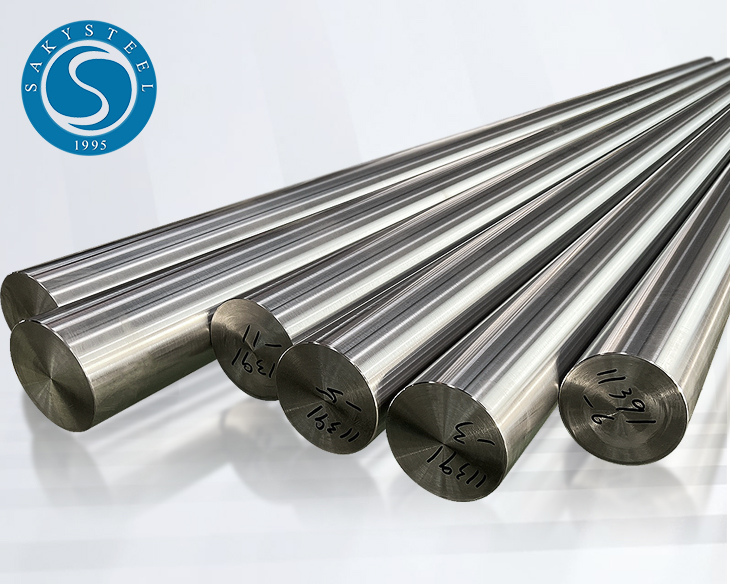

310S Stainless Steel Bar

Short Description:

310S stainless steel is a high-alloy stainless steel that is known for its excellent high-temperature properties. With a high content of chromium (24-26%) and nickel (19-22%), 310S stainless steel offers superior corrosion resistance and high temperature resistance compared to lower alloyed grades.

Stainless Steel 310s Bars:

The 310S can withstand continuous exposure to temperatures up to 2100°F (1150°C), and for intermittent service, it can handle even higher temperatures. This makes it perfect for applications where the material will be exposed to extreme heat.With its high chromium and nickel content, 310S offers excellent resistance to a wide range of corrosive environments, surpassing that of many other stainless steel grades.It is highly resistant to oxidation, even under mildly cyclic conditions, which is a critical property for materials exposed to the atmosphere at high temperatures.Unlike many other materials, 310S maintains its strength at high temperatures, which is essential for the structural components in high-temperature environments.

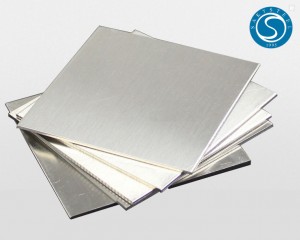

Specifications Of 310s Steel Bar:

| Grade | 310,310s,316 etc. |

| Standard | ASTM A276 / A479 |

| Surface | hot rolled pickled ,polished |

| Technology | Hot Rolled / Cold Rolled / Hot Forging / Rolling / Machining |

| Length | 1 to 6 Meters |

| Type | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

| Raw Materail | POSCO, Baosteel, TISCO,Saky Steel, Outokumpu |

Features & Benefits:

• 310S stainless steel can withstand continuous high temperatures up to 2100°F (approximately 1150°C) and performs well even under intermittent high temperatures. This makes it an ideal choice for applications requiring high-temperature materials.

• The high levels of chromium and nickel provide excellent resistance to corrosion, especially in oxidative environments. 310S stainless steel is resistant to a variety of chemical media, including some acids and bases.

• Despite being a high-alloy material, 310S can be processed using various welding methods, offering strong adaptability.

•At high temperatures, 310S exhibits outstanding resistance to oxidation, even under cyclic conditions, which is crucial for applications in high-temperature environments.

Equivalent Grades of Stainless Steel 310S Bars:

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | EN |

| SS 310S | 1.4845 | S31008 | SUS 310S | 310S16 | 20Ch23N18 | X8CrNi25-21 |

Chemical Composition Of 310S Stainless Steel Bar:

| Grade | C | Mn | P | S | Si | Cr | Ni |

| 310S | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 24.0-26.0 | 19.0-22.0 |

A479 310s Round Bar Mechanical properties :

| Grade | Tensile Strength ksi[MPa] | Yiled Strengtu ksi[MPa] | Elongation % |

| 310S | 75[515] | 30[205] | 30 |

310s Round Bar Test Report :

Why Choose us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS TUV report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.

What are the welding methods of 310S Stainless Bar?

310S is a commonly used stainless steel material, often utilized in applications that require high temperature and corrosion resistance, such as in the chemical, refining, and petroleum extraction industries.To weld 310S stainless steel bars, one can utilize methods such as Gas Tungsten Arc Welding (GTAW/TIG), Shielded Metal Arc Welding (SMAW), or Gas Metal Arc Welding (GMAW/MIG), and choose welding wire/rods matching 310S, such as ER310, ensuring chemical composition and performance compatibility.

Our Clients

Feedbacks From Our Clients

400 series stainless steel rods have several notable advantages, making them favored in various applications.400 series stainless steel rods typically exhibit excellent corrosion resistance, making them resistant to oxidation, acids, salts, and other corrosive substances, suitable for harsh environments.These stainless steel rods are often free-machining, demonstrating excellent machinability. This feature makes them easy to cut, shape, and process.400 series stainless steel rods perform well in terms of strength and hardness, suitable for applications requiring high strength and wear resistance, such as the manufacturing of mechanical components.

Packing:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,