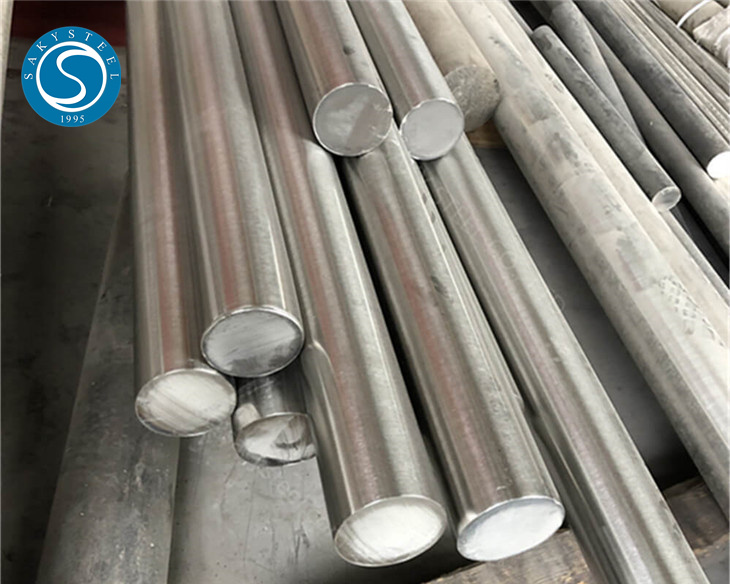

317/317L Stainless Steel Bar

Short Description:

317L stainless steel bar, corrosion-resistant and suitable for high-temperature environments. Discover our 317L stainless steel bar suppliers and prices now.

317 Stainless Steel Bars:

317 and 317L stainless steel bars are high-alloy austenitic stainless steels with higher levels of chromium, nickel, and molybdenum compared to standard grades like 304 and 316. These enhancements provide superior corrosion resistance, particularly in acidic environments.317 and 317L stainless steel bars are high-alloy austenitic stainless steels with higher levels of chromium, nickel, and molybdenum compared to standard grades like 304 and 316. These enhancements provide superior corrosion resistance, particularly in acidic environments.317 and 317L stainless steel bars are premium materials ideal for demanding applications requiring superior corrosion resistance, strength, and durability.

Specifications Of 317L Stainless Steel Round Bar:

| Grade | 317,317L. |

| Standard | ASTM A276/A479 |

| Surface | hot rolled pickled ,polished |

| Technology | Hot Rolled , Forged,Cold down |

| Length | 1 to 12 Meters |

| Mill Test Certificate | EN 10204 3.1 or EN 10204 3.2 |

| Type | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging ,Etc. |

Chemical equipment stainless steel bar 317/317L:

| Grade | C | Mn | P | S | Si | Cr | Mo | Ni |

| 317 | 0.08 | 2.0 | 0.040 | 0.030 | 1.0 | 18.0-20.0 | 3.0-4.0 | 11.0-14.0 |

| 317L | 0.035 | 2.0 | 0.040 | 0.030 | 1.0 | 18.0-20.0 | 3.0-4.0 | 11.0-15.0 |

ASTM A276 317/317L Bar Mechanical properties :

| Density | Melting Point | Tensile Strength ksi[MPa] | Yiled Strengtu ksi[MPa] | Elongation % |

| 7.9 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 |

317/317L Stainless Steel Bar Features

• Corrosion Resistance: Both 317 and 317L stainless steels offer exceptional resistance to pitting, crevice corrosion, and general corrosion in aggressive environments, including those containing sulfuric, acetic, formic, and citric acids.

• High Strength and Durability: These alloys maintain their strength and toughness even at elevated temperatures, making them suitable for high-stress applications.

• Low Carbon Content in 317L: The "L" in 317L stands for low carbon content (maximum of 0.03%), which helps in minimizing carbide precipitation during welding, thereby preserving the alloy's corrosion resistance in welded structures.

Why Choose us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS TUV report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.From raw material procurement to final delivery, the entire process is identifiable and traceable.

Corrosion-resistant stainless steel bar 317L Packing:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,