4130 Alloy Steel Seamless Pipe

Short Description:

4130 Alloy Steel Pipe:

4130 alloy steel pipe is a low-alloy steel containing chromium and molybdenum as strengthening agents. It offers a good balance of strength, toughness, and weldability, making it ideal for applications that require high strength and durability, such as in aerospace, automotive, and oil and gas industries. The alloy is also known for its excellent fatigue resistance and is commonly used in structural components like frames, shafts, and pipelines. Additionally, 4130 steel can be heat-treated to enhance its mechanical properties, further improving its performance in demanding environments.

Specifications of 4130 Steel Seamless Tube:

| Specifications | ASTM A 519 |

| Grade | 4130 |

| Schedule | SCH20, SCH30, SCH40, XS, STD, SCH80, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Type | Seamless |

| Form | Rectangular, Round, Square, Hydraulic Etc |

| Length | 5.8M,6M & Required Length |

| End | Beveled End, Plain End, Treaded |

| Mill Test Certificate | EN 10204 3.1 or EN 10204 3.2 |

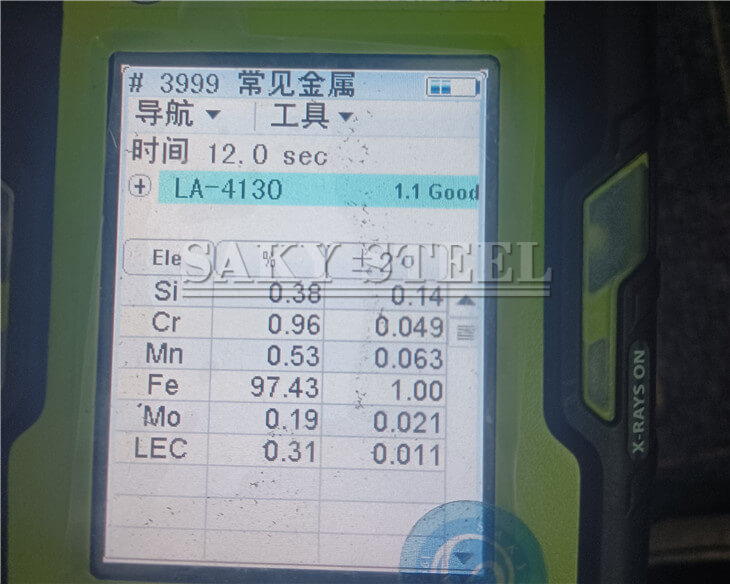

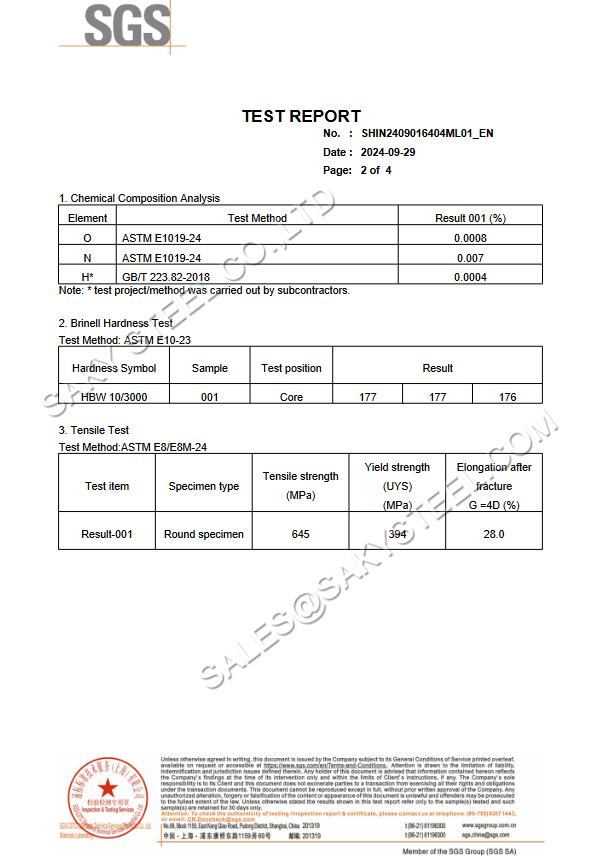

AISI 4130 Pipes Chemical Composition:

| Grade | C | Si | Mn | S | P | Cr | Ni | Mo |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.4-0.6 | 0.025 | 0.035 | 0.08-1.10 | 0.50 | 0.15-0.25 |

