347 Stainless Steel Seamless Pipe

Short Description:

347 Stainless Steel Seamless Pipe: High-Temperature Resistance & Corrosion Protection.

Stainless Steel Pipe Roughness Testing:

347 Stainless Steel Seamless Pipes are made from a stabilized grade of stainless steel, designed to offer excellent resistance to intergranular corrosion, particularly in high-temperature environments. These pipes are ideal for applications requiring superior creep strength and oxidation resistance, such as in chemical processing, power generation, and high-heat exhaust systems. With added niobium, 347 stainless steel provides enhanced stability, preventing carbide precipitation and maintaining its strength in temperatures up to 1500°F (816°C). This makes 347 stainless steel seamless pipes perfect for demanding environments requiring durability and long-term reliability.

Specifications of Stainless Steel 347 Seamless Pipe:

| Specifications | ASTM A/ASME SA213, A249, A269, A312, A358, A790 |

| Grade | 304, 316, 321, 321Ti, 347, 347H, 904L, 2205, 2507 |

| Techniques | Hot-rolled, cold-drawn |

| Size | 1 / 8" NB - 12" NB |

| Thickness | 0.6 mm to 12.7 mm |

| Schedule | SCH20, SCH30, SCH40, XS, STD, SCH80, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Type | Seamless |

| Form | Rectangular, Round, Square, Hydraulic Etc |

| Length | 5.8M,6M & Required Length |

| End | Beveled End, Plain End, Treaded |

| Mill Test Certificate | EN 10204 3.1 or EN 10204 3.2 |

Stainless Steel 347/347H Pipes Equivalent Grades:

| STANDARD | WERKSTOFF NR. | UNS | JIS | GOST | EN |

| SS 347 | 1.4550 | S34700 | SUS 347 | 08Ch18N12B | X6CrNiNb18-10 |

| SS 347H | 1.4961 | S34709 | SUS 347H | - | X6CrNiNb18-12 |

347 stainless steel tubing Chemical Composition:

| Grade | C | Mn | Si | P | S | Cr | Cb | Ni | Fe |

| SS 347 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 20.00 | 10xC – 1.10 | 9.00 - 13.00 | 62.74 min |

| SS 347H | 0.04 – 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 19.00 | 8xC – 1.10 | 9.0 -13.0 | 63.72 min |

347 Stainless Steel Pipe Properties:

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

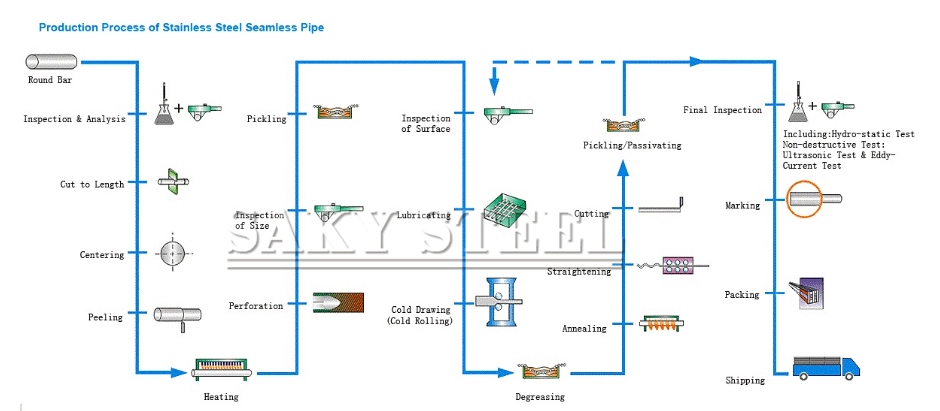

Processes of Stainless Steel Seamless Pipes:

347 Stainless Steel Seamless Pipe Applications:

1.Chemical Processing Equipment – Ideal for heat exchangers, reactors, and piping systems that handle corrosive chemicals at high temperatures.

2.Petrochemical Industry – Used in refinery operations for handling fluids and gases in extreme temperatures.

3.Aerospace Components – Applied in engine parts and exhaust systems requiring heat and oxidation resistance.

4.Power Generation – Utilized in boilers, superheaters, and other high-heat systems for their ability to withstand thermal cycling.

5.Food Processing – Employed in systems where high-temperature steam is used, and resistance to oxidation and corrosion is necessary.

6.Pharmaceutical Equipment – Suitable for piping and tanks exposed to chemicals in sterile environments.

Why Choose Us?

1.With over 20 years of experience, our team of ensures quality in every project.

2.We adhere to stringent quality control processes to ensure every product meets the standards.

3.We leverage the latest technology and innovative solutions to deliver superior products.

4.We offer competitive pricing without compromising on quality, ensuring you get the best value for your investment.

5.We offer a comprehensive range of services to meet all your needs, from initial consultation to final delivery.

6.Our commitment to sustainability and ethical practices ensures that our processes are environmentally friendly.

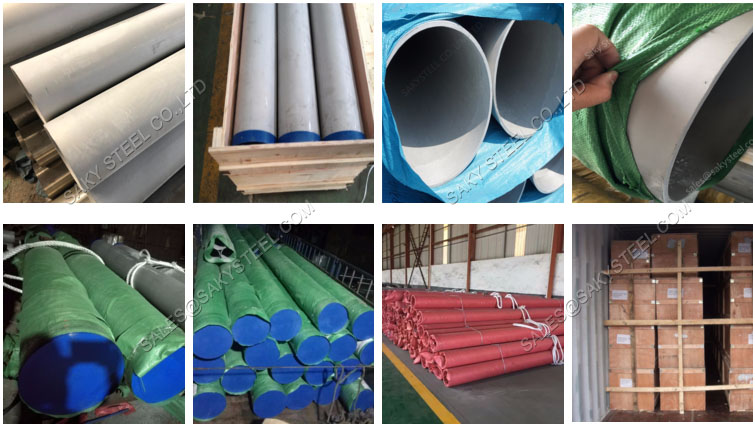

Corrosion-resistant Steel Pipe Packaging:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,