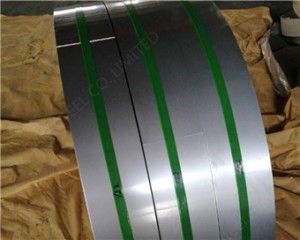

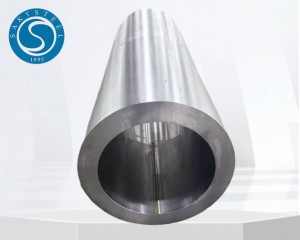

C67s CK67 C67 1.1231 CK68 XC68 70cr2 AISI 1065 Spring Steel Strips

Short Description:

| Specifications of Spring Steel Strip: |

| Grade | C67 ,XC68 |

| Standard | EN BS 10132-4 C67S 1.1231 |

| Thickness | 0.10 – 5.0mm |

| Width | 10 – 600mm |

| Form | Steel Coils Strips |

| Hardness | soft, 1/4H, 1/2H, FH etc. |

| CHEMICAL COMPOSITION OF Stainless Spring Steel Strip: |

| Grade | C | Mn | Si | S | Cu | Ni | Cr | Mo | P |

| C67S | 0.65-0.73 | 0.6-0.9 | 0.15-0.35 | 0.025max | - | 0.4max | 0.4max | 0.1max | 0.025max |

| CK68 | 0.6-0.75 | 0.7max | 0.2-0.45 | 0.025max | - | - | - | - | 0.025max |

| 70cr2 | 0.65-0.70 | 0.75-0.90 | 0.2-0.30 | 0.030max | - | - | 0.55-0.70 | - | 0.030max |

| C67s Stainless Spring Steel Strip Mechanical Properties |

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

| C67s | 670-900 | 450-600 | 2%-10% |

| For quenched and tempered cold rolled strips, there are several possible surface finishes: |

The surface finish of annealed C67S 1.1231 steel strips after cold rolling and annealing in a controlled atmosphere is expected to be bright, resulting from the rolling and annealing processes.

1.Grey/Annealed Oxide Finish: This finish is unpolished and retains a natural grey appearance with an oxide layer.

2.Bright Tempered (Unpolished): In this case, the steel strip remains unpolished but exhibits a bright appearance due to the tempering process.

3.Polished Finish: This finish is achieved by employing processes like fine grinding or abrasive brushing to create a smooth and reflective surface.

4.Polished and Colored Finish: This finish involves heat treatment to create specific colors, such as annealed or yellow coloring, through oxidization processes.

| Why Choose Us: |

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. e guarantee to give a response within 24hours(usually in the same hour)

5. Provide SGS TUV report.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

7.Provide one-stop service

| SAKY STEEL’S Quality Assurance (including both Destructive and Non-Destructive) : |

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Impact analysis

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Roughness Testing

10. Metallography Experimental Test

| SAKY STEEL’S Packing: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky steel’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as