18 Years Factory Stainless Steel Flat Rod - Alloy Wire – Saky Steel

18 Years Factory Stainless Steel Flat Rod - Alloy Wire – Saky Steel Detail:

sakysteel is a stockholder and supplier of Alloy products:

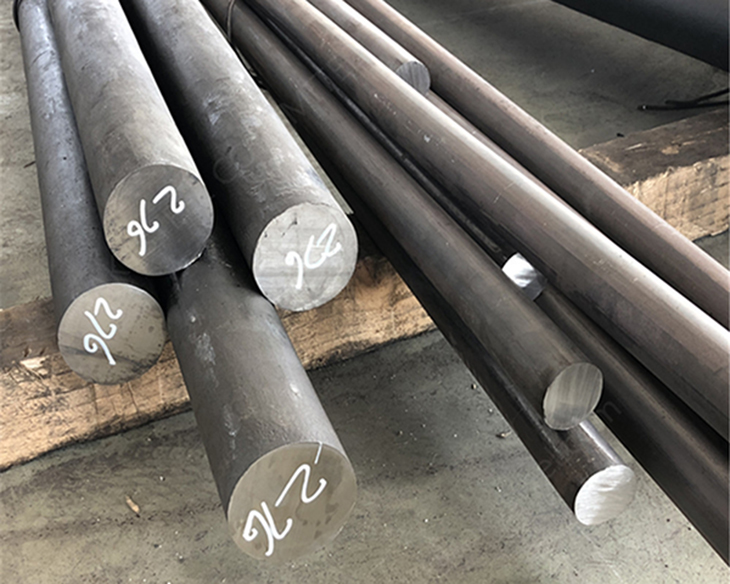

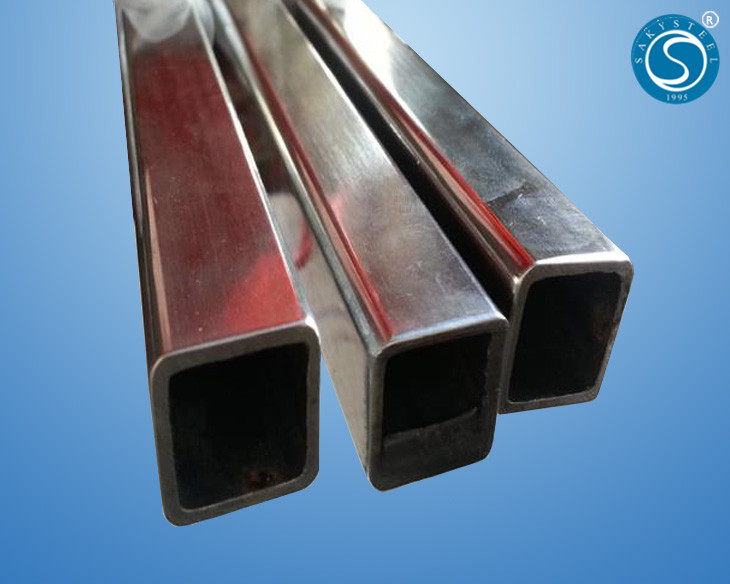

· Pipe (seamless & welded)

· Bar (round, angle,flat,square,hexagonal & channel)

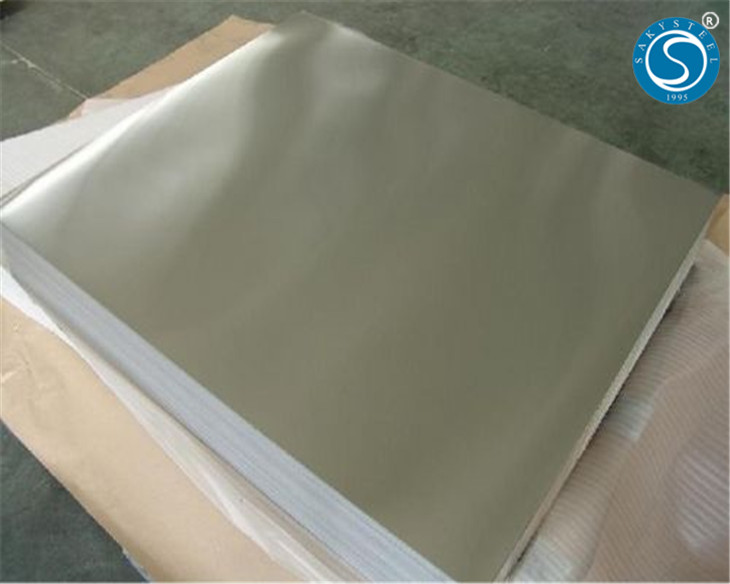

· Plate & sheet & coil & strip

· Wire

Alloy 200 Equivalents: UNS N02200/Nickel 200/Werkstoff 2.4066

Applications Alloy 200:

