18 Years Factory Stainless Damascus Steel Bar - Brushed Stainless Steel Sheet – Saky Steel

18 Years Factory Stainless Damascus Steel Bar - Brushed Stainless Steel Sheet – Saky Steel Detail:

Specifications:AISI 304/304L,ASTM A240, AMS 5513/5511

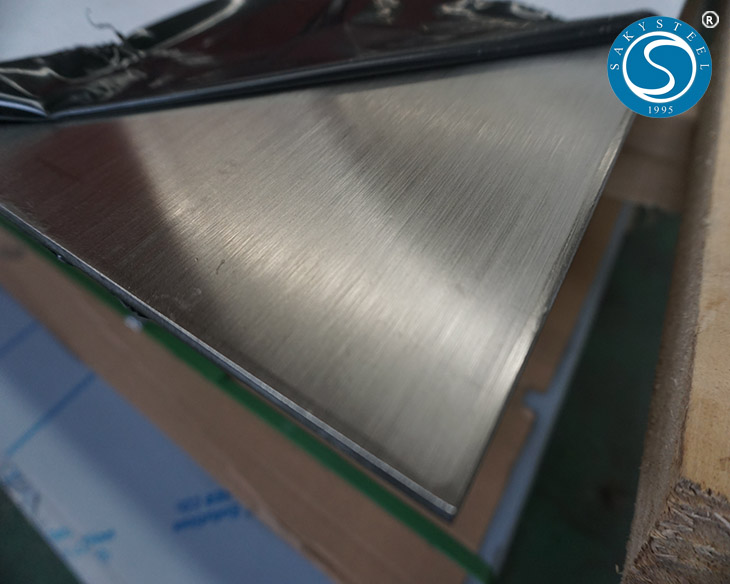

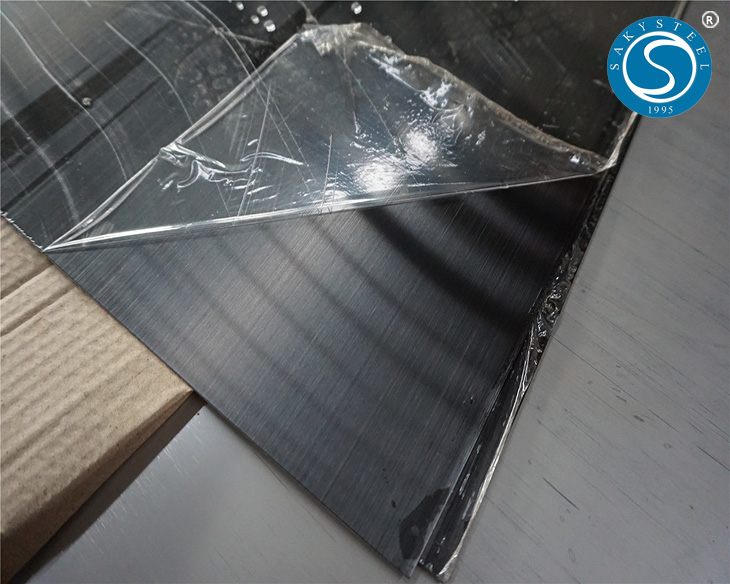

·Finishes: 2B Mill (dull), #4 Brushed (appliances), #8 Mirror

·Applications: sanitary dairy, beverage and food product handling and processing, hospital equipment, marine hardware, kitchen appliances, back splashes, etc.

·Workability:Easy to Weld, Cut, Form and Machine with proper equipment

·Mechanical Properties: Nonmagnetic,Tensile = 85,000 +/-, Yield = 34,000 +/-, Brinell = 170

·How is it Measured thickness X width X length

·Available Stock Sizes:1ft x 4ft, 2ft x 2ft, 2ft x 4ft, 4ft x 4ft, 4ft x 8ft, 4ft x 10ft or Cut to Size

| C% | Si% | Mn% | P% | S% | Cr% | Ni% | N% | Mo% | Cu% |

| =0.08 | =1.0 | =2.0 | =0.045 | =0.03 | 18.0-20.0 | 8.0-10.0 | – | - | – |

| T*S | Y*S | Hardness | Elongation | |

| (Mpa) | (Mpa) | HRB | HB | (%) |

| =520 | =205 | – | – | =40 |

Description of NO.4/grit/polished/hairline/brushed Stainless Steel Sheet,

| Product | 304 stainless steel sheet,stainless steel 304 2b,Stainless Steel 304 Sheet,304L Stainless Steel Sheet,304 stainless steel sheets,304 stainless steel data sheet,304 stainless steel thickness,ss 304 sheet |

