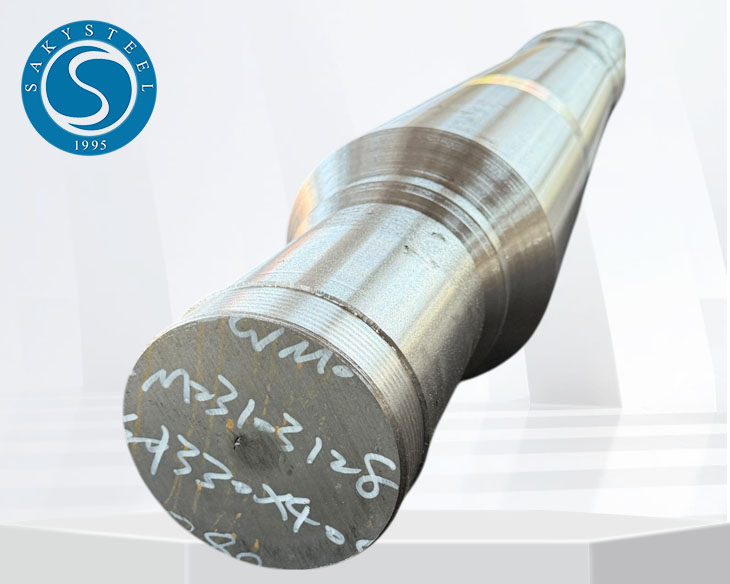

Bright Shaft Forgings

Short Description:

Explore durable, high-strength forged steel shafts for industrial and heavy machinery applications. Custom sizes available.

Forged Steel Shaft

Forged Steel Shaft is a high-strength mechanical component manufactured through the forging process, where steel is heated and shaped under extreme pressure to achieve superior durability and reliability. This process refines the grain structure of the material, enhancing its toughness, fatigue resistance, and load-bearing capacity. Forged steel shafts are widely used in industries such as automotive, aerospace, power generation, and heavy machinery, where performance under demanding conditions is critical. They can be customized in terms of size, shape, and material composition to meet specific industrial requirements, ensuring optimal performance and longevity.

Specifications Of High-Strength Shaft Forgings:

| Specifications | ASTM A182,ASTM A105,GB/T 12362,GB/T 1031 |

| Material | Alloy steel,Carbon steel,Carburizing steel,Quenched and tempered steel |

| Grade | Carbon Steel:4130,4140,4145,S355J2G3+N,S355NL+N,C20,C45,C35,etc. |

| Stainless Steel:17-4 PH,F22,304,321,316/316L,etc. | |

| Tool Steel:D2/1.2379,H13/1.2344,1.5919,etc. | |

| Surface Finish | Black, Bright, etc. |

| Heat treatment | Normalizing,Annealing,Quenching&Tempering, Surface Quenching,Case hardening |

| Machining | CNC Turning,CNC Milling,CNC Boring,CNC Grinding,CNC Drilling |

| Gear Machining | Gear Hobbing,Gear Milling,CNC Gear Milling,Gear Cutting,Spiral gear cutting,Gear Cutting |

| Mill Test Certificate | EN 10204 3.1 or EN 10204 3.2 |

Precision Bright Shaft Forgings Applications:

Forged Steel Shafts are versatile components widely used across numerous industries due to their exceptional strength, durability, and resistance to fatigue. Here are some of their key applications:

1. Automotive Industry:Crankshafts, camshafts, and axles in cars, trucks, and heavy vehicles.High-performance drivetrain components requiring superior mechanical properties.

2. Aerospace Industry:Precision-engineered shafts for jet engines and helicopter rotors.Structural components subjected to extreme temperatures and stress.

3. Power Generation:Turbine shafts in power plants (steam, gas, and hydroelectric turbines).Generator shafts and rotor shafts for renewable energy systems like wind turbines.

4. Industrial Machinery:Heavy-duty shafts for compressors, pumps, and gear systems.Rollers and spindles used in steel mills, paper mills, and manufacturing equipment.

5. Oil and Gas Industry:Drilling shafts and pump shafts used in oil exploration and extraction.Components for high-pressure, high-temperature environments.

6. Marine Industry:Propeller shafts and rudder stocks for ships and submarines.Corrosion-resistant forged steel shafts for offshore equipment.

7. Construction and Mining Equipment:Drive shafts and roller shafts in excavators, bulldozers, and mining equipment.Components that endure heavy loads and abrasive environments.

Features of Bright Shaft Forgings:

1.Strength and Durability:Forged shafts are renowned for their outstanding strength and long-lasting durability. The forging process enhances the alignment of the metal’s grain structure, which significantly improves its mechanical properties and resistance to fatigue.

2.Enhanced Metallurgical Properties:Through the forging process, the material undergoes significant refinement, resulting in superior metallurgical properties, including better grain flow. This leads to improved toughness and enhanced overall performance.

3.High Precision:Forging enables precise shaping of shafts, achieving tight dimensional tolerances and a superior surface finish, ensuring high-quality components for critical applications.

4.Tailored Customization:The forging process offers the flexibility to create shafts with specific shapes, sizes, and material properties, providing the ability to meet unique engineering requirements and custom specifications.

5.Reduced Material Waste:Compared to alternative manufacturing methods, forging is more efficient in terms of material usage, producing less waste. This makes it both a cost-effective and environmentally sustainable option.

Why Choose us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS ,TUV,BV 3.2 report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.

Forged Steel Shafts Packing:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,