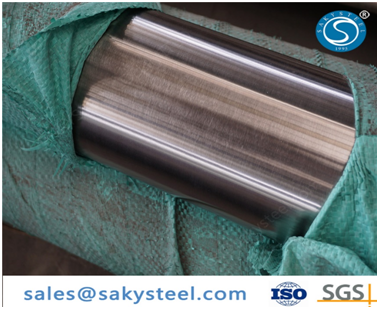

Introduction of Stainless steel grade 904L(UNS:N08904;EN:1.4539)

Grade 904L stainless steel is a non-stabilized austenitic stainless steel with low carbon content. This high alloy stainless steel is added with copper to improve its resistance to strong reducing acids, such as sulphuric acid. The steel is also resistant to stress corrosion cracking and crevice corrosion. Grade 904L is non-magnetic, and offers excellent formability, toughness and weldability.

Grade 904L contains high amounts of expensive ingredients, such as molybdenum and nickel. Today, most of the applications that employ grade 904L are replaced by low-cost duplex stainless steel 2205.

1.Chemical composition:

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu | |

| 904L |

min. max. |

- 0.02 |

- 2 |

- 1 |

- 0.045 |

- 0.035 |

19 23 |

4 5 |

23 28 |

1 2 |

2.Mechanical properties of grade 904L stainless steels

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) | Brinell (HB) | ||||

| 904L | 490 | 220 | 36 | 70-90 typical | 150 |

3.Corrosion Resistance

Grade 904L stainless steels have excellent resistance to warm seawater and chloride attack. The high resistance of grade 904L against stress corrosion cracking is due to the presence of high amounts of nickel in its composition. Moreover, the addition of copper to these grades develops resistance to sulphuric acid and other reducing agents in both aggressive and mild conditions.

4.Heat Treatment

Grade 904L stainless steels can be solution heat-treated at 1090 to 1175°C, following by rapid cooling. Thermal treatment is suitable for hardening these grades.

5.Heat Resistance

Grade 904L stainless steels offer good oxidation resistance. However, the structural stability of this grade collapses at high temperatures, particularly above 400°C.

6.Applications

Some of the major applications of grade 904L stainless steels include:

- • Wiring in electrostatic precipitators

- • Oil refinery components

- • Seawater cooling devices

- • Gas scrubbing plants

- • Pulp and paper processing industries

- • Acetic, phosphoric and sulphuric acid processing plants

7.Comparison with 316L, 6Mo and 2205

| 316L |

A lower cost alternative, but with much lower corrosion resistance. |

| 6Mo |

A higher resistance to pitting and crevice corrosion is needed. |

|

2205: A very similar corrosion resistance, with the 2205 having higher mechanical strength, and at a lower cost to 904L. (2205 not suitable for temperatures above 300°C.) |

|

|

Super duplex |

Higher corrosion resistance is needed, together with a higher strength than 904L. |

OUR CERTIFICATION

Contact Us

- Contacts: Saky Steel

- sales@sakysteel.com

- Skype: saky.steel

- Tel: 0086-21 60446500;60446511

- Fax: 0086-21 51026334

- Address: A205 No.588 ZhuYuan Road,Shanghai,China 201112