Alloy 200 is a 99.6% pure nickel alloy which is used extensively in the (petro)chemical industry

| Chemical analysis Alloy 200: | Alloy 200 ASTM standards: |

| Nickel – 99,0% min. | Bar/Billet – B160 |

| Copper – 0,25% max. | Forgings/Flanges – B564 |

| Manganese – 0,35% max. | Seamless Tubing – B163 |

| Carbon – 0,15% max. | Welded Tubing – B730 |

| Silicon – 0,35% max. | Seamless Pipe – B163 |

| Sulfur – 0,01% max. | Welded Pipe – B725 |

| Plate – B162 | |

| Density Alloy 200: 8,89 | Buttweld fittings – B366 |

Alloy 201 Equivalents: UNS N02201/Nickel 201/Werkstoff 2.4068

Applications Alloy 201:

Alloy 201 is a commercially pure (99.6%) Nickel alloy very similar to Alloy 200 but with a lower carbon content to so it can be used at higher temperatures. The lower carbon content also reduces hardness, making Alloy 201 particularly suitable for cold-formed items.

| Chemical analysis Alloy 201: | Alloy 201 ASTM standards: |

| Nickel – 99,0% min. | Bar/Billet – B160 |

| Copper – 0,25% max. | Forgings/Flanges – B564 |

| Manganese – 0,35% max. | Seamless Tubing – B163 |

| Carbon – 0,02% max. | Welded Tubing – B730 |

| Silicon – 0,35% max. | Seamless Pipe – B163 |

| Sulfur – 0,01% max. | Welded Pipe – B725 |

| Plate – B162 | |

| Density Alloy 201: 8,89 | Buttweld fittings – B366 |

Alloy 400 Equivalents: UNS N04400/Monel 400/Werkstoff 2.4360

Applications Alloy 400:

Alloy 400 is a nickel-copper alloy with high strength and excellent corrosion resistance in a range of media including sea water, hydrofluoric acid, sulfuric acid, and alkalies. Used for marine engineering, chemical and hydrocarbon processing equipment, valves, pumps, shafts, fittings, fasteners, and heat exchangers.

| Chemical analysis Alloy 400: | Alloy 400 ASTM standards: |

| Nickel – 63,0% min. (incl. cobalt) | Bar/Billet – B164 |

| Copper -28,0-34,0% max. | Forgings/Flanges – B564 |

| Iron – 2,5% max. | Seamless Tubing – B163 |

| Manganese – 2,0% max. | Welded Tubing – B730 |

| Carbon – 0,3% max. | Seamless Pipe – B165 |

| Silicon – 0,5% max. | Welded Pipe – B725 |

| Sulfur – 0,024% max. | Plate – B127 |

| Density Alloy 400: 8,83 | Buttweld fittings – B366 |

Alloy 600 Equivalents: UNS N06600/Inconel 600/Werkstoff 2.4816

Applications Alloy 600:

Alloy 600 is a nickel-chromium alloy with good oxidation resistance at high temperatures and resistance to chloride-ion stress-corrosion cracking, corrosion by high-purity water, and caustic corrosion. Used for furnace components, in chemical and food processing, in nuclear engineering, and for sparking electrodes.

| Chemical analysis Alloy 600: | Alloy 600 ASTM standards: |

| Nickel – 62,0% min. (incl. cobalt) | Bar/Billet – B166 |

| Chromium – 14.0-17.0% | Forgings/Flanges – B564 |

| Iron – 6.0-10.0% | Seamless Tubing – B163 |

| Manganese – 1,0% max. | Welded Tubing – B516 |

| Carbon – 0,15% max. | Seamless Pipe – B167 |

| Silicon – 0,5% max. | Welded Pipe – B517 |

| Sulfur – 0,015% max. | Plate – B168 |

| Copper -0,5% max. | Buttweld fittings – B366 |

| Density Alloy 600: 8,42 |

Alloy 625 Equivalents: Inconel 625/UNS N06625/Werkstoff 2.4856

Applications Alloy 625:

Alloy 625 is a nickel-chromium-molybdenum alloy with niobium added. This provides high strength without a strengthening heat treatment. The alloy resists a wide range of severely corrosive environments and is especially resistant to pitting and crevice corrosion. Used in chemical processing, aerospace and marine engineering, pollution-control equipment, and nuclear reactors.