| Grade | 302,303,304,304L,309, 309S,310S,316,316L,316Ti,317L,321,347H, 201,202,XM,409,409L,410, 410S, 420(420J1, 420J2), 430, 436, 439, 440C,441, 444,446 Duplex,Alloy Incoloy etc |

| Brand | SAKY,TISCO, BAOSTEEL, POSCO, JISCO, LISCO etc. |

| Certificate | ISO, SGS, BV, TUV,CE or as required |

| Thickness | 0.1mm-6mm |

| Width | 1000/1219/1220/1250/1500/1800/2000mm or as required |

| Length | 2000/2438/2500/3000/6000/12000mm or as required |

| Surface | 2B,No.1,No.4,No.8,BA,8K,Hairline,Brush,MIRROR,2D |

| Standard | ASTM,AISI,SUS,JIS,EN,DIN,BS,GB,etc |

More details brushed Stainless Steel Sheet Plate

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Applications of CR stailess steel sheet:

1: Construction feild,shipping building industry

2: Petroleum and Chemical Industries

3: Food and Machenical Industries

4: Boiler Heat Exchange

5: Machinery and Hardware Industries

More grades of stainless steel sheet stock

| Type | Grade | Grade | Chemical Component % | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Other | |||

| Austenitic stainless steel | 201 | 1Cr17Mn6Ni5N | =0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | =0.060 | =0.030 | - | =1.00 | - | =0.25 | - |

| 201L | 03Cr17Mn6Ni5N | =0.030 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | =0.060 | =0.030 | =1.00 | =0.25 | ||||

| 202 | 1Cr18Mn8Ni5N | =0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | =0.060 | =0.030 | =1.00 | - | =0.25 | - | ||

| 204 | 03Cr16Mn8Ni2N | =0.030 | 15.00-17.00 | 1.50-3.50 | 7.00-9.00 | 0.15-0.30 | |||||||

| 1Cr18Mn10Ni5Mo3N | =0.10 | 17.00-19.00 | 4.00-6.00 | 8.50-12.00 | 2.80-3.50 | 0.20-0.30 | |||||||

| 2Cr13Mn9Ni4 | 0.15-0.25 | 12.00-14.00 | 3.70-5.00 | 8.00-10.00 | |||||||||

| 2Cr15Mn15Ni2N | 0.15-0.25 | 14.00-16.00 | 1.50-3.00 | 14.00-16.00 | 0.15-0.30 | ||||||||

| 1Cr18Mn10Ni5Mo3N | =0.15 | 17.00-19.00 | 4.00-6.00 | 8.50-12.00 | =0.060 | =0.030 | 2.8-3.5 | =1.00 | - | 0.20-0.30 | - | ||

| 301 | 1Cr17Ni7 | =0.15 | 16.00-18.00 | 6.00-8.00 | =2.00 | =0.065 | =0.030 | - | =1.00 | - | - | - | |

| 302 | 1Cr18Ni9 | =0.15 | 17.00-19.00 | 8.00-10.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 303 | Y1Cr18Ni9 | =0.15 | 17.00-19.00 | 8.00-10.00 | =2.00 | =0.20 | =0.030 | 1) | =1.00 | - | - | - | |

| 303se | Y1Cr18Ni9Se | =0.15 | 17.00-19.00 | 8.00-10.00 | =2.00 | =0.20 | =0.030 | - | =1.00 | - | - | Se=0.15 | |

| 304 | 0Cr18Ni9 | =0.07 | 17.00-19.00 | 8.00-10.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 304L | 00Cr19Ni10 | =0.030 | 18.00-20.00 | 8.00-10.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 304N1 | 0Cr19Ni9N | =0.08 | 18.00-20.00 | 7.00-10.50 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | 0.10-0.25 | - | |

| 304N2 | 0Cr18Ni10NbN | =0.08 | 18.00-20.00 | 7.50-10.50 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | 0.15-0.30 | Nb=0.15 | |

| 304LN | 00Cr18Ni10N | =0.030 | 17.00-19.00 | 8.50-11.50 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | 0.12-0.22 | - | |

| 305 | 1Cr18Ni12 | =0.12 | 17.00-19.00 | 10.50-13.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 309S | 0Cr23Ni13 | =0.08 | 22.00-24.00 | 12.00-15.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 310S | 0Cr25Ni20 | =0.08 | 24.00-26.00 | 19.00-22.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 316 | 0Cr17Ni12Mo2 | =0.08 | 16.00-18.50 | 10.00-14.00 | =2.00 | =0.035 | =0.030 | 2.00-3.00 | =1.00 | - | - | - | |

