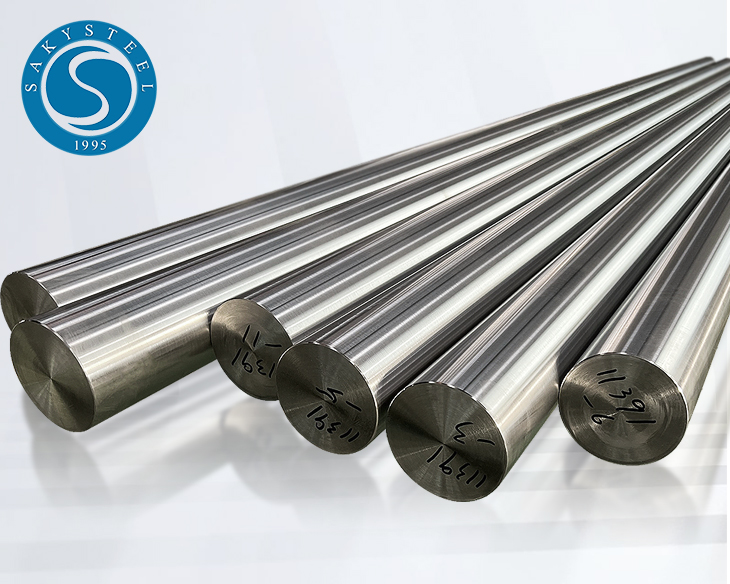

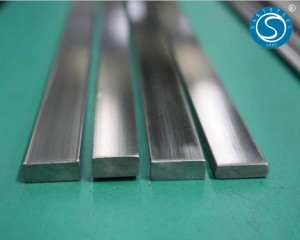

321 321H Stainless Steel bar

Short Description:

Explore the key differences between 321 and 321H stainless steel bars. Learn about their high-temperature resistance, properties, and ideal applications.

321 stainless steel rod:

The 321 stainless steel bar is an austenitic stainless steel alloy containing titanium, which offers excellent resistance to intergranular corrosion even after exposure to temperatures in the chromium carbide precipitation range of 800°F to 1500°F (427°C to 816°C). This makes it ideal for use in high-temperature environments where the metal must maintain its strength and corrosion resistance. Common applications include exhaust manifolds, heat exchangers, and aircraft engine parts. The addition of titanium stabilizes the alloy, preventing carbide formation and ensuring long-term durability.

Specifications Of SS 321 round bar:

| Grade | 304,314,316,321,321H etc. |

| Standard | ASTM A276 |

| Length | 1-12m |

| Diameter | 4.00 mm to 500 mm |

| Condition | Cold Drawn & Polished Cold Drawn, Peeled & Forged |

| Surface Finish | Black, Bright, Polished, Rough Turned, NO.4 Finish, Matt Finish |

| Form | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forged Etc. |

| End | Plain End, Beveled End |

| Mill Test Certificate | EN 10204 3.1 or EN 10204 3.2 |

Stainless Steel 321/321H Bar Equivalent Grades:

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

| SS 321 | 1.4541 | S32100 | SUS 321 | X6CrNiTi18-10 |

| SS 321H | 1.4878 | S32109 | SUS 321H | X12CrNiTi18-9 |

SS 321 / 321H Bar Chemical Composition:

| Grade | C | Mn | Si | P | S | Cr | N | Ni | Ti |

| SS 321 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 19.00 | 0.10 max | 9.00 - 12.00 | 5(C+N) – 0.70 max |

| SS 321H | 0.04 – 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 19.00 | 0.10 max | 9.00 – 12.00 | 4(C+N) – 0.70 max |

321 stainless steel bar applications

1.Aerospace: Components such as exhaust systems, manifolds, and turbine engine parts where exposure to high temperatures and corrosive environments is frequent.

2.Chemical Processing: Equipment like heat exchangers, chemical reactors, and storage tanks, where resistance to acidic and corrosive substances is essential.

3.Petroleum Refining: Piping, heat exchangers, and other equipment exposed to high-temperature petroleum and petrochemical processes.

4.Power Generation: Boilers, pressure vessels, and other components in power plants that operate under high heat and pressure.

5.Automotive: Exhaust systems, mufflers, and catalytic converters that require resistance to high temperatures and oxidation.

6.Food Processing: Equipment that must endure repeated cycles of heating and cooling, while maintaining hygienic conditions, such as in dairy and food processing machinery.

Why Choose us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS TUV report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.

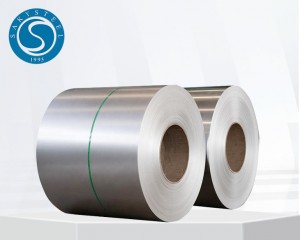

SS 321 round bar Packing:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,