| Chemical analysis Alloy 625: | Alloy 625 ASTM standards: |

| Nickel – 58,0% min. | Bar/Billet – B166 |

| Chromium – 20.0-23.0% | Forgings/Flanges – B564 |

| Iron – 5.0% | Seamless Tubing – B163 |

| Molybdenum 8,0-10,0% | Welded Tubing – B516 |

| Niobium 3,15-4,15% | Seamless Pipe – B167 |

| Manganese – 0,5% max. | Welded Pipe – B517 |

| Carbon – 0,1% max. | Plate – B168 |

| Silicon – 0,5% max. | Buttweld fittings – B366 |

| Phosphorous: 0,015% max. | |

| Sulfur – 0,015% max. | |

| Aluminium: 0,4% max. | |

| Titanium: 0,4% max. | |

| Cobalt: 1,0% max. | Density Alloy 625 625: 8,44 |

Alloy 825 Equivalents: Incoloy 825/UNS N08825/Werkstoff 2.4858

Applications Alloy 825:

Alloy 825 is a nickel-iron-chromium alloy with molybdenum and copper added to it. It has excellent resistance to both reducing and oxidizing acids, to stress-corrosion cracking, and to localized attack such as pitting and crevice corrosion. The alloy is especially resistant to sulfuric and phosphoric acids. Used for chemical processing, pollution-control equipment, oil and gas well piping, nuclear fuel reprocessing, acid production, and pickling equipment.

Alloy C276 – UNS N10276

Applications Alloy C276:

Alloy C276 has a very good resistance to a variety of chemical process environments such as hot contaminated organic and inorganic media, chlorine, formic and acetic acids, acetic anhydride, seawater and brine solutions and strong oxidizers such as ferric and cupric chlorides. Alloy C276 has excellent resistance to pitting and to stress-corrosion cracking but it is also used in flue gas desulfurization systems for sulfur compounds and chloride ions encounted in most scrubbers. It is also one of the few materials that withstands the corrosive effects of wet chlorine gas, hypochlorite, and chlorine dioxide.

| Chemical analysis Alloy C276: | Alloy C276 ASTM standards: |

| Nickel – balance | Bar/Billet – B574 |

| Chromium – 14,5-16,5% | Forgings/Flanges – B564 |

| Iron – 4,0-7,0% | Seamless Tubing – B622 |

| Molybdenum – 15,0-17,0% | Welded Tubing – B626 |

| Tungsten – 3,0-4,5% | Seamless Pipe – B622 |

| Cobalt – 2,5% max. | Welded Pipe – B619 |

| Manganese – 1,0% max. | Plate – B575 |

| Carbon – 0,01% max. | Buttweld fittings – B366 |

| Silicon – 0,08% max. | |

| Sulfur – 0,03% max. | |

| Vanadium – 0,35% max. | |

| Phosphorus – 0,04% max | Density Alloy 825: 8,87 |

Titanium Grade 2 – UNS R50400

Applications Titanium Grade 2:

Titanium Grade 2 is a commercially pure Titanium (CP) and is the most commonly used type of Titanium for industrial applications. Titanium Grade 2 is used extensively for sea water piping, reactor vessels and heat exchangers in the (Petro)-chemical, Oil & Gas and Marine Industries. This is partly due to its low density and corrosion resistance and can be easily welded, hot and cold worked and machined.

| Chemical analysis Titanium Grade 2: | Titanium Grade 2 ASTM standards: |

| Carbon – 0,08% max. | Bar/Billet – B348 |

| Nitrogen – 0,03% max. | Forgings/Flanges – B381 |

| Oxygen – 0,25% max. | Seamless Tubing – B338 |

| Hydrogen – 0,015% max. | Welded Tubing – B338 |

| Iron – 0,3% max. | Seamless Pipe – B861 |

| Titanium – balance | Welded Pipe – B862 |

| Plate – B265 | |

| Density Titanium Grade 2: 4,50 | Buttweld fittings – B363 |

Hot Tags: alloy wire manufacturers, suppliers, price, for sale

Product detail pictures:

Related Product Guide:

Stainless Steel Bar Tops In the Great British Pub

How to Save Time and Cost With a 316 Stainless Steel Bar

It can be our accountability to satisfy your preferences and competently provide you. Your satisfaction is our greatest reward. We are searching ahead towards your visit for joint growth for 18 Years Factory Stainless Steel Flat Rod - Alloy Wire – Saky Steel, The product will supply to all over the world, such as: Chile , United Arab Emirates , Malaysia , We pay high attention to customer service, and cherish every customer. We've maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!