| 1Cr18Ni12Mo2Ti6) | =0.12 | 16.00-19.00 | 11.00-14.00 | =2.00 | =0.035 | =0.030 | 1.80-2.50 | =1.00 | - | - | Ti5(C%-0.02)~0.08 | ||

| 0Cr18Ni12Mo2Ti | =0.08 | 16.00-19.00 | 11.00-14.00 | =2.00 | =0.035 | =0.030 | 1.80-2.50 | =1.00 | - | - | Ti5*C%-0.70 | ||

| 316L | 00Cr17Ni14Mo2 | =0.030 | 16.00-18.00 | 12.00-15.00 | =2.00 | =0.035 | =0.030 | 2.00-3.00 | =1.00 | - | - | - | |

| 316N | 0Cr17Ni12Mo2N | =0.08 | 16.00-18.00 | 10.00-14.00 | =2.00 | =0.035 | =0.030 | 2.00-3.00 | =1.00 | - | 0.10-0.22 | - | |

| 316N | 00Cr17Ni13Mo2N | =0.030 | 16.00-18.50 | 10.50-14.50 | =2.00 | =0.035 | =0.030 | 2.00-3.00 | =1.00 | - | 0.12-0.22 | - | |

| 316J1 | 0Cr18Ni12Mo2Cu2 | =0.08 | 17.00-19.00 | 10.00-14.50 | =2.00 | =0.035 | =0.030 | 1.20-2.75 | =1.00 | 1.00-2.50 | - | - | |

| 316J1L | 00Cr18Ni14Mo2Cu2 | =0.030 | 17.00-19.00 | 12.00-16.00 | =2.00 | =0.035 | =0.030 | 1.20-2.75 | =1.00 | 1.00-2.50 | - | - | |

| 317 | 0Cr19Ni13Mo3 | =0.12 | 18.00-20.00 | 11.00-15.00 | =2.00 | =0.035 | =0.030 | 3.00-4.00 | =1.00 | - | - | - | |

| 317L | 00Cr19Ni13Mo3 | =0.08 | 18.00-20.00 | 11.00-15.00 | =2.00 | =0.035 | =0.030 | 3.00-4.00 | =1.00 | - | - | - | |

| 1Cr18Ni12Mo3Ti6 | =0.12 | 16.00-19.00 | 11.00-14.00 | =2.00 | =0.035 | =0.030 | 2.50-3.50 | =1.00 | - | - | Ti5(C%-0.02)~0.08 | ||

| 0Cr18Ni12Mo3Ti | =0.08 | 16.00-19.00 | 11.00-14.00 | =2.00 | =0.035 | =0.030 | 2.50-3.50 | =1.00 | - | - | Ti5*C%-0.70 | ||

| 317J1 | 0Cr18Ni16Mo5 | =0.040 | 16.00-19.00 | 15.00-17.00 | =2.00 | =0.035 | =0.030 | 4.00-6.00 | =1.00 | - | - | - | |

| 321 | 1Cr18Ni9Ti6 | =0.12 | 17.00-19.00 | 8.00-11.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | Ti5(C%-0.02)~0.08 | |

| 0Cr18Ni10Ti | =0.08 | 17.00-19.00 | 9.00-12.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | Ti=5*C% | ||

| 347 | 0Cr18Ni11Nb | =0.08 | 17.00-19.00 | 9.00-13.00 | =2.00 | =0.035 | =0.030 | - | =1.00 | - | - | Nb=10*C% | |

| XM7 | 0Cr18Ni9Cu3 | =0.08 | 17.00-19.00 | 8.50-10.50 | =2.00 | =0.035 | =0.030 | - | =1.00 | 3.00-4.00 | - | - | |

| XM15J1 | 0Cr18Ni13Si4 | =0.08 | 15.00-20.00 | 11.50-15.00 | =2.00 | =0.035 | =0.030 | - | 3.00-5.00 | - | - | 2) | |

| Austenite | Ferrite Stainless Steel |

329J1 | 0Cr26Ni5Mo2 | =0.08 |

Product detail pictures:

Related Product Guide:

Stainless Steel Bars – Production, Importance, and Uses

How to Save Time and Cost With a 316 Stainless Steel Bar

Adhering for the theory of "quality, services, performance and growth", we have received trusts and praises from domestic and worldwide shopper for 18 Years Factory Stainless Damascus Steel Bar - Brushed Stainless Steel Sheet – Saky Steel, The product will supply to all over the world, such as: Latvia , kazakhstan , Denmark , Our experience makes us important in our customer eyes. Our quality speaks itself the properties like it do not tangle, shed or breakdown, so that are our customers will always be confident while placing an order.

A good manufacturers, we have cooperated twice, good quality and good service attitude.