 | 17.00-19.00 | 8.00-11.00 | 2.00 | ||

| 0Cr18Ni10Ti | 0.08 | 17.00-19.00 | 9.00-12.00 | 2.00 | |||

| 347 | 0Cr18Ni11Nb | 0.08 | 17.00-19.00 | 9.00-13.00 | 2.00 | ||

| XM7 | 0Cr18Ni9Cu3 | 0.08 | 17.00-19.00 | 8.50-10.50 | 2.00 | ||

| XM15J1 | 0Cr18Ni13Si4 | 0.08 | 15.00-20.00 | 11.50-15.00 | 2.00 | ||

| Austenite Ferrite Stainless Steel |

329J1 | 0Cr26Ni5Mo2 | =0.08 | 23.00-28.00 | 3.00-6.00 | =1.50 | =0.035 | =0.030 | 1.00-3.00 | =1.00 | - | - | 2) |

| 1Cr18Ni11Si4AlTi | 0.10-0.18 | 17.50-19.50 | 10.–120.. | =0.80 | =0.035 | =0.030 | - | 3.40-4.00 | - | - | Al 0.10-0.30; Ti 0.40-0.70 | ||

| 00Cr18Ni5MoSi2 | =0.030 | 18.00-19.50 | 4.50-5.50 | 1.00-2.00 | =0.035 | =0.030 | 2.50-3.00 | 1.30-2.00 | - | - | - | ||

| Ferrite Stainless Steel | 405 | 0Cr13Al | =0.08 | 11.50-14.50 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | Al 0.10-0.30 |

| 410L | 00Cr12 | =0.030 | 11.00-13.00 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 430 | 1Cr17 | =0.12 | 16.00-18.00 | 3) | =1.25 | =0.035 | =0.030 | - | =0.75 | - | - | - | |

| 430F | Y1Cr17 | =0.12 | 16.00-18.00 | 3) | =1.00 | =0.035 | =0.15 | 1) | =1.00 | - | - | - | |

| 434 | 1Cr17Mo | =0.12 | 16.00-18.00 | 3) | =1.00 | =0.035 | =0.030 | 0.75-1.25 | =1.00 | - | - | - | |

| 447J1 | 00Cr30Mo2 | =0.010 | 28.50-32.00 | - | =0.40 | =0.035 | =0.030 | 1.50-2.50 | =0.40 | - | =0.015 | - |

| XM27 | 00Cr27Mo | =0.010 | 25.00-27.50 | - | =0.40 | =0.035 | =0.030 | 0.75-1.50 | =0.40 | - | =0.015 | - | |

| Martensite stainless steel | 403 | 1Cr12 | =0.15 | 11.50-13.00 | 3) | =1.00 | =0.035 | =0.030 | - | =0.50 | - | - | - |

| 410 | 1Cr13 | =0.15 | 11.50-13.50 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 405 | 0Cr13 | =0.08 | 11.50-13.50 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 416 | Y1Cr13 | =0.15 | 12.00-14.00 | 3) | =1.25 | =0.035 | =0.15 | 1) | =1.00 | - | - | - | |

| 410J1 | 1Cr13Mo | =0.08-0.18 | 11.50-14.00 | 3) | =1.00 | =0.035 | =0.030 | 0.30-0.60 | =0.60 |

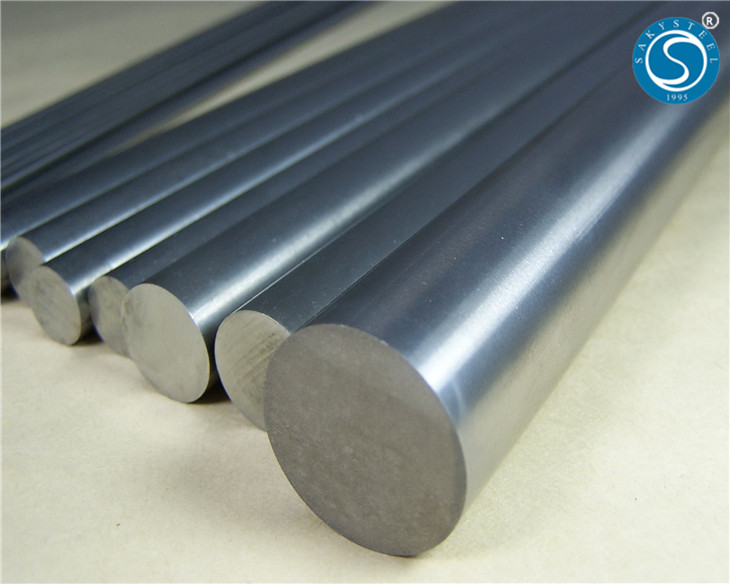

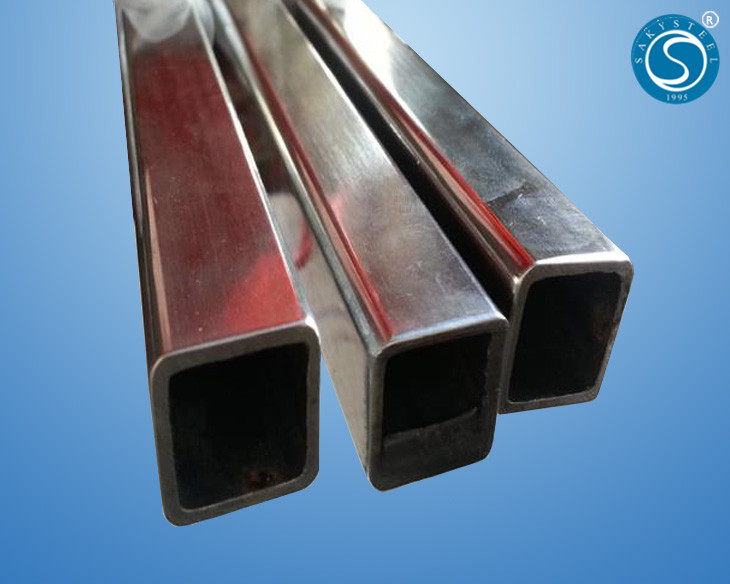

Product detail pictures:

Related Product Guide:

Stainless Steel Bars – Production, Importance, and Uses

How to Save Time and Cost With a 316 Stainless Steel Bar

We emphasize progress and introduce new solutions into the market each year for Chinese wholesale Stainless Steel Flexible Braided Tubes - Stainless Steel Flange – Saky Steel, The product will supply to all over the world, such as: Somalia , Uruguay , Swiss , Our Company policy is "quality first, to be better and stronger, sustainable development" . Our pursuit goals is "for society, customers, employees, partners and enterprises to seek reasonable benefit". We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.

Write your message here and send it to us