304 Stainless Steel Tube Welding

Short Description:

| Specifications of stainless steel welded pipe: |

Seamless Pipes & Tubes Size : 1 / 8″ NB – 24″ NB

Specifications : ASTM A/ASME A249, A268, A269, A270, A312, A790

Grade: 304, 304L, 316, 316L, 321, 409L

Length :5.8M,6M & Required Length

Outer Diameter : 6.00 mm OD up to 1500 mm OD

Thickness : 0.3mm – 20mm,

Schedule : SCH 5, SCH10, SCH 40, SCH 80, SCH 80S

Surface Finish : Mill Finish,Polishing(180#,180# hairline,240# hairline,400#,600#),Mirror etc

Types : Welded, EFW, ERW

Form : Round, Square, Rectangle

End : Plain End, Beveled End

| Stainless Steel 304/304L Welded Pipes Equivalent Grades: |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

| SS 304L | 1.4306 / 1.4307 | S30403 | SUS 304L | 3304S11 | 03Х18Н11 | Z3CN18‐10 | X2CrNi18-9 / X2CrNi19-11 |

| SS 304 / 304L Welded Pipes Chemical Composition and Mechanical properties: |

| Grade | C | Mn | Si | P | S | Cr | Ni |

| SS 304 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | 8 – 11 |

| SS 304L | 0.035 max | 2 max | 1.0 max | 0.045 max | 0.03 max | 18 – 20 | 8 – 13 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

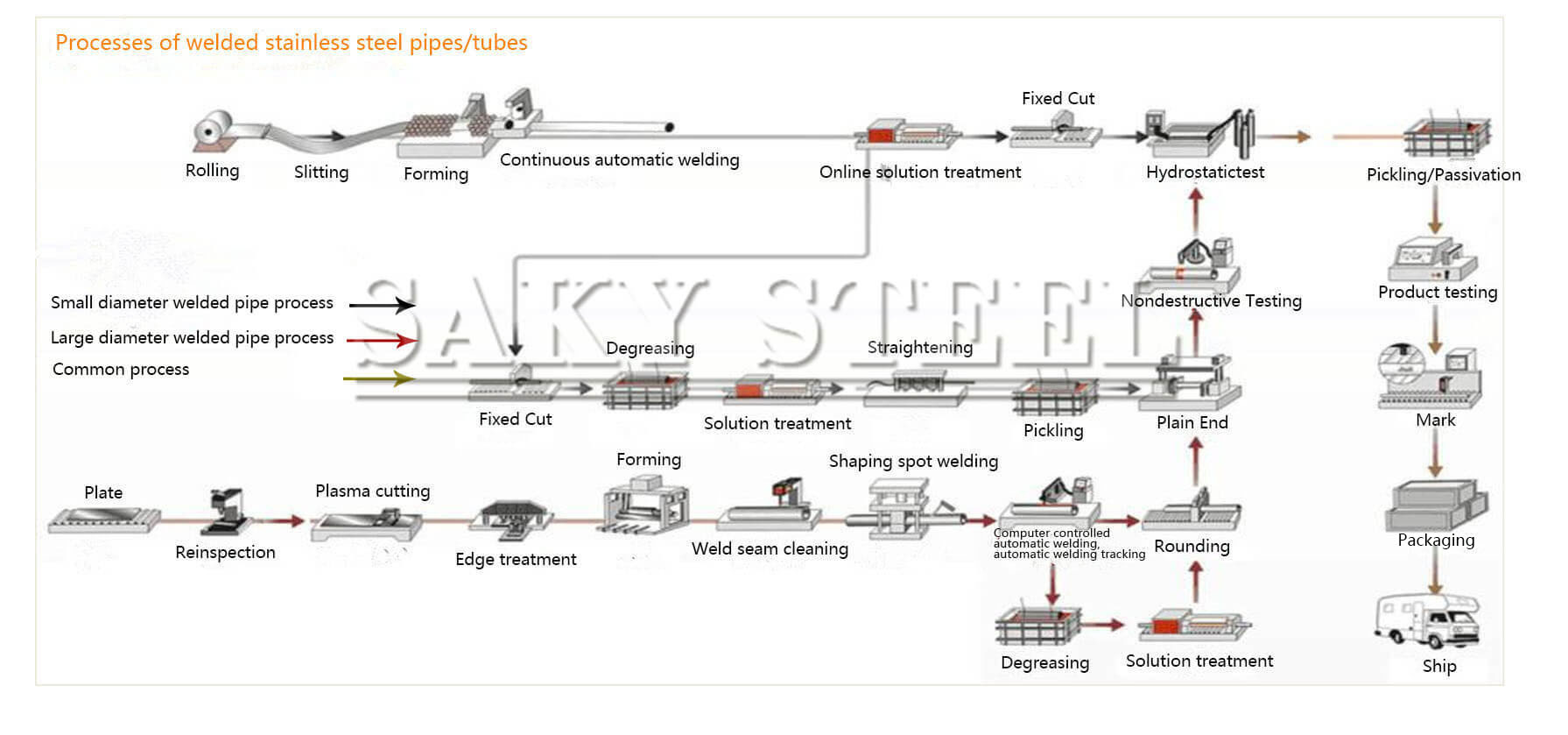

| Processes of welded stainless steel pipes/tubes : |

| Surface Finish Options: |

We offer two types of brushing directions to meet different decorative and functional needs:

