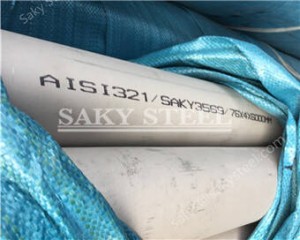

321 Stainless Steel Seamless Pipe

Short Description:

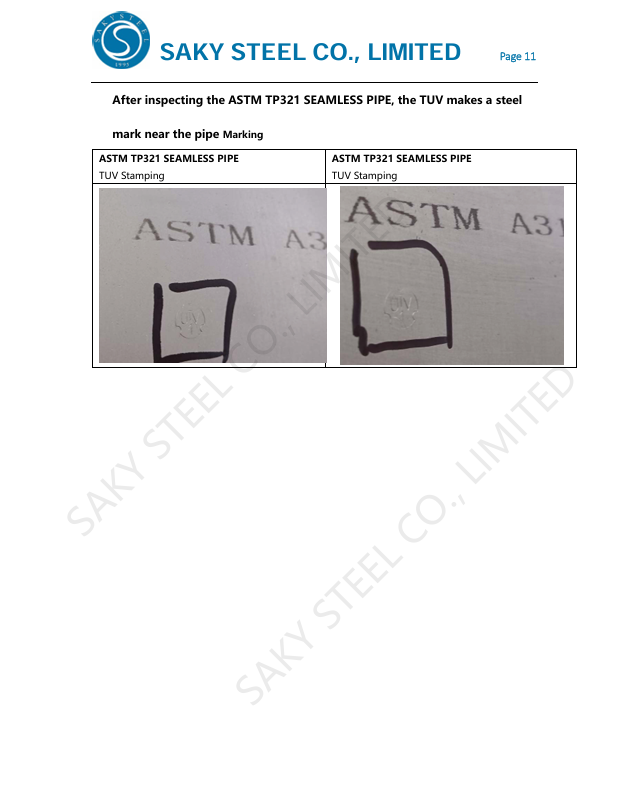

ASTM TP321 SEAMLESS PIPE :

321 stainless steel seamless pipe is a high-performance material widely used in high-temperature environments. 321 stainless steel is based on the 18Cr-8Ni composition with the addition of titanium to enhance its resistance to intergranular corrosion.321 stainless steel seamless pipe performs excellently in high-temperature environments and can be continuously used in the temperature range of 800-1500°F (427-816°C), with a maximum temperature of 1700°F (927°C).Due to the addition of titanium, 321 stainless steel has good resistance to intergranular corrosion, making it suitable for environments where intergranular corrosion might occur under high-temperature conditions.321 stainless steel has high yield strength and tensile strength, along with good ductility and toughness.321 stainless steel can be welded using conventional welding methods, but post-weld annealing may be necessary to restore its corrosion resistance.

Specifications of stainless steel seamless pipe:

