303 Stainless Steel Flat Bar

Short Description:

Sakysteel is Stainless Flat Bar manufacturer and suppliers in china, specialized in the research, development and production of 303 Stainless Steel Flat Bar.

| C% | Si% | Mn% | P% | S% | Cr% | Ni% | N% | Mo% | Ti% |

| <0.15 | <1.0 | <2.0 | <0.20 | <0.15 | 17.0-19.0 | 8.0-10.0 | – | – | – |

| Specifications of 303 Stainless Steel Flat Bar: |

| Standard | ASTM A276, A484, A479, A580, A582, JIS G4303, JIS G4311,DIN 1654-5,DIN 17440,KS D3706,GB/T 1220 |

| Material | 201,202,205,XM-19 etc. 301,303,304,304L,304H,309S,310S,314,316,316L,316Ti,317,321,321H,329,330,348 etc. 409,410,416,420,430,430F,431,440 2205,2507,S31803,2209,630,631,15-5PH,17-4PH,17-7PH,904L,F51,F55,253MA etc. |

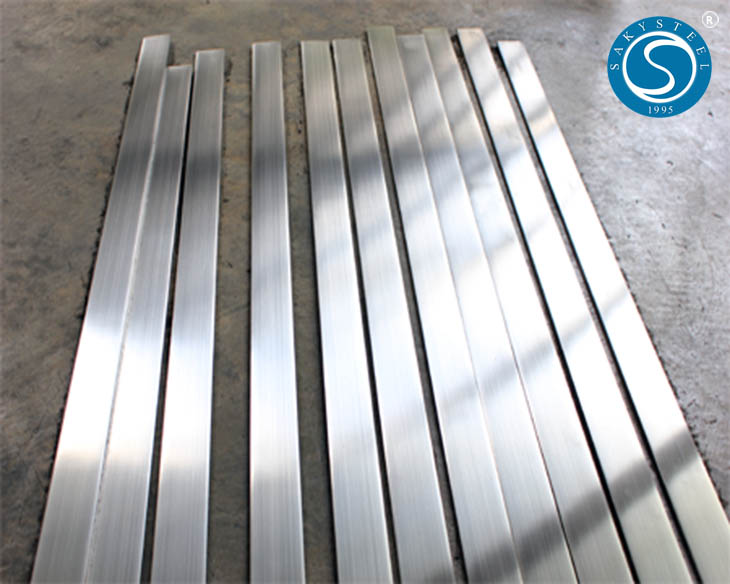

| Surface | Pickled,Peeled,Black,Sand Blast,Bright,Mill,Mirror,Hairline etc |

| Technology | Hot Rolled,Welded,Bend |

| Specifications | 20*3mm -100*10mm or as required |

| Tolerance | +-2% |

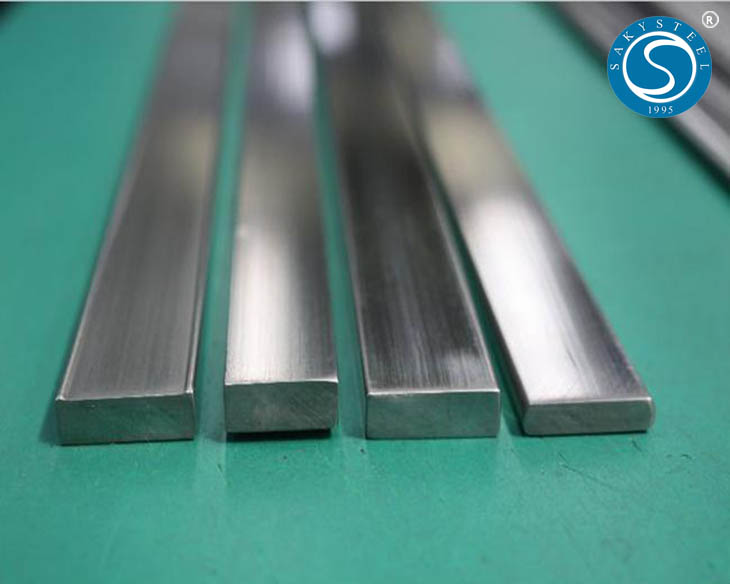

| 316 Stainless Steel Flat Bar products from sakysteel: |

pickled stainless steel flat bar pickled stainless steel flat bar |

Sample_Logo Right Sample_Logo Right |

| Application of 303 Stainless Steel Flat Bar |

1.Domestic:cutlery,sinks,saucepans,washing machine drums,microwave open liners ,razor blades

2.Transourt:exhaust systems,car trim/grilles,road tankers,ship containers,ships chemical tankers

3.Oil and Gas:platform accommodation,cable trays

4.Medical:Surgical instruments,surgical implants,MRI scanners.