Straight Hairline (Longitudinal Brushing):

The grain runs along the length of the tube, creating a smooth and continuous visual effect. Ideal for elevator decoration, architectural handrails, furniture tubing, and other high-end applications.

Cross Hairline (Transverse Brushing):

The grain encircles the tube’s circumference, offering a unique appearance for end-cap fittings, structural parts, and custom decorative designs.

|

|

| Cross Hairline | Straight Hairline |

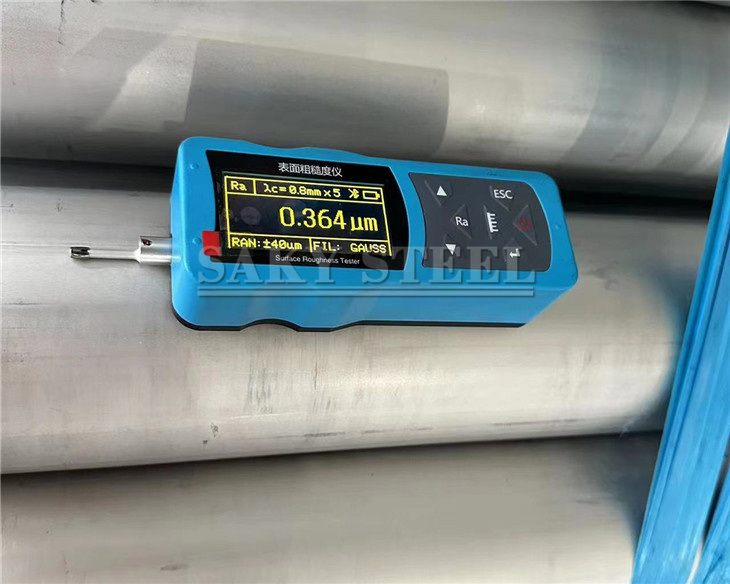

| 304 Stainless Steel Tubing Weld Roughness test |

At SAKY STEEL we perform strict roughness testing on stainless steel pipes to ensure a smooth and consistent surface that meets international standards. Pipe roughness is a key factor that affects flow efficiency corrosion resistance and overall performance in critical applications.

We use precision instruments to measure surface roughness values ensuring all pipes meet customer requirements for smoothness and finish. Our pipes are ideal for chemical food processing marine and structural industries where surface quality is essential.

|

|

| 304 Stainless Steel Welded Tube Surface Test |

The surface finish of stainless steel pipes is critical for performance and appearance. At SAKY STEEL we strictly control surface quality through advanced inspection processes. The image shows a clear comparison between bad surface pipes with visible defects and our good surface pipes with smooth and uniform finish.

Our stainless steel pipes are free from cracks pits scratches and welding marks ensuring excellent corrosion resistance and reliability. These pipes are widely used in chemical marine and structural applications where surface integrity matters.

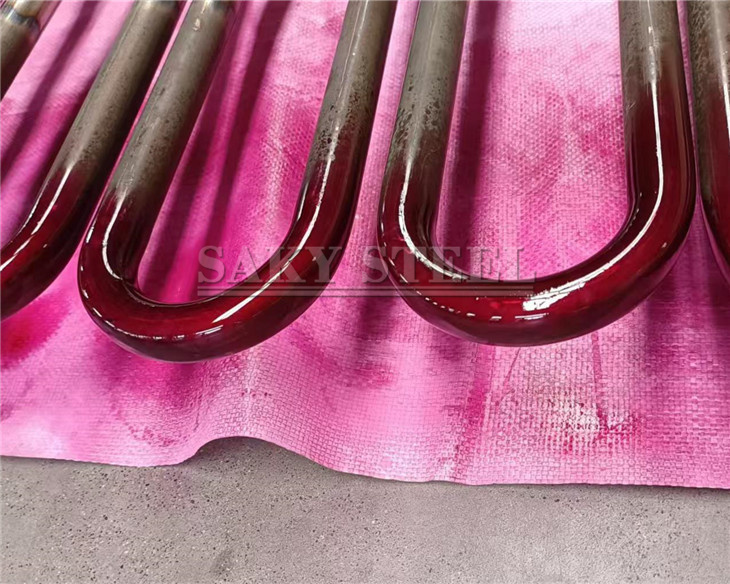

| 304 Stainless Steel Welded Pipe PT Test |

SAKY STEEL performs penetrant testing PT on stainless steel pipes and components as part of our strict quality control process. PT is a non destructive testing method used to detect surface defects such as cracks porosity and inclusions that are not visible to the naked eye.

