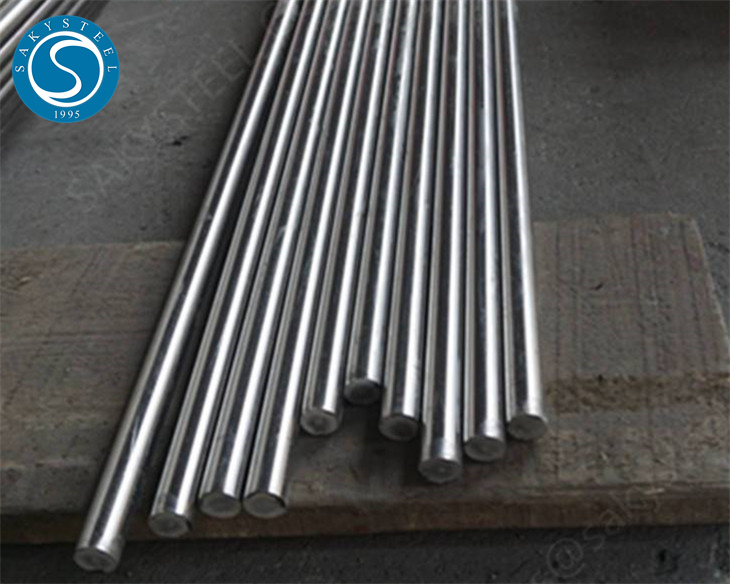

1.4923 X22CrMoV12-1 Round Bars

Short Description:

Discover 1.4923 X22CrMoV12-1 round bars ideal for high-temperature applications like turbines and boilers. Explore properties, dimensions, and customization options.

1.4923 X22CrMoV12-1 Round Bars:

1.4923 (X22CrMoV12-1) round bars are high-strength, heat-resistant alloy steel bars designed for applications in extreme environments. With excellent resistance to high temperatures and oxidation, they are commonly used in turbine blades, boiler components, and high-pressure piping systems. This material offers a balanced composition of chromium, molybdenum, and vanadium, ensuring superior mechanical properties, including high tensile strength, toughness, and durability, even at elevated temperatures up to 600°C. Ideal for industries requiring reliability under thermal stress, 1.4923 round bars meet stringent DIN and EN standards, ensuring consistent quality and performance.

Specifications Of X22CrMoV12-1 Round Bar:

| Ultrasonic Test Standard | DIN EN 10269 |

| Grade | 1.4923, X22CrMoV12-1 |

| Length | 1-12M & Required Length |

| Surface Finish | Black, Bright |

| Form | Round |

| End | Plain End, Beveled End |

| Mill Test Certificate | EN 10204 3.1 or EN 10204 3.2 |

1.4923 Round Bar Equivalent Grades:

| DIN | WERKSTOFF NR. | AISI |

| X22CrMoV12-1 | 1.4923 | X22 |

X22CrMoV12-1 Round Bar Chemical Composition:

| C | Mn | P | S | Si | Cr | Ni | Mo |

| 0.18-0.24 | 0.4-0.9 | 0.025 | 0.015 | 0.50 | 11.0-12.5 | 0.3-0.8 | 0.8-1.2 |

1.4923 Steel Bars Mechanical properties :

| Material | Yield Strength (Mpa) | Tensile Strength (Mpa) | Hardness |

| 1.4923 | 600 | 750-950 | 240-310 HBW |

Features of 1.4923 Steel (X22CrMoV12-1):

1.Excellent Heat Resistance:1.4923 steel maintains stable mechanical properties under high temperatures (up to 600°C), making it ideal for long-term use in high-temperature and high-pressure environments.

2.High Strength and Toughness:With high tensile strength (750-950 MPa) and exceptional toughness, this steel ensures reliable performance under thermal and mechanical stress.

3.Oxidation and Corrosion Resistance:Its alloy composition, featuring high chromium (10.5-12.5%) and molybdenum (0.9-1.2%), provides excellent resistance to oxidation and corrosion in elevated temperature conditions.

4.Good Heat Treatability:1.4923 steel can be optimized through quenching and tempering, enhancing its hardness, strength, and toughness to meet diverse engineering requirements.

5.Wide Industrial Applications:Commonly used in components exposed to high temperatures and pressures, such as:Steam turbine blades,Boiler components,Heat exchangers,High-pressure piping,Compliance with International Standards.

Why Choose us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS TUV report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.

1.4923 Round Bar Packing:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,