| Seamless Pipes & Tubes Size | 1 / 8" NB - 24" NB |

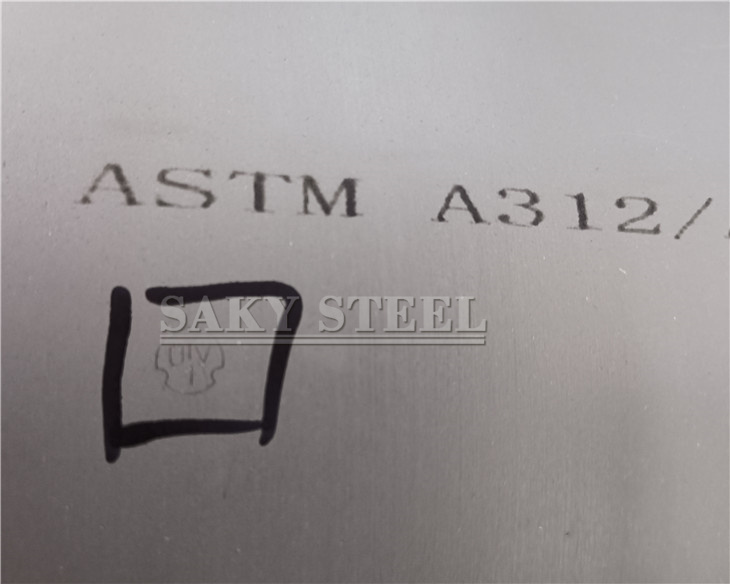

| Specifications | ASTM A/ASME SA213, A249, A269, A312, A358, A790 |

| Standard | ASTM, ASME |

| Grade | 316, 321, 321Ti, 446, 904L, 2205, 2507 |

| Techniques | Hot-rolled, cold-drawn |

| Length | 5.8M,6M & Required Length |

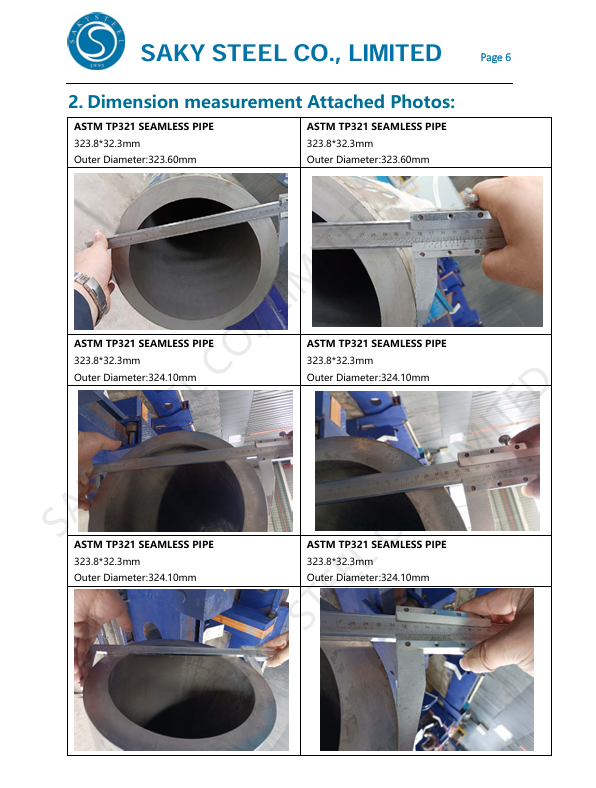

| Outer Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB |

| Thickness | 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Types | Seamless Pipes |

| Form | Round, Square, Rectangle, Hydraulic, Honed Tubes |

| End | Plain End, Beveled End, Treaded |

321/321H Seamless Pipes Equivalent Grades:

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

| SS 321 | 1.4541 | S32100 | SUS 321 | X6CrNiTi18-10 |

| SS 321H | 1.4878 | S32109 | SUS 321H | X12CrNiTi18-9 |

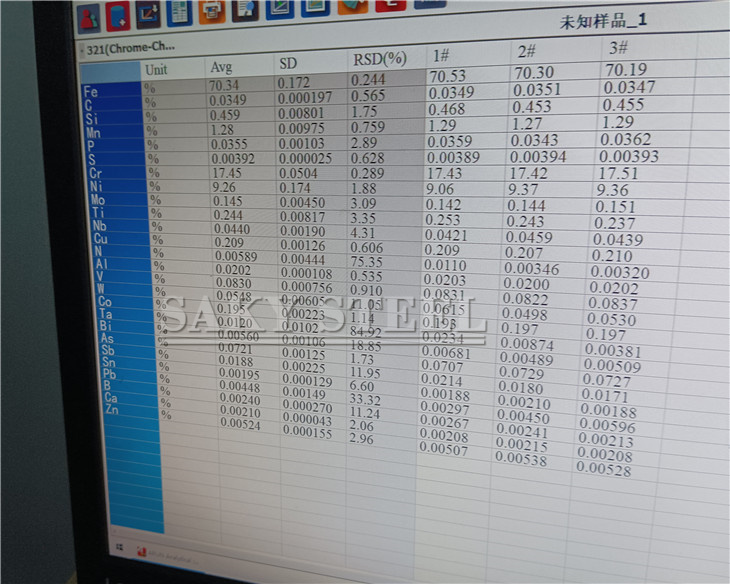

321 / 321H Seamless Pipes Chemical Composition:

| Grade | C | Mn | Si | P | S | Cr | N | Ni | Ti |

| SS 321 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 19.00 | 0.10 max | 9.00 - 12.00 | 5(C+N) – 0.70 max |

| SS 321H | 0.04 – 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 19.00 | 0.10 max | 9.00 – 12.00 | 4(C+N) – 0.70 max |

