About Saky Steel Co.,Ltd

Brief Introduction

Saky Steel Co.,Ltd is located in Jiangsu Province. The company was founded in 1995. Now the company covers totally 220,000 square meters . The company has a total employee of 150 out of whom 120 are professionals .The company has been continually expanding itself ever since it’s founded . Now the company is a ISO9001:2000 certified company and has been continually awarded by the local government .

The company through investment steel smelting and forging factory resume stability, a wide range of available resources.Main produce and process stainless steel bar/rod/shaft/profile,stainless steel pipe/tube, stainless steel coil/sheet/plate/strip, stainless steel wire/wire rod/wire rope. Our company supply products from SAKY,TISCO, LISCO, BAOSTEEL, JISCO and so on.We can customize non-standard special stainless steel products with high quality with short time. Our products used to chemical treatment equipments, chemicals tanks, petrochemical equipment and press plates. It is also used in railway coaches, roof drainage products, storm door frames, food machinery and tableware.

Our company developed international markets more than 20 years, and established long partnership with Germany, South American ,Australia, Saudi Arabia ,Southeast Asia. etc . We will be on the basic of advanced management and service concept to provide high quality products and perfect service for all over the manufacturing enterprise. We welcome customers from all over the world to cooperate with us.

Pipe Annealing

Stainless Plate UT Testing

Stainless bar UT Inspecting

Factory Supply

We specialize in the production of stainless steel bar such as 304, 316, 321, and more. Our stainless steel rod production process is carefully refined to ensure that every product meets the required standards. First, we select high-quality stainless steel raw materials, which undergo smelting and refining to remove impurities and ensure the purity of the metal. Next, the raw materials enter the continuous casting process to form initial billets. The billets are then heated to the appropriate temperature in a furnace and undergo extrusion or forging processes, being gradually pressed and shaped through multiple stages to achieve the desired diameter and length. During the cooling and straightening stages, we employ precise control to ensure the rods' surfaces are smooth and flat, preventing any deformation. Finally, through cutting, polishing, and inspection, we ensure that each stainless steel rod meets strict quality standards, delivering perfection to our customers.

Why Choose Us

● Supplying stainless steel sheets, pipes, bars, wires, and profiles in various specifications.

● Material options: 304, 316, 316L, 310S, 321, 430, and more.

● Customized sizes and surface finishes (e.g., brushed, mirror, sandblasted).

● Cutting Services: Precision cutting with laser, plasma, or water jet based on client designs.

● Welding and Assembly: Professional welding services, including TIG welding and laser welding, to produce finished products like stainless steel containers and frames

● Bending, rolling, and stretching stainless steel materials into desired shapes.

● Offering diverse surface treatments: brushing, mirror polishing, sandblasting, and passivation to meet decorative or corrosion-resistant requirements.

● Special surface finishes (e.g., PVD coating) to enhance durability and aesthetics.

● Recommending appropriate stainless steel grades for specific environments (e.g., marine, chemical, or high-temperature applications).

● Providing custom solutions for oxidation and acid/alkali resistance.

● Expert engineering support to help customers choose the right stainless steel grades and processing techniques.

● Offering tailored material selection advice for projects to ensure performance requirements are met.

● Supporting new product development based on specific customer needs and participating in the creation of innovative stainless steel solutions.

● Providing sample fabrication and small-batch trial production to ensure compliance with standards.