Mechanical Properties of 4130 Round Pipes:

| Grade | Tensile Strength (MPa) min | Elongation (% in 50mm) min | Yield Strength 0.2% Proof (MPa) min |

| 4130 | MPa – 560 | 20 | MPa – 460 |

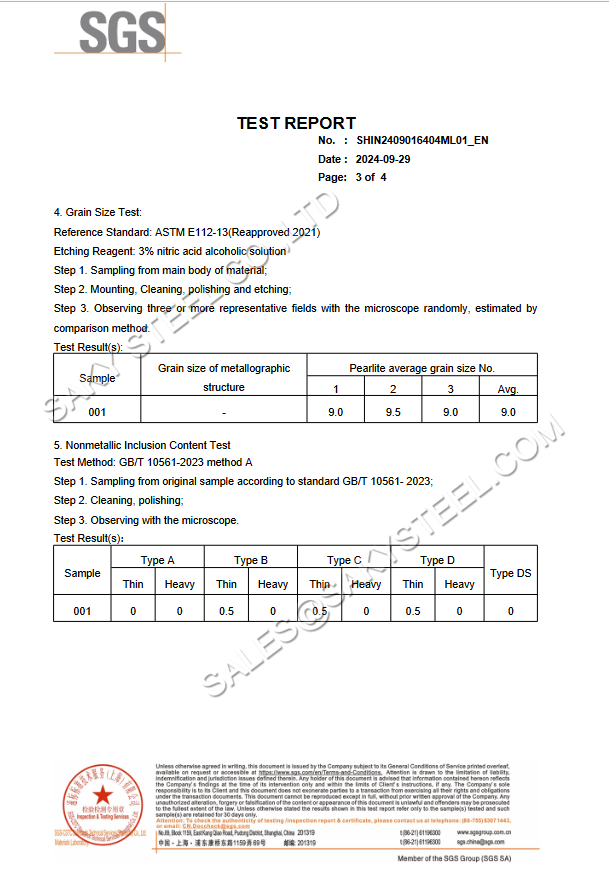

UNS G41300 Steel Round Tube Test:

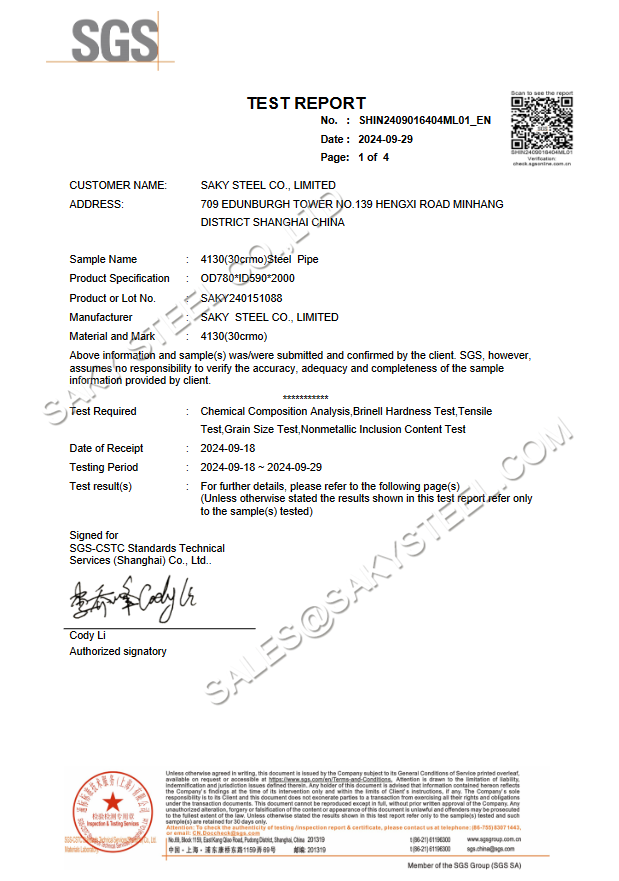

4130 Alloy Steel Round Tube Certificate:

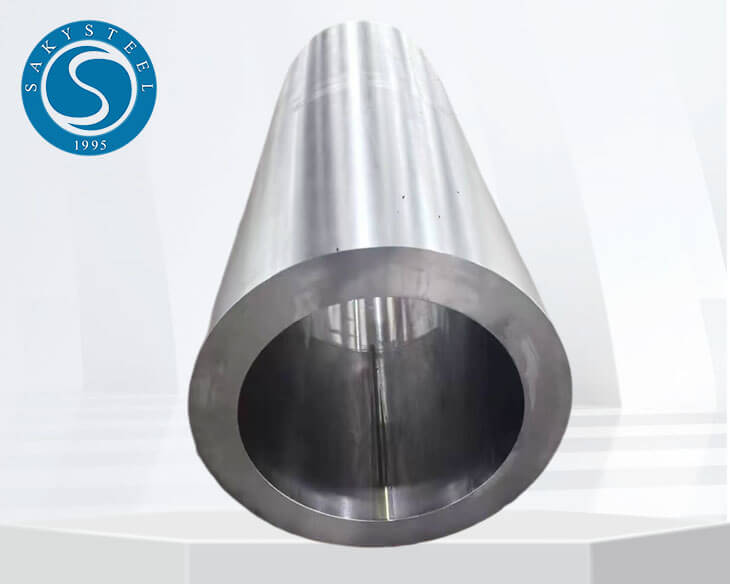

UNS G41300 Steel Round Tube Rough Turning:

Rough turning is the initial machining process used to remove large amounts of material from a 4130 alloy steel seamless pipe. This process is crucial in shaping the workpiece to a near-final form before finishing operations. 4130 alloy steel, known for its strength, toughness, and good machinability, responds well to this process, allowing for efficient material removal. During rough turning, a lathe or CNC machine is used to quickly cut down the diameter of the pipe, preparing it for precision turning or other secondary operations. Proper tool selection and cooling are essential to manage heat and ensure optimal surface quality and tool life.

Benefits of 4130 Alloy Steel Seamless Pipe:

1.High Strength-to-Weight Ratio: 4130 alloy steel offers excellent strength while maintaining a relatively low weight, making it ideal for applications requiring both durability and reduced material weight, such as in the aerospace and automotive industries.

2.Good Weldability: Despite its high strength, 4130 alloy steel is known for its weldability. It can be welded using various methods (TIG, MIG) without the need for extensive preheating, making it versatile for structural fabrication.

3.Toughness and Fatigue Resistance: The alloy provides superior toughness and high fatigue resistance, making it suitable for demanding applications like high-pressure tubing and mechanical components subject to stress.

4.Corrosion Resistance: Though not as corrosion-resistant as stainless steel, 4130 alloy steel performs well in mild environments when properly coated or treated, extending its lifespan in challenging conditions.

5.Good Machinability: 4130 alloy steel is relatively easy to machine compared to other high-strength steels, making it cost-effective in manufacturing processes, including turning, milling, and drilling.

6.Versatile Applications: The seamless construction and high strength make 4130 alloy steel pipe ideal for critical applications such as hydraulic tubing, oil and gas drilling, structural frameworks, and aerospace components.

Why Choose Us?

1.With over 20 years of experience, our team of experts ensures top-notch quality in every project.

2.We adhere to stringent quality control processes to ensure every product meets the standards.

3.We leverage the latest technology and innovative solutions to deliver superior products.

4.We offer competitive pricing without compromising on quality, ensuring you get the best value for your investment.

5.We offer a comprehensive range of services to meet all your needs, from initial consultation to final delivery.

6.Our commitment to sustainability and ethical practices ensures that our processes are environmentally friendly.

Our Service:

1.Quenching and tempering

2.Vacuum heat treating

3.Mirror-polished surface

4.Precision-milled finish

4.CNC machining

5.Precision drilling

6.Cut into smaller sections

7.Achieve mold-like precision

High Strength Alloy Pipe Packaging:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,