321 Stainless Steel Seamless Pipe Test:

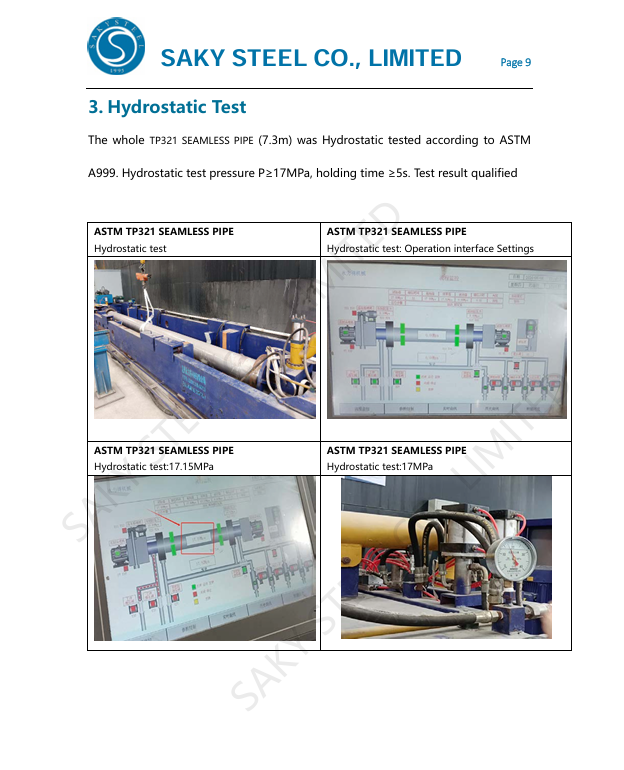

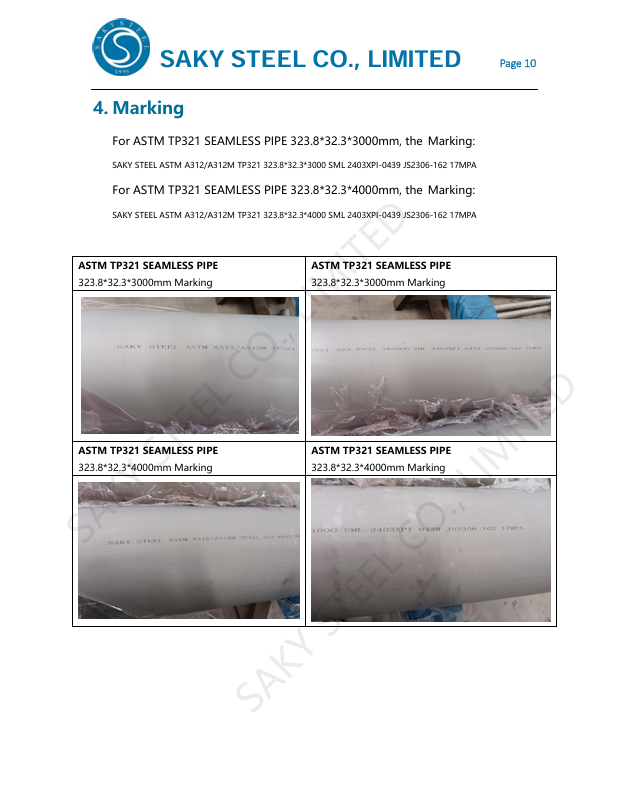

321 SEAMLESS PIPE Hyarostatic Test :

The whole TP321 SEAMLESS PIPE (7.3m) was Hydrostatic tested according to ASTM A999. Hydrostatic test pressure P≥17MPa, holding time ≥5s. Test result qualified

321 SEAMLESS PIPE Hyarostatic Test Report:

Why Choose Us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS TUV report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.

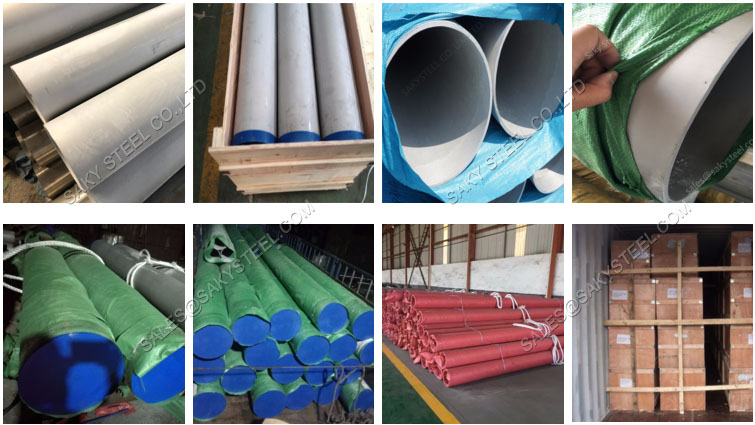

SAKY STEEL'S Packaging:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,