446 Stainless steel pipe

Short Description:

Discover 446 stainless steel pipes with superior high-temperature and corrosion resistance. Ideal for industrial applications.

Stainless Steel Pipe Hydrostatic Testing:

446 stainless steel pipe is a ferritic stainless steel characterized by its high chromium content, offering excellent high-temperature oxidation resistance and corrosion resistance. Due to its unique alloy composition, 446 stainless steel pipe performs exceptionally well under extreme temperature conditions, making it widely used in high-temperature industrial equipment, boilers, heat exchangers, and combustion chambers. Additionally, because of its superior corrosion resistance, 446 stainless steel pipe is commonly used in chemical, petroleum, and marine engineering applications. By choosing 446 stainless steel pipe, you will obtain outstanding product quality and reliable performance to meet the demands of various rigorous applications.

Specifications of 446 Stainless Steel Seamless Tube:

| Specifications | ASTM A 268 |

| Dimensions | ASTM, ASME and API |

| SS 446 | 1/2″ NB – 16″ NB |

| Size | 1/8″NB TO 30″NB IN |

| Specialized in | Large Diameter Size |

| Schedule | SCH20, SCH30, SCH40, XS, STD, SCH80, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Type | Seamless |

| Form | Rectangular, Round, Square, Hydraulic Etc |

| Length | Double Random, Single Random & Cut Length. |

| End | Beveled End, Plain End, Treaded |

446 SS Pipe Chemical Composition:

| Grade | C | Si | Mn | S | P | Cr | Ni | N |

| 446 | 0.20 | 1.0 | 1.0 | 0.030 | 0.040 | 23.0-27.0 | 0.75 | 0.25 |

Mechanical Properties of 446 Stainless Steel Pipe:

| Grade | Tensile Strength (MPa) min | Elongation (% in 50mm) min | Yield Strength 0.2% Proof (MPa) min | Density | Melting Point |

| 446 | Psi – 75,000 , MPa – 485 | 20 | Psi – 40,000 , MPa – 275 | 7.5 g/cm3 | 1510 °C (2750 °F) |

Applications of 446 Stainless Steel Pipes:

446 stainless steel pipes are widely used in various demanding environments due to their excellent high-temperature and corrosion resistance. In industrial equipment, they are commonly used in furnaces, heat exchangers, and boilers. In the chemical and petrochemical industries, they are suitable for transporting high-temperature corrosive fluids. The energy sector uses them in power plants and the nuclear industry. In marine engineering, 446 stainless steel pipes are used in seawater systems and offshore platforms. Additionally, they play a significant role in construction, automotive, aerospace, and food and beverage industries, being ideal for high-temperature sterilization and hot liquid transportation. These characteristics make them a reliable choice for various high-demand applications.

Benefits of 446 Stainless Steel Pipes:

1.Thermal Stability: 446 stainless steel pipes maintain their strength and structural integrity at high temperatures, making them ideal for high-temperature industrial applications.

2.Chemical Resistance: 446 stainless steel is highly resistant to a wide range of corrosive environments, including acidic and alkaline conditions, making it suitable for chemical processing applications.

3.Wear and Tear: The robust nature of 446 stainless steel pipes ensures they can withstand mechanical wear and tear, reducing the need for frequent replacements and maintenance.

4.Long Service Life: Due to their high resistance to corrosion and thermal stress, these pipes offer a longer service life compared to other materials.

5.Strength: 446 stainless steel pipes have excellent mechanical properties, providing the necessary strength for high-stress applications.

6.Integrity Maintenance: They maintain their structural integrity under high loads and in harsh environments, ensuring reliability and safety.

Why Choose Us?

1.With over 20 years of experience, our team of experts ensures top-notch quality in every project.

2.We adhere to stringent quality control processes to ensure every product meets the standards.

3.We leverage the latest technology and innovative solutions to deliver superior products.

4.We offer competitive pricing without compromising on quality, ensuring you get the best value for your investment.

5.We offer a comprehensive range of services to meet all your needs, from initial consultation to final delivery.

6.Our commitment to sustainability and ethical practices ensures that our processes are environmentally friendly.

Our Service:

1.Quenching and tempering

2.Vacuum heat treating

3.Mirror-polished surface

4.Precision-milled finish

4.CNC machining

5.Precision drilling

6.Cut into smaller sections

7.Achieve mold-like precision

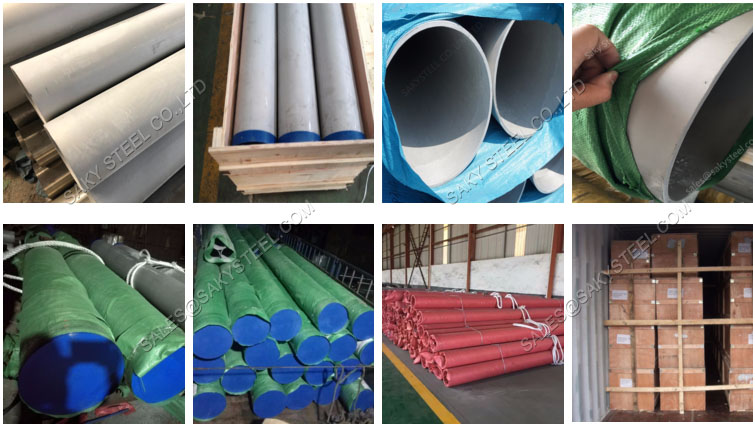

Corrosion-resistant Steel Pipe Packaging:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,