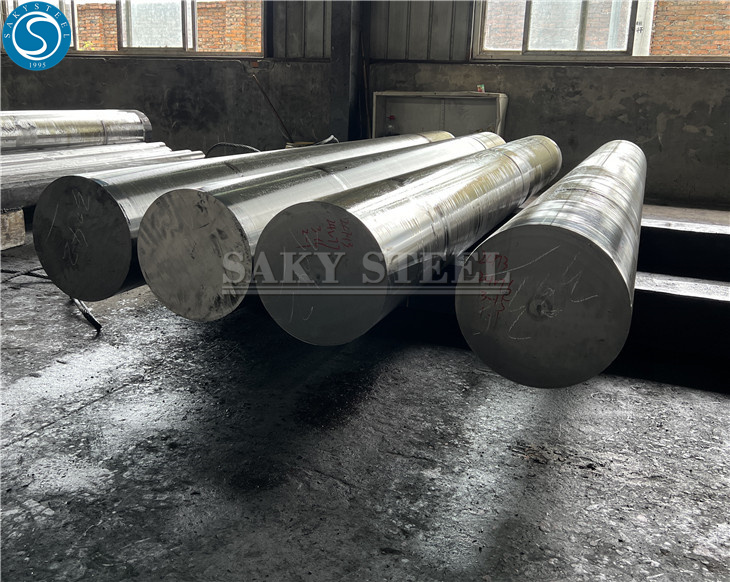

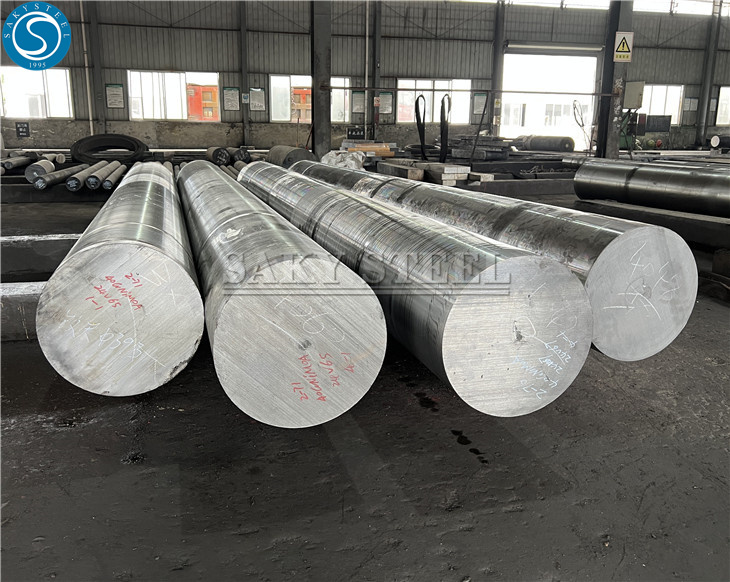

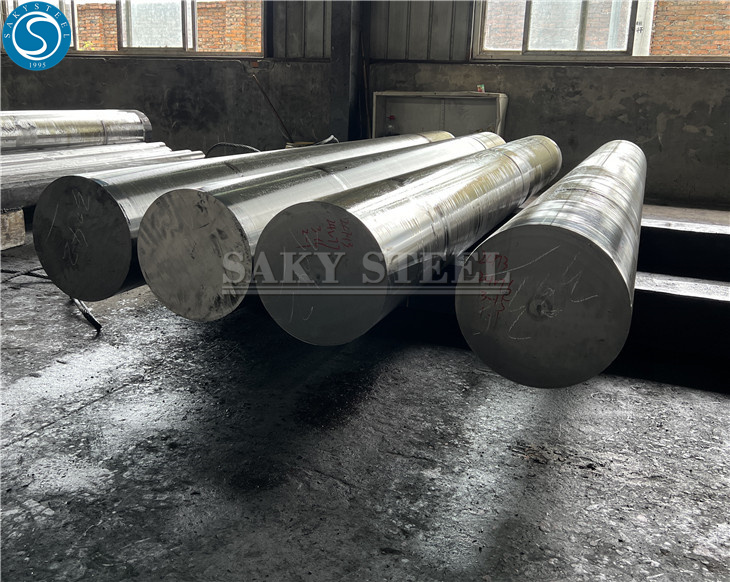

86CRMOV7 1.2327 Tool Steel

Short Description:

86CRMOV7 (1.2327) tool steel offers excellent wear resistance, high toughness, and thermal stability. Ideal for mold making, automotive, and aerospace industries.

86CRMOV7 1.2327 Tool Steel:

86CRMOV7 (1.2327) Tool Steel is a high-performance alloy steel known for its excellent wear resistance, high toughness, and thermal stability. With a carefully balanced chemical composition, it offers superior hardenability and strength, making it ideal for demanding applications such as mold making, cutting tools, and industrial machinery. This tool steel is widely used in the automotive, aerospace, and defense industries, where durability and precision are critical. Its consistent performance under extreme conditions ensures reliability and longevity, making it a preferred choice for high-quality tooling solutions.

Specifications Of H11 1.2378 TOOL STEELS:

| Grade | 86CRMOV7, 1.2327 |

| Surface | Black; Peeled; Polished; Machined; Grinded; Turned; Milled |

| Processing | Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished |

| Mill Test Certificate | En 10204 3.1 or En 10204 3.2 |

1.2327 TOOL STEELS equivalent:

| DIN | AISI | JIS | ISO |

| 1.2327 | 86CrMoV7 | SKD7 | X86CrMoV7 |

1.2327 TOOL STEELS Chemical Composition:

| C | Si | Mn | S | Cr | Mo | V | P |

| 0.83-0.90 | 0.15-0.35 | 0.30-0.45 | 0.030 | 1.6-1.9 | 0.2-0.35 | 0.05-0.15 | 0.03 |

86CRMOV7 TOOL STEELS Mechanical Properties:

| Tensile strength (MPa) | Elongation (%) | Yield Strength(MPa) | Hardness (HRC) |

| 2000 | 10 | 1500 | 58-62 |

Features of 1.2327 Tool Steel:

• High Hardness and Wear Resistance: After quenching, the hardness can reach above 60HRC, making it suitable for high-strength and wear-resistant working conditions.

• Excellent Toughness: Maintains good impact resistance even under high-strength conditions.

• Strong Thermal Stability: Suitable for high-temperature operations with excellent dimensional stability.

• Market Demand: Due to its outstanding performance, 86CRMOV7 1.2327 is highly popular in the global tool steel market, especially in the precision manufacturing and high-wear mold industries.

Applications of 1.2327 Tool Steel:

1.Automotive Manufacturing: Used for high-strength stamping dies and engine components.

2.Aerospace: Produces high-temperature, high-strength structural components.

3.Military Manufacturing: Applied in precision weapon parts and military-grade molds.

4.Plastic Molds: Suitable for high-wear plastic molding dies, extending service life.

Why Choose us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS TUV report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.

Our Services

1.Quenching and tempering

2.Vacuum heat treating

3.Mirror-polished surface

4.Precision-milled finish

4.CNC machining

5.Precision drilling

6.Cut into smaller sections

7.Achieve mold-like precision

Packing:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,