5.Food and Drink:Catering equipment,brewing,distilling,food processing

6.Water:Water and sewage treatment,water tubing,hot water tanks

7.General:springs,fasteners(bolts,nut andwashers),wire

8.Chemical /Pharmaceutical:pressure vessels,process piping

9.Architectural/Civil Engineering:cladding,handrails,door and window fittings,street furniture,structural,sections,reinforce ment bar,lighting columns,lintels,masonry supports

| Chemical composition of Stainless Steel Flat Bar: |

| Austenite Ferrite Stainless Steel |

329J1 | 0Cr26Ni5Mo2 | <0.08 | 23.00-28.00 | 3.00-6.00 | <1.50 | <0.035 | <0.030 | 1.00-3.00 | <1.00 | - | 2) |

| 1Cr18Ni11Si4AlTi | 0.10-0.18 | 17.50-19.50 | 10.–120.. | <0.80 | <0.035 | <0.030 | - | 3.40-4.00 | - | Al 0.10-0.30; Ti 0.40-0.70 | ||

| 00Cr18Ni5MoSi2 | <0.030 | 18.00-19.50 | 4.50-5.50 | 1.00-2.00 | <0.035 | <0.030 | 2.50-3.00 | 1.30-2.00 | - | - | ||

| Ferrite Stainless Steel | 405 | 0Cr13Al | <0.08 | 11.50-14.50 | 3) | <1.00 | <0.035 | <0.030 | - | <1.00 | - | Al 0.10-0.30 |

| 410L | 00Cr12 | <0.030 | 11.00-13.00 | 3) | <1.00 | <0.035 | <0.030 | - | <1.00 | - | - | |

| 430 | 1Cr17 | <0.12 | 16.00-18.00 | 3) | <1.25 | <0.035 | <0.030 | - | <0.75 | - | - | |

| 430F | Y1Cr17 | <0.12 | 16.00-18.00 | 3) | <1.00 | <0.035 | <0.15 | 1) | <1.00 | - | - | |

| 434 | 1Cr17Mo | <0.12 | 16.00-18.00 | 3) | <1.00 | <0.035 | <0.030 | 0.75-1.25 | <1.00 | - | - | |

| 447J1 | 00Cr30Mo2 | <0.010 | 28.50-32.00 | - | <0.40 | <0.035 | <0.030 | 1.50-2.50 | <0.40 | <0.015 | - | |

| XM27 | 00Cr27Mo | <0.010 | 25.00-27.50 | - | <0.40 | <0.035 | <0.030 | 0.75-1.50 | <0.40 | <0.015 | - |

| Martensite stainless steel | 403 | 1Cr12 | <0.15 | 11.50-13.00 | 3) | <1.00 | <0.035 | <0.030 | - | <0.50 | - | - |

| 410 | 1Cr13 | <0.15 | 11.50-13.50 | 3) | <1.00 | <0.035 | <0.030 | - | <1.00 | - | - | |

| 405 | 0Cr13 | <0.08 | 11.50-13.50 | 3) | <1.00 | <0.035 | <0.030 | - | <1.00 | - | - | |

| 416 | Y1Cr13 | <0.15 | 12.00-14.00 | 3) | <1.25 | <0.035 | <0.15 | 1) | <1.00 | - | - | |

| 410J1 | 1Cr13Mo | <0.08-0.18 | 11.50-14.00 | 3) | <1.00 | <0.035 | <0.030 | 0.30-0.60 | <0.60 | - | - | |

| 420J1 | 2Cr13 | 0.16-0.25 | 12.00-14.00 | 3) | <1.00 | <0.035 | <0.030 | - | <1.00 | - | - | |

| 420J2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | 3) | <1.00 | <0.035 | <0.030 | - | <1.00 | - | - | |

| 420F | Y3Cr13 | 0.26-0.40 | 12.00-14.00 | 3) | <1.25 | <0.035 | <0.15 | 1) | <1.00 | - | - | |

| 3Cr13Mo | 0.28-0.35 | 12.00-14.00 | 3) | <1.00 | <0.035 | <0.030 | 0.50-1.00 | <0.80 | - | - | ||

| 4Cr13 | 0.36-0.45 | 12.00-14.00 |