Our trained inspectors apply high quality penetrant and developer materials to ensure accurate and reliable results. All PT procedures follow international standards and customer specifications guaranteeing product safety and performance.

|

|

| Weld Seam Inspection of 304 Stainless Steel Welded Pipe |

Stainless steel pipe weld seam inspection ensures that all welded joints meet the required quality and safety standards. The inspection process focuses on detecting surface and internal defects such as cracks, porosity, slag inclusions, lack of fusion, and incomplete penetration. Common methods include visual inspection, dye penetrant testing, ultrasonic testing, and radiographic testing. Each method is selected based on pipe material, wall thickness, and service conditions. All inspections are carried out in accordance with international standards such as ASME, ASTM, and ISO to guarantee the integrity and performance of the welded pipes.

|

|

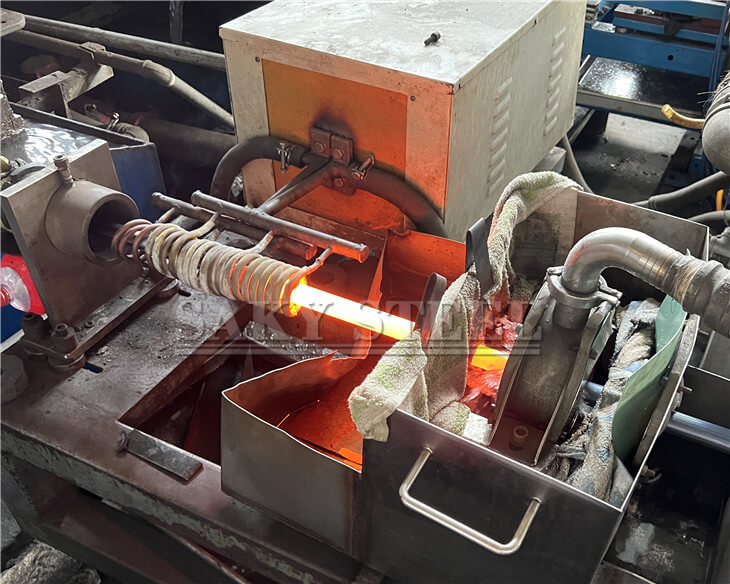

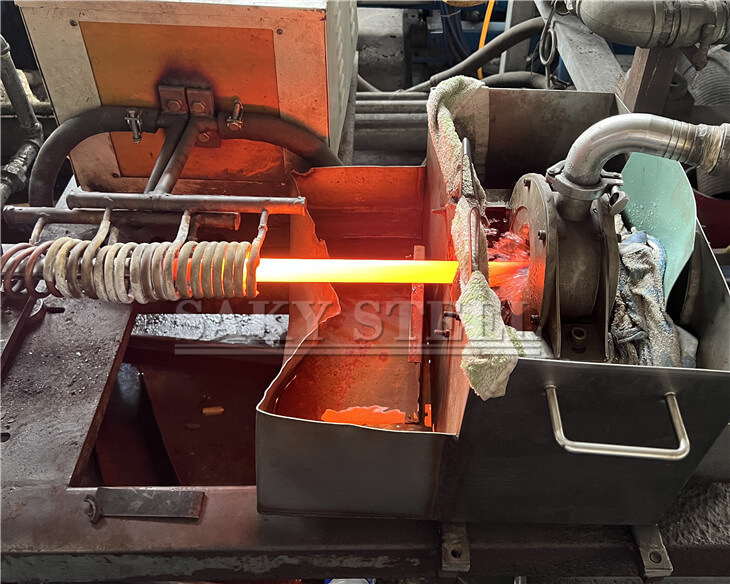

| In-line Solution Annealing of Stainless Steel Welded Pipe |

In-line solution annealing of stainless steel pipe is a continuous heat treatment process applied during production to achieve a uniform austenitic microstructure and enhance corrosion resistance. The pipe is heated to the specified solution annealing temperature, typically between 1000°C and 1150°C, and then rapidly cooled, often using water quenching or forced air cooling. This process dissolves carbide precipitates and prevents intergranular corrosion, ensuring the mechanical properties and surface quality meet international standards. In-line solution annealing improves production efficiency while maintaining consistent product performance.

