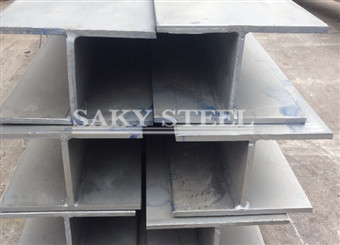

[Копиране] Неръждаема стомана IH Beam Bar

Кратко описание:

Спецификации на неръждаема стомана IH Beam bar:

Спецификации :DIN 1025 / EN 10034

степен:304, 304L, 316, 316L, 321

Дължина:6000, 6100 мм, 12000, 12100 мм и необходима дължина

технология:Горещо валцувани, заварени

Повърхностно покритие:Мариновано, ярко, полирано, грубо струговано, NO.4 покритие, матово покритие

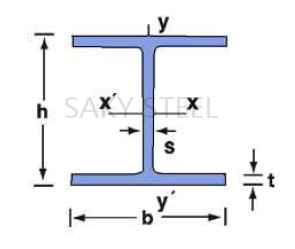

форма:HI греди

------- HEB (IPB) -------

СПОРЕД ПРОИЗВОДСТВОТО: DIN 1025 / EN 10034,

КАЧЕСТВО НА СТОМАНАТА: DIN 17100 / EN 10025

| ТЕГЛО | РАЗМЕРИ | ΔΙΑΤΟΜΗ | ΡΟΠΗ ΑΝΤΙΣΤΑΣΕΩΣ | |||||

| kg / m | mm | cm2 | cm3 | |||||

| h | b | s | t | F | Wx | Wy | ||

| 100 | 20 400 | 100 | 100 | 6,0 | 10,0 | 26,0 | 89,9 | 33,5 |

| 120 | 26 700 | 120 | 120 | 6,5 | 11,0 | 34,0 | 144,0 | 52,9 |

| 140 | 33 700 | 140 | 140 | 7,0 | 12,0 | 43,0 | 216,0 | 78,5 |

| 160 | 42 600 | 160 | 160 | 8,0 | 13,0 | 54,3 | 311,0 | 111,0 |

| 180 | 51 200 | 180 | 180 | 8,5 | 14,0 | 65,3 | 426,0 | 151,0 |

| 200 | 61 300 | 200 | 200 | 9,0 | 15,0 | 78,1 | 570,0 | 200,0 |

| 220 | 71 500 | 220 | 220 | 9,5 | 16,0 | 91,0 | 736,0 | 258,0 |

| 240 | 83 200 | 240 | 240 | 10,0 | 17,0 | 106,0 | 938,0 | 327,0 |

| 260 | 93 000 | 260 | 260 | 10,0 | 17,5 | 118,0 | 1150,0 | 395,0 |

| 280 | 103 000 | 280 | 280 | 10,5 | 18,0 | 131,0 | 1380,0 | 471,0 |

| 300 | 117 000 | 300 | 300 | 11,0 | 19,0 | 149,0 | 1680,0 | 571,0 |

| 320 | 127 000 | 320 | 300 | 11,5 | 20,5 | 161,0 | 1930,0 | 616,0 |

| 340 | 134 000 | 340 | 300 | 12,0 | 21,5 | 171,0 | 2160,0 | 646,0 |

| 360 | 142 000 | 360 | 300 | 12,5 | 22,5 | 181,0 | 2400,0 | 676,0 |

| 400 | 155 000 | 400 | 300 | 13,5 | 24,0 | 198,0 | 2880,0 | 721,0 |

| 450 | 171 000 | 450 | 300 | 14,0 | 26,0 | 218,0 | 3550,0 | 781,0 |

| 500 | 187 000 | 500 | 300 | 14,5 | 28,0 | 239,0 | 4290,0 | 842,0 |

| 550 | 199 000 | 550 | 300 | 15,0 | 29,0 | 254,0 | 4970,0 | 872,0 |

| 600 | 212 000 | 600 | 300 | 15,5 | 30,0 | 270,0 | 5700,0 | 902,0 |

| 650 | 225 000 | 650 | 300 | 16,0 | 31,0 | 286,0 | 6480,0 | 932,0 |

| 700 | 241 000 | 700 | 300 | 17,0 | 32,0 | 306,0 | 7340,0 | 963,0 |

| 800 | 262 000 | 800 | 300 | 17,5 | 33,0 | 334,0 | 8980,0 | 994,0 |

| 900 | 291 000 | 900 | 300 | 18,5 | 35,0 | 371,0 | 10980,0 | 1050,0 |

| 1000 | 314 000 | 1000 | 300 | 19,0 | 36,0 | 400,0 | 12890,0 | 1090,0 |

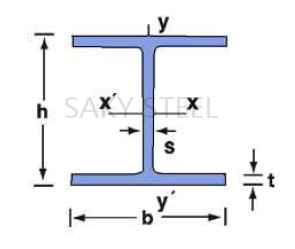

------- HEA-IPBL -------

СПОРЕД ПРОИЗВОДСТВОТО: DIN 1025 / EN 10034,

КАЧЕСТВО НА СТОМАНАТА: DIN 17100 / EN 10025

| ТЕГЛО | РАЗМЕРИ | ΔΙΑΤΟΜΗ | ΡΟΠΗ ΑΝΤΙΣΤΑΣΕΩΣ | |||||

| kg / m | mm | cm2 | cm3 | |||||

| h | b | s | t | F | Wx | Wy | ||

| 100 | 16 700 | 96 | 100 | 5,0 | 8,0 | 21,2 | 72,8 | 26,8 |

| 120 | 19 900 | 114 | 120 | 5,0 | 8,0 | 25,3 | 106,0 | 38,5 |

| 140 | 24 700 | 133 | 140 | 5,5 | 8,5 | 31,4 | 155,0 | 55,6 |

| 160 | 30 400 | 152 | 160 | 6,0 | 9,0 | 38,8 | 220,0 | 76,9 |

| 180 | 35 500 | 171 | 180 | 6,0 | 9,5 | 45,3 | 294,0 | 103,9 |

| 200 | 42 300 | 190 | 200 | 6,5 | 10,0 | 53,8 | 389,0 | 134,0 |

| 220 | 50 500 | 210 | 220 | 7,0 | 11,0 | 64,3 | 515,0 | 178,0 |

| 240 | 60 300 | 230 | 240 | 7,5 | 12,0 | 76,8 | 675,0 | 231,0 |

| 260 | 68 200 | 250 | 260 | 7,5 | 12,5 | 86,8 | 836,0 | 282,0 |

| 280 | 76 400 | 270 | 280 | 8,0 | 13,0 | 97,3 | 1010,0 | 340,0 |

| 300 | 88 300 | 290 | 300 | 8,5 | 14,0 | 112,0 | 1260,0 | 421,0 |

| 320 | 97 600 | 310 | 300 | 9,0 | 15,5 | 124,0 | 1480,0 | 466,0 |

| 340 | 105 000 | 330 | 300 | 9,5 | 16,5 | 133,0 | 1680,0 | 496,0 |

| 360 | 112 000 | 350 | 300 | 10,0 | 17,5 | 143,0 | 1890,0 | 526,0 |

| 400 | 125 000 | 390 | 300 | 11,0 | 19,0 | 159,0 | 2310,0 | 571,0 |

| 450 | 140 000 | 440 | 300 | 11,5 | 21,0 | 178,0 | 2900,0 | 631,0 |

| 500 | 155 000 | 490 | 300 | 12,0 | 23,0 | 198,0 | 3550,0 | 691,0 |

| 550 | 166 000 | 540 | 300 | 12,5 | 24,0 | 212,0 | 4150,0 | 721,0 |

| 600 | 178 000 | 590 | 300 | 13,0 | 25,0 | 226,0 | 4790,0 | 751,0 |

| 650 | 190 000 | 640 | 300 | 13,5 | 26,0 | 242,0 | 5470,0 | 782,0 |

| 700 | 204 000 | 690 | 300 | 14,5 | 27,0 | 260,0 | 6240,0 | 812,0 |

| 800 | 224 000 | 790 | 300 | 15,0 | 28,0 | 286,0 | 7680,0 | 843,0 |

| 900 | 252 000 | 890 | 300 | 16,0 | 30,0 | 320,0 | 9480,0 | 903,0 |

| 1000 | 272 000 | 990 | 300 | 16,5 | 31,0 | 347,0 | 11190,0 | 934,0 |

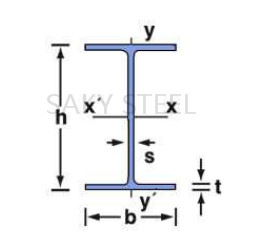

------- IPE ГРЕДИ -------

СПОРЕД ПРОИЗВОДСТВОТО: DIN 1025 / EN 10034

КАЧЕСТВО НА СТОМАНАТА: DIN 17100 / EN 10025

| ТЕГЛО | РАЗМЕРИ | ΔΙΑΤΟΜΗ | ΡΟΠΗ ΑΝΤΙΣΤΑΣΕΩΣ | |||||

| kg / m | mm | cm2 | cm3 | |||||

| h | b | s | t | F | Wx | Wy | ||

| 80 | 6000 | 80 | 46 | 3,8 | 5,2 | 7,64 | 20,0 | 3,69 |

| 100 | 8 100 | 100 | 55 | 4,1 | 5,7 | 10,30 | 34,2 | 5,79 |

| 120 | 10 400 | 120 | 64 | 4,4 | 6,3 | 13,20 | 53,0 | 8,65 |

| 140 | 12 900 | 140 | 73 | 4,7 | 6,9 | 16,40 | 77,3 | 12,30 |

| 160 | 15 800 | 160 | 82 | 5,0 | 7,4 | 20,10 | 109,0 | 16,70 |

| 180 | 18 800 | 180 | 91 | 5,3 | 8,0 | 23,90 | 146,0 | 22,20 |

| 200 | 22 400 | 200 | 100 | 5,6 | 8,5 | 28,50 | 194,0 | 28,50 |

| 220 | 26 200 | 220 | 110 | 5,9 | 9,2 | 33,40 | 252,0 | 37,30 |

| 240 | 30 700 | 240 | 120 | 6,2 | 9,8 | 39,10 | 324,0 | 47,30 |

| 270 | 36 100 | 270 | 135 | 6,6 | 10,2 | 45,90 | 429,0 | 62,20 |

| 300 | 42 200 | 300 | 150 | 7,1 | 10,7 | 53,80 | 557,0 | 80,50 |

| 330 | 49,100 | 330 | 160 | 7,5 | 11,5 | 62,60 | 713,0 | 98,50 |

| 360 | 57 100 | 360 | 170 | 8,0 | 12,7 | 72,70 | 904,0 | 123,00 |

| 400 | 66 300 | 400 | 180 | 8,6 | 13,5 | 84,50 | 1160,0 | 146,00 |

| 450 | 77 600 | 450 | 190 | 9,4 | 14,6 | 98,80 | 1500,0 | 176,00 |

| 500 | 90 700 | 500 | 200 | 10,2 | 16,0 | 116,00 | 1930,0 | 214,00 |

| 550 | 106 000 | 550 | 210 | 11,1 | 17,2 | 134,00 | 2440,0 | 254,00 |

| 600 | 122 000 | 600 | 220 | 12,0 | 19,0 | 156,00 | 3070,0 | 308,00 |

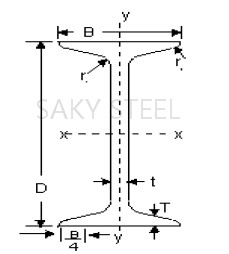

------- IPN -------

Наклон на фланеца на европейски стандартни греди IPN: 14%

| Сериен размер | Дълбочина X Ширина D X B | Единично тегло | Дебелина | Радиус | ||

| Web t | Фланец Т | Корен r1 | Пръст на крака r2 | |||

| mm | кг/м | mm | mm | mm | mm | |

| IPN 80 | 80 X 42 | 5,94 | 3.9 | 5.9 | 3.9 | 2.3 |

| IPN 100 | 100 х 50 | 8.34 | 4.5 | 6.8 | 4.5 | 2.7 |

| IPN 120 | 120 x 58 | 11.1 | 5.1 | 7.7 | 5.1 | 3.1 |

| IPN 140 | 140 x 66 | 14.3 | 5.7 | 8.6 | 5.7 | 3.4 |

| IPN 160 | 160 x 74 | 17.9 | 6.3 | 9.5 | 6.3 | 3.8 |

| IPN 180 | 180 x 82 | 21.9 | 6.9 | 10.4 | 6.9 | 4.1 |

| IPN 200 | 200 х 90 | 26.2 | 7.5 | 11.3 | 7.5 | 4.5 |

| IPN 220 | 220 x 98 | 31.1 | 8.1 | 12.2 | 8.1 | 4.9 |

| IPN 240 | 240 x 106 | 36.2 | 8.7 | 13.1 | 8.7 | 5.2 |

| IPN 260 | 260 x 113 | 41.9 | 9.4 | 14.1 | 9.4 | 5.6 |

| IPN 280 | 280 x 119 | 47.9 | 10.1 | 15.2 | 10.1 | 6.1 |

| IPN 300 | 300 x 125 | 54.2 | 10.8 | 16.2 | 10.8 | 6.5 |

| IPN 320 | 320 x 131 | 61,0 | 11.5 | 17.3 | 11.5 | 6.9 |

| IPN 340 | 340 x 137 | 68,0 | 12.2 | 18.3 | 12.2 | 7.3 |

| IPN 360 | 360 x 143 | 76.1 | 13 | 19.5 | 13 | 7.8 |

| IPN 380 | 380 x 149 | 84,0 | 13.7 | 20.5 | 13.7 | 8.2 |

| IPN 400 | 400 x 155 | 92.4 | 14.4 | 21.6 | 14.4 | 8.6 |

| IPN 450 | 450 x 170 | 115 | 16.2 | 24.3 | 16.2 | 9.7 |

| IPN 500 | 500 x 185 | 141 | 18 | 27 | 18 | 10.8 |

| IPN 550 | 550 x 200 | 166 | 19 | 30 | 19 | 11.9 |

Опаковка на SAKY STEEL:

1. Опаковането е много важно, особено в случай на международни пратки, при които пратката преминава през различни канали, за да достигне крайната дестинация, така че обръщаме специално внимание на опаковката.

2. Saky Steel опакова нашите стоки по много начини въз основа на продуктите.Ние опаковаме нашите продукти по много начини, като например,

Приложения:

IH греди от неръждаема стомана, произведени от sakysteel, могат да се използват в оборудване за обработка на храни, особено при варене на бира, преработка на мляко и производство на вино. Кухненски пейки, мивки, корита, оборудване и уреди. Архитектурни панели, парапети и облицовки. Топлообменници. Тъкани или заварени екрани за минно дело, кариери и филтриране на вода.Скрепителни елементи с резба.

![[Копиране] Представено изображение от неръждаема стомана IH Beam Bar](https://www.sakysteel.com/uploads/Stainless-Steel-H-Beam.jpg)

![[Копиране] Неръждаема стомана IH Beam Bar](https://www.sakysteel.com/uploads/Stainless-Steel-H-Beam-300x216.jpg)

![[Копиране] Неръждаема стомана IH Beam Bar](https://www.sakysteel.com/uploads/Stainless-Steel-I-Beam-300x216.jpg)

![[Копиране] Неръждаема стомана IH Beam Bar](https://www.sakysteel.com/uploads/Stainless-Steel-H-Beam-Bar-300x216.jpg)