416 Stainless Steel Flat Bar

Short Description:

UNS S41600 Flat Bars, SS 416 Flat Bars, AISI SS 416 Stainless Steel 416 Flat Bars Supplier, Manufacturer and Exporter in China.

416 Stainless Steel. 416 Stainless Steel Flat bar is a martensitic free machining grade of stainless that can be hardened by heat treatment to achieve elevated strength and hardness. Due to its low cost and ready machinability, 416 stainless steel is readily used in its highly tempered state. It exhibits better machining characteristics than austenitic grades, however, sacrifices corrosion resistance. High sulfur, free-machining grades like Alloy 416 are unsuitable for marine or any chloride exposure situations.

| 416 Stainless Steel Flat Bar Spections: |

| Specification: | ASTM A582/A 582M-05 ASTM A484 |

| Material: | 303 304 316 321 416 420 |

| Stainless Steel Round Bars: | Outside Diameter in the range of 4mm to 500mm |

| Width: | 1mm to 500mm |

| Thickness: | 1mm to 500mm |

| Technique: | Hot Rolled Annealed & Pickled (HRAP) & Cold drawn & Forged & Cut Sheet and Coil |

| Length: | 3 to 6 Meters / 12 to 20 feet |

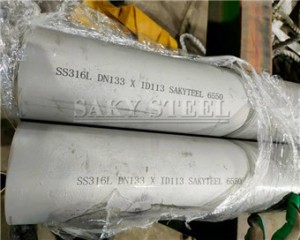

| Marking: | Size, Grade, Manufacture name on Each Bars/Pieces |

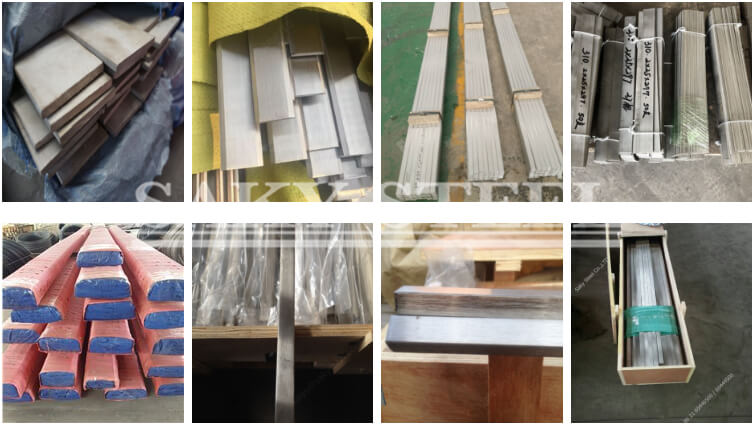

| Packing: | Each steel bar has the singal, and several will be bundled by weaving bag or as per requirement. |

| Stainless Steel 416 Flat Bars Equivalent Grades: |

| STANDARD | JIS | WERKSTOFF NR. | AFNOR | BS | GOST | UNS |

| SS 416 |

SUS 416 | 1.4005 | - | - | - | S41600 |

| 416 Free-Machining SS Flat Bars Chemical Composition and Mechanical properties(saky steel): |

| Grade | C | Mn | Si | P | S | Cr | Ni |

| SS 416 |

0.15 max | 1.25 max | 1.0 max | 0.060 max | 0.15 min | 12.0 – 14.0 | - |

| Types | Condition | Hardness (HB) |

| All (except 440F, 440FSe and S18235) |

A | 262 max |

| 416, 416Se, 420FSe, and XM-6 | T | 248 to 302 |

| 416, 416Se, and XM-6 | H | 293 to 352 |

| 440 F and 440FSe | A | 285 max |

| S18235 | A | 207 max |

A Sizes below approximately 1 in. [25 mm] cross section may be tensile tested and converted to hardness in accordance with Test Methods and Definitions A 370.

| SAKY STEEL’S Quality Assurance (including both Destructive and Non-Destructive) : |

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Ultrasonic test

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Impact analysis

10. Metallography Experimental Test

| Packaging: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,

Applications:

Applications requiring moderate corrosion resistance and high mechanical properties are ideal for Alloy 416. Examples of applications that frequently used Alloy 416 include:

Cutlery

Steam and gas turbine blades

Kitchen utensils

Bolts, nuts, screws

Pump and valve parts and shafts

Mine ladder rugs

Dental and surgical instruments

Nozzles

Hardened steel balls and seats for oil well pumps