|

|

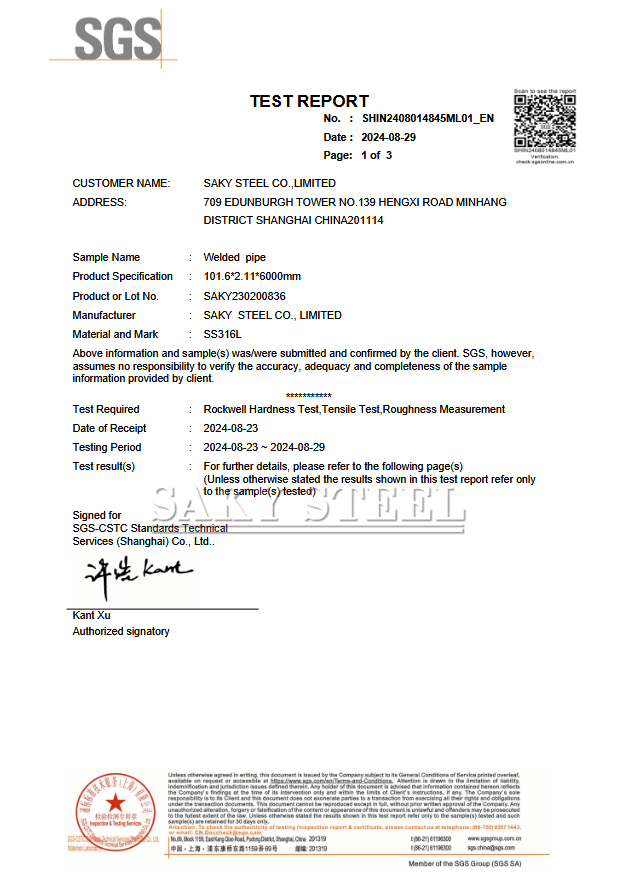

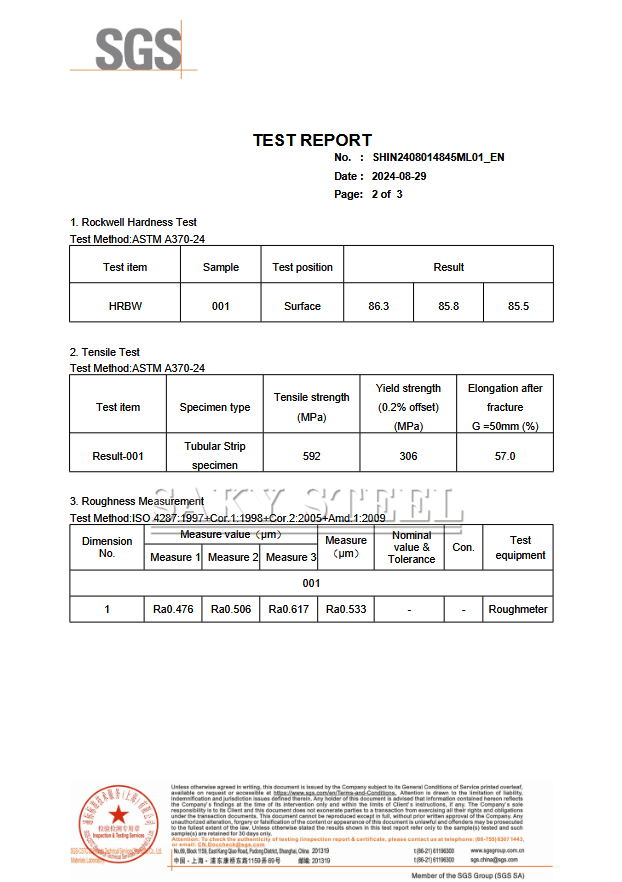

| Welded pipe Test Report |

The mechanical properties of the product have been tested in accordance with ASTM A370 Standard Test Methods and Definitions for Mechanical Testing of Steel Products. All test results, including tensile strength, yield strength, elongation, and hardness, comply with the specified requirements and are documented as part of this certificate to ensure conformity to the applicable standards and customer specifications.

|

|

|

| Why Choose Us |

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. e guarantee to give a response within 24hours(usually in the same hour)

5. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

| SAKY STEEL’S Quality Assurance (including both Destructive and Non-Destructive) |

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Large-scale test

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Flaring Testing

8. Water-Jet Test

9. Penetrant Test

10. X-ray test

11. Intergranular Corrosion Testing

12. Impact analysis

13. Metallography Experimental Test

| SAKY STEEL’S Packaging: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,

Applications:

1. Auto parts, Medical equipment

2. Heat Exchanger, Food industry

3. Agriculture,Electricity, Chemical

4. Coal chemical; Oil and gas exploration

5. Petroleum refining, Natural gas; Instrumentation