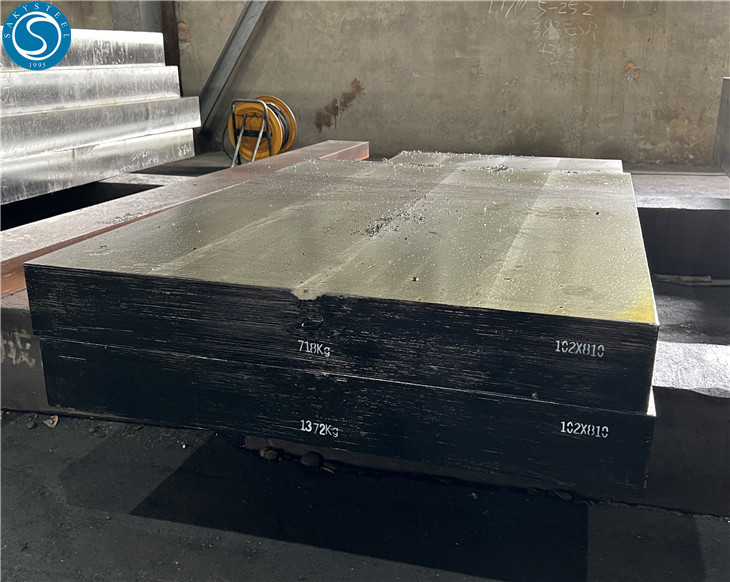

AISI D2 1.2379 Tool Steel Bar

Short Description:

D2 is a high-carbon, high-chromium tool steel known for its excellent wear resistance and good toughness. It’s often used in applications such as blanking dies, forming dies, and cutting tools.

1.2379 Tool Steel Bar:

D2 steel, available in round bar and plate forms, is ideal for manufacturing cold work molds with extensive cross-sections, intricate shapes, and demanding requirements for impact resistance and wear resistance. Also known as DIN 1.2379 and JIS SKD11 steel, it falls into the category of high-carbon, high-chromium cold work mold steels. This steel enjoys widespread use globally due to its exceptional hardenability and impressive resistance to high-temperature oxidation.Following quenching and polishing, D2 steel exhibits excellent anti-corrosion properties, and minimal deformation occurs during heat treatment processes.

Specifications Of D2 Steel Bar:

| Grade | D2,1.2379 |

| Standard | ASTM A681 |

| Surface | Black, Rough Machined, Turned |

| Length | 1 to 6 Meters |

| Processing | Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished |

| Raw Materail | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

D2 Steel Grade equivalent:

| Standard | ASTM A681-08 ALLOY TOOL STEEL | EN ISO 4957: 1999 TOOL STEEL | JIS | GOST |

| Grade | D2 | X153CrMoV12 | SKD11 | X153CrMoV12 |

D2 Steel Bar Chemical Composition:

| Stand | Grade | C | Mn | P | S | Si | Cr | V | Mo |

| ASTM A681-08 | D2 | 1.40-1.60 | 0.10-0.60 | ≤0.030 | ≤0.030 | 0.10-0.60 | 11.00-13.00 | 0.50-1.10 | 0.70-1.20 |

| JIS G4404: 2006 | SKD11 | 1.40-1.60 | ≤0.60 | ≤0.030 | ≤0.030 | 0.40 | 11.00-13.00 | 0.20-0.50 | - |

| EN ISO 4957:1999 | X153CrMoV12 | 1.45-1.60 | 0.20-0.60 | - | - | 0.10-0.60 | 11.00-13.00 | 0.70-1.00 | 0.70-1.00 |

| ISO 4957: 1999 | X153CrMoV12 | 1.45-1.60 | 0.20-0.60 | - | - | 0.10-0.60 | 11.00-13.00 | 0.70-1.00 | 0.70-1.00 |

1.2379 Steel Bar Physical Properties:

| PROPERTIES | METRIC | IMPERIAL |

| DENSITY | 7.7 * 1000kg/m³ | 0.278 lb/in³ |

| MELTING POINT | 1421℃ | 2590°F |

Why Choose us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS TUV report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.

Packing:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,