Project Applications

Fergana Refinery Revamp Project

Compression Project to Process

Water Pipeline Project

BR Project

Tank

Prisxsta Yasany

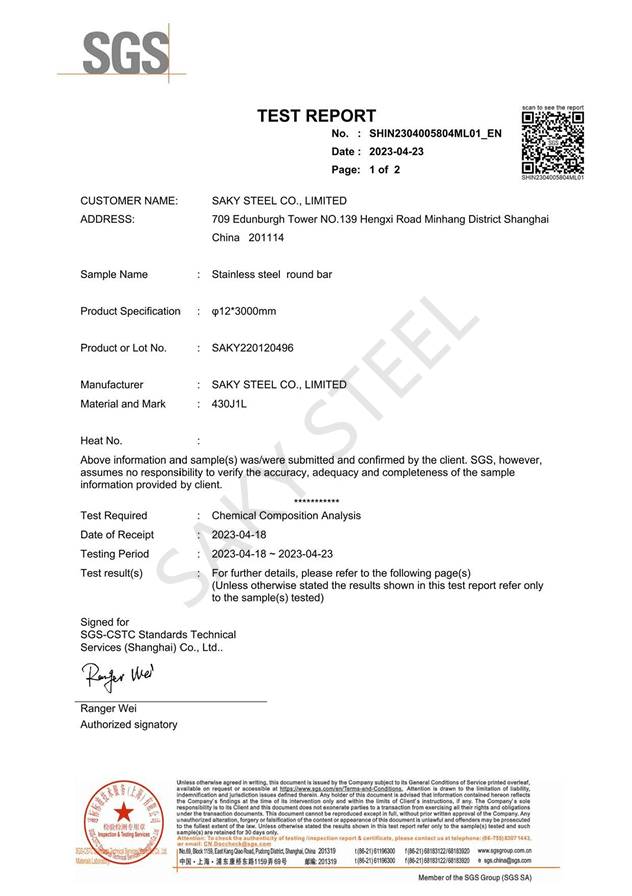

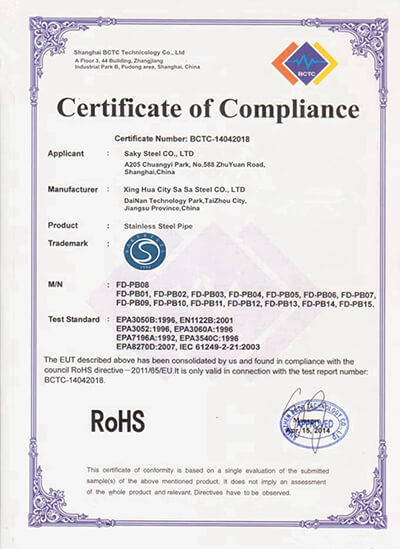

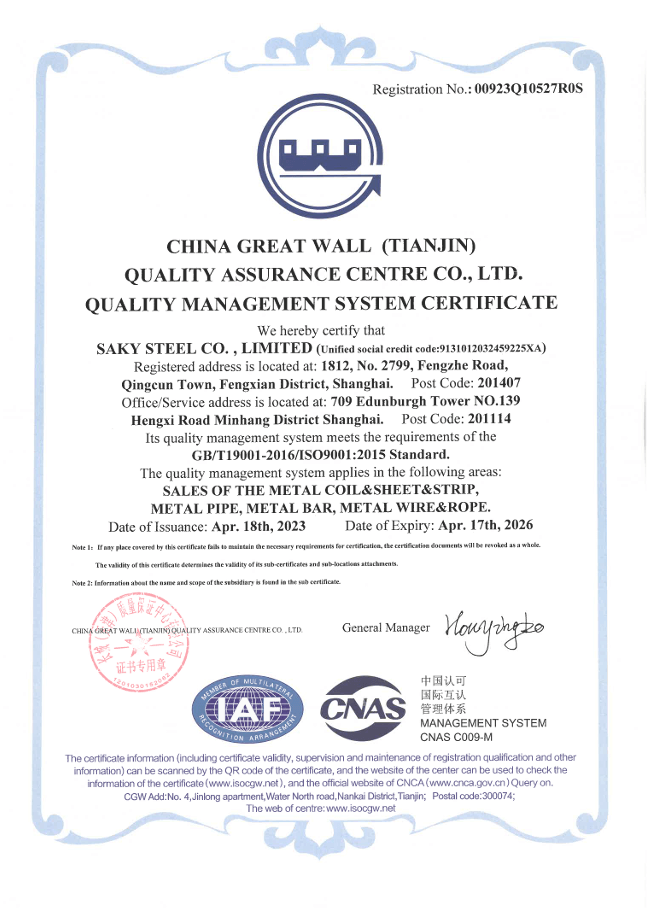

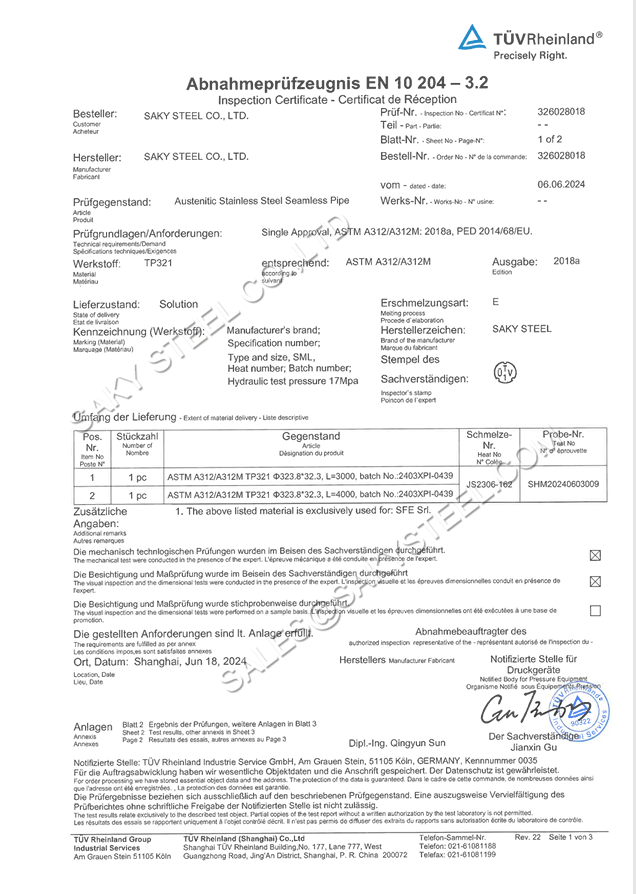

Certificates

ISO

SGS

TUV

RoHS

ISO2

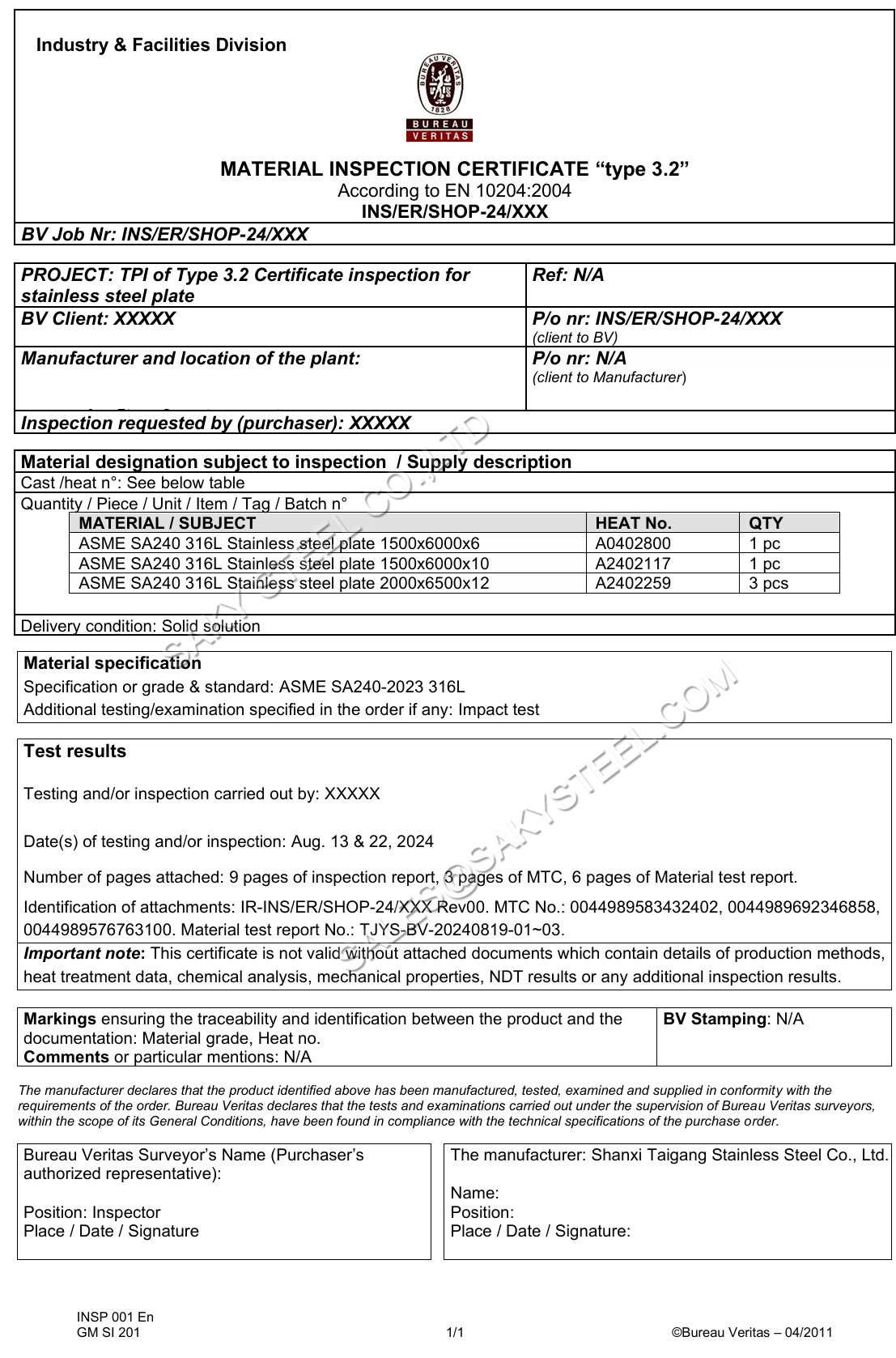

3.21 Certificate

BV 3.2 Cetificate

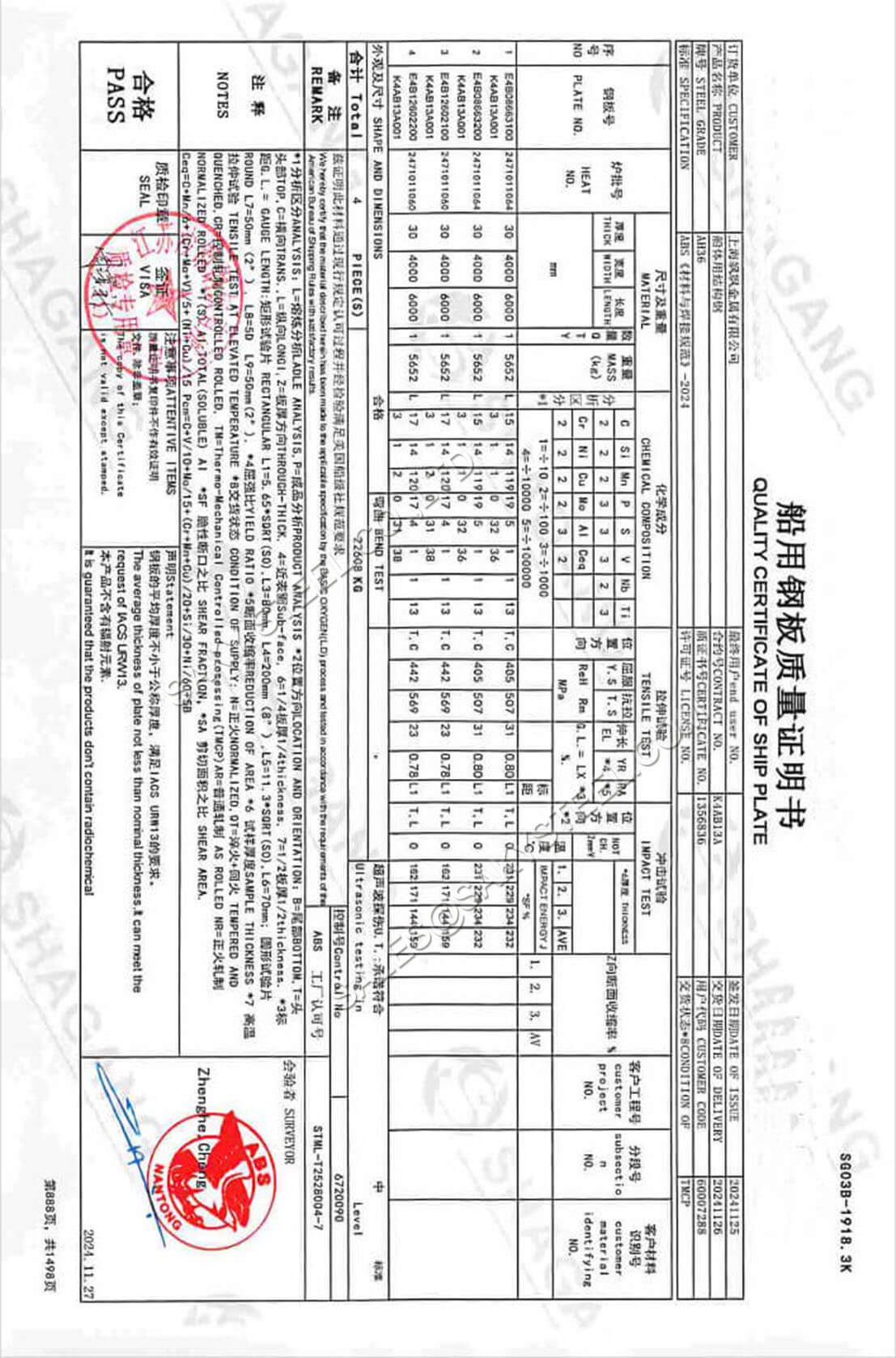

ABS 3.2 Cetificate

Feel Free To Ask Us Anything, We Are Here 24 hours Online For You.

What Our Valuable Partners Say About Us

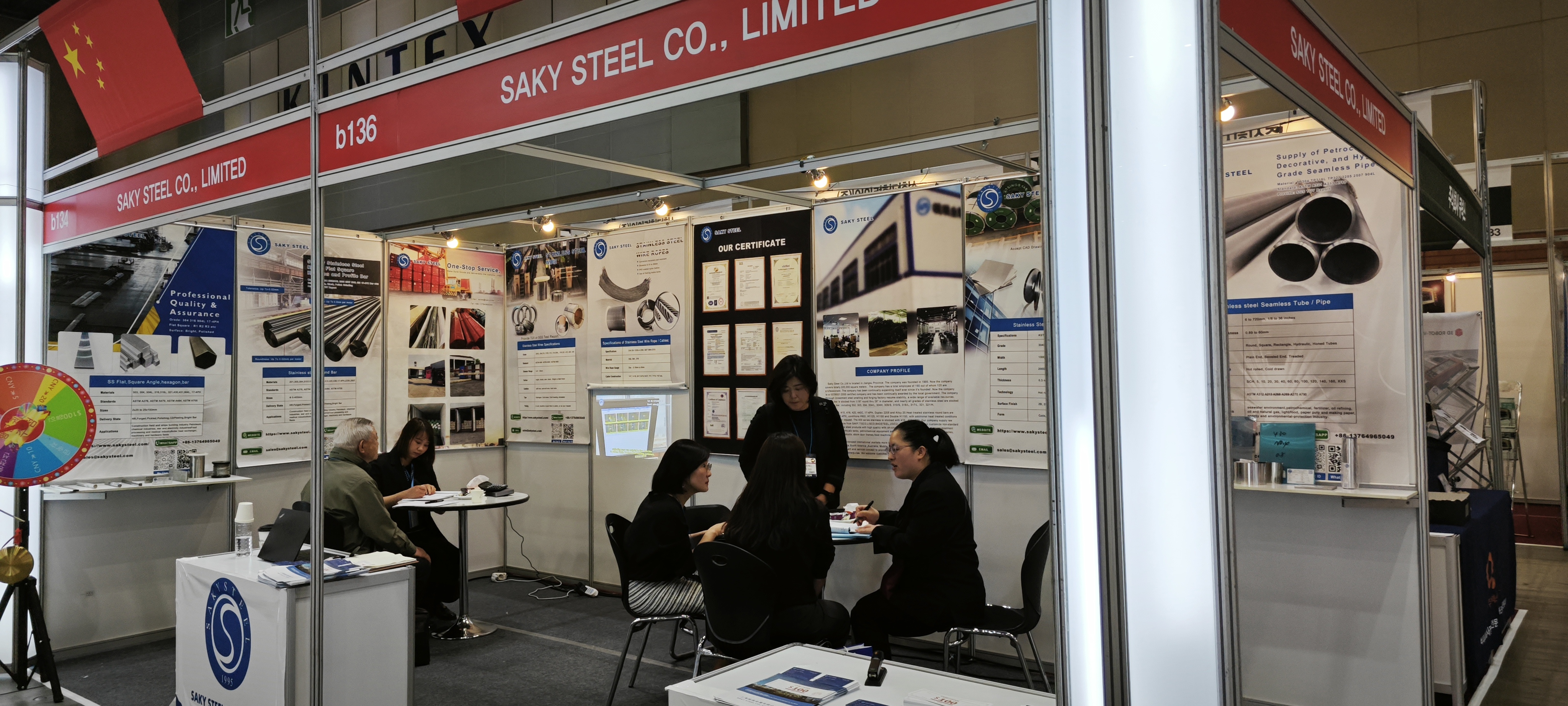

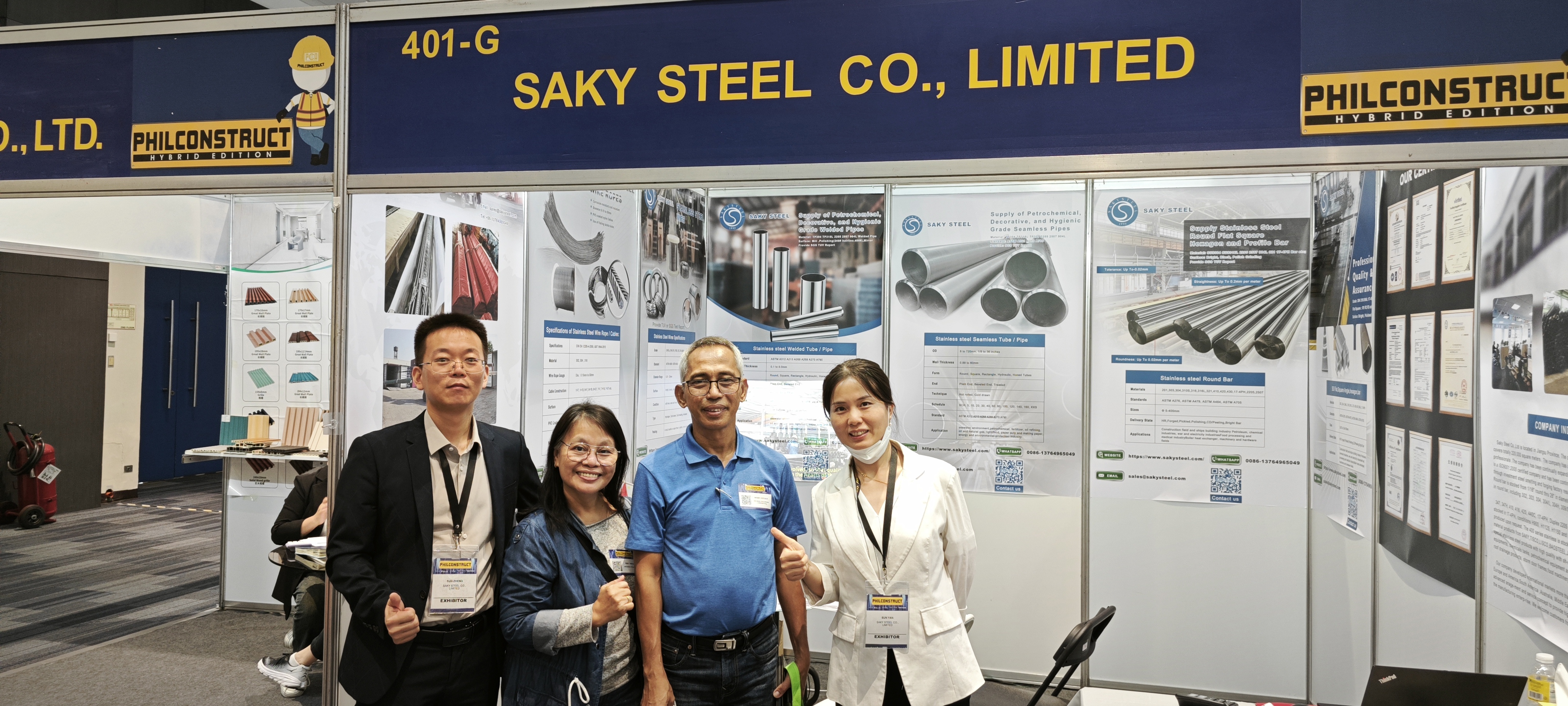

Meet Us in Exhibitions