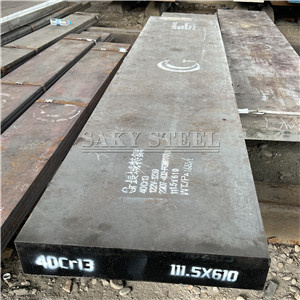

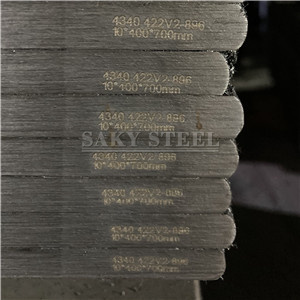

4340 Steel Plate

Short Description:

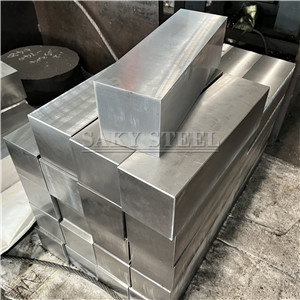

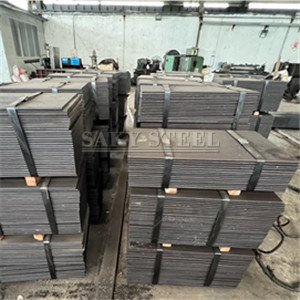

4340 steel plates are typically produced through hot rolling or cold rolling processes and are available in various thicknesses and dimensions. The plates are often supplied in a normalized or tempered condition to enhance their strength and toughness.

4340 steel plates are widely used in industries that require high-strength and durable materials. They find applications in aerospace, automotive, oil and gas, machinery, and other engineering sectors. Some common uses of 4340 steel plates include manufacturing of gears, shafts, crankshafts, connecting rods, tooling components, and structural parts subjected to high stress and impact loads.

| Specifications Of 4340 Steel Plate |

| Specification | SAE J404, ASTM A829 / ASTM A6, AMS 2252/ 6359/ 2301 |

| Grade | AISI 4340/ EN24 |

| Value Added Services |

|

| Thickness chart of 4340 Plate |

| Dimension thickness is in inches | ||

| 0.025″ | 4″ | 0.75″ |

| 0.032″ | 3.5″ | 0.875″ |

| 0.036″ | 0.109″ | 1″ |

| 0.04″ | 0.125″ | 1.125″ |

| 0.05″ | 0.16″ | 1.25″ |

| 0.063″ | 0.19″ | 1.5″ |

| 0.071″ | 0.25″ | 1.75″ |

| 0.08″ | 0.3125″ | 2″ |

| 0.09″ | 0.375″ | 2.5″ |

| 0.095″ | 0.5″ | 3″ |

| 0.1″ | 0.625″ | |

| Commonly Used Types Of 4340 Steel Plates |

AMS 6359 Plate |

4340 Steel Plate |

EN24 Aq Steel Plate |

4340 Steel Sheet |

36CrNiMo4 Plate |

DIN 1.6511 Plate

|

| Chemical Composition of 4340 Steel Sheet |

| Grade | Si | Cu | Mo | C | Mn | P | S | Ni | Cr |

4340 |

0.15/0.35 | 0.70/0.90 | 0.20/0.30 | 0.38/0.43 | 0.65/0.85 | 0.025 max. | 0.025 max. | 1.65/2.00 | 0.35 max. |

| EQUIVALENT GRADES OF 4340 Steel Sheet |

| AISI | Werkstoff | BS 970 1991 | BS 970 1955 EN |

| 4340 | 1.6565 | 817M40 | EN24 |

| 4340 Material Tolerance |

| Thick, inch | Tolerance Range, Inch. | |

| 4340 Annealed | Up – 0.5, excl. | +0.03 Inch, -0.01 Inch |

| 4340 Annealed | 0.5 – 0.625, excl. | +0.03 Inch, -0.01 Inch |

| 4340 Annealed | 0.625 – 0.75, excl. | +0.03 Inch, -0.01 Inch |

| 4340 Annealed | 0.75 – 1, excl. | +0.03 Inch, -0.01 Inch |

| 4340 Annealed | 1 – 2, excl. | +0.06 Inch, -0.01 Inch |

| 4340 Annealed | 2 – 3, excl. | +0.09 Inch, -0.01 Inch |

| 4340 Annealed | 3 – 4, excl. | +0.11 Inch, -0.01 Inch |

| 4340 Annealed | 4 – 6, excl. | +0.15 Inch, -0.01 Inch |

| 4340 Annealed | 6 – 10, excl. | +0.24 Inch, -0.01 Inch |

| Why Choose Us |

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. e guarantee to give a response within 24hours(usually in the